HONYPLAS®PPS sheet rod equivalent Sulfide PPS Sheet

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | Enough |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,DAF,EXW,DES,DDU |

| Certificate: | ISO REACH ROHS SGS |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

HONYPLAS®PPS sheet an amorphous polymer offering continuous performance up to 340°F (170°C). With excellent resistance to flame and heat,PPS sheet is ideal for high strength/high heat applications, as well as applications requiring consistent dielectric properties over a wide frequency range. It is known as a cheaper alternative to PEEK despite having lower impact strength comparatively and a higher temperature threshold.PPS is also resistant to hydrolysis, highly resistant to acidic solutions, and capable of withstanding repeated autoclaving cycles.

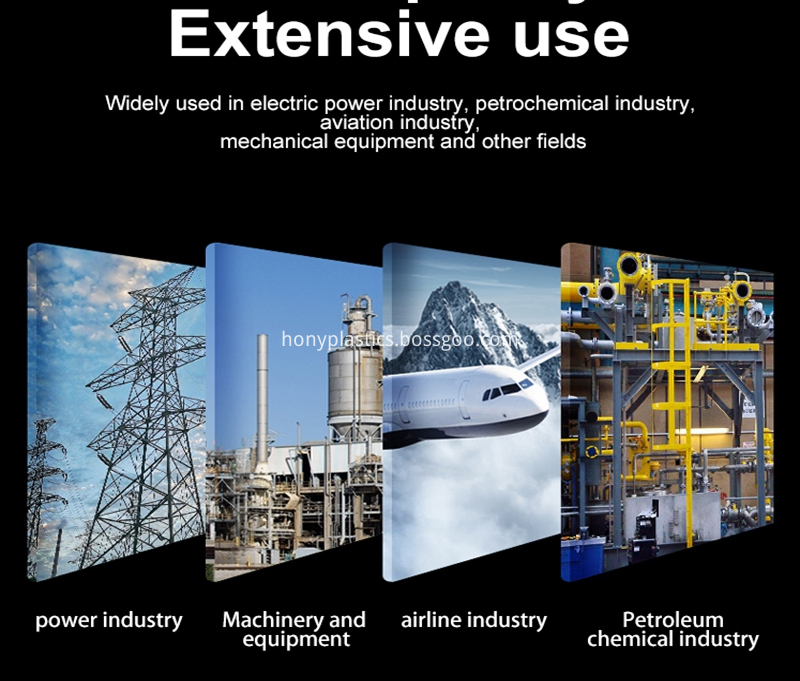

It is a thermoplastic engineering plastic material which is often used in Electronics & Electrical Appliances, Machinery, Chemical Anticorrosion, Aeronautics & Space and Military Industry.When material PA,POM.PET,PEI and PSU have defects, and material PI,PEEK, PAI cost too much,PPS is the best choice. With good internal lubricity and corrosion resistant, it is widely used in industrial equipment such as industry drying, food processing, chemical equipment and electrical insulation system.PPS - polyphenylene sulphide is a partially crystalline material that provides very high mechanical performance combined with excellent resistance to heat and chemicals (continuous service temperature resistance up to approximately + 464 °F), high dimensional stability and creep strength. Its is one of the highest among polymers. Excellent hardness and rigidity are other characteristics of PPS. By virtue of its strength and affordability, it bridges the gap between the partially crystalline industrial plastics and PEEK. Thanks to reinforcement with 40% glass fibres, strengths are attained that are comparable with light metals.

Main Product:

Related Keywords