PP Polypropylene Flame Retardant Board

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

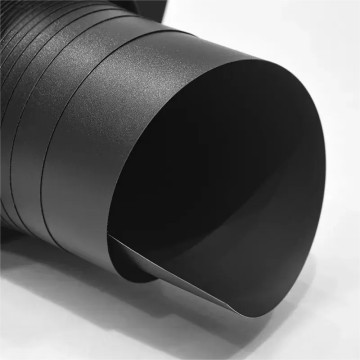

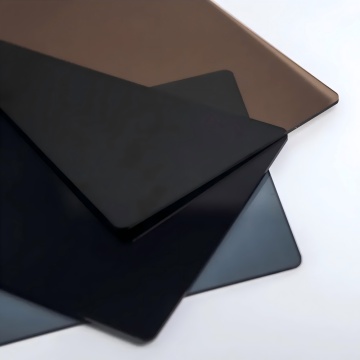

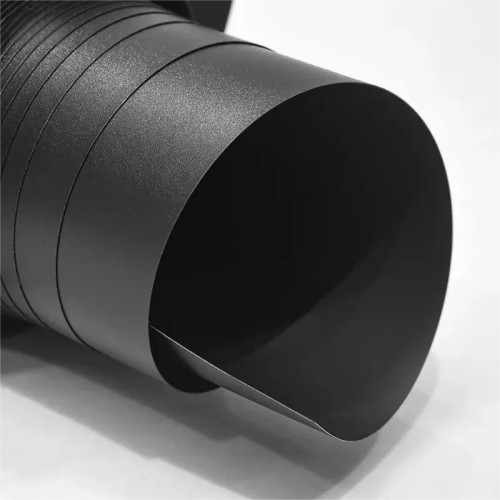

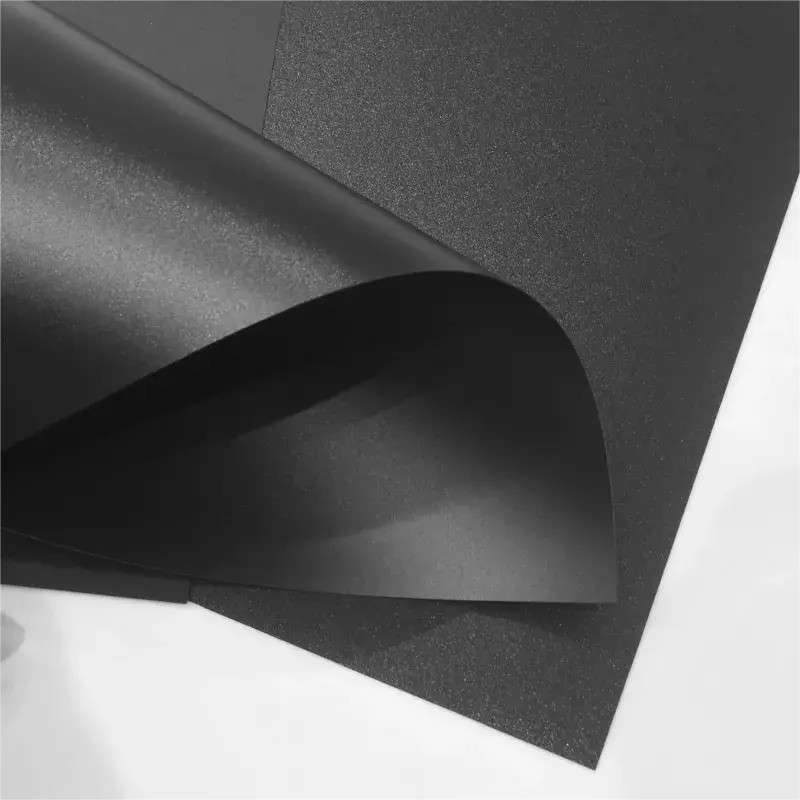

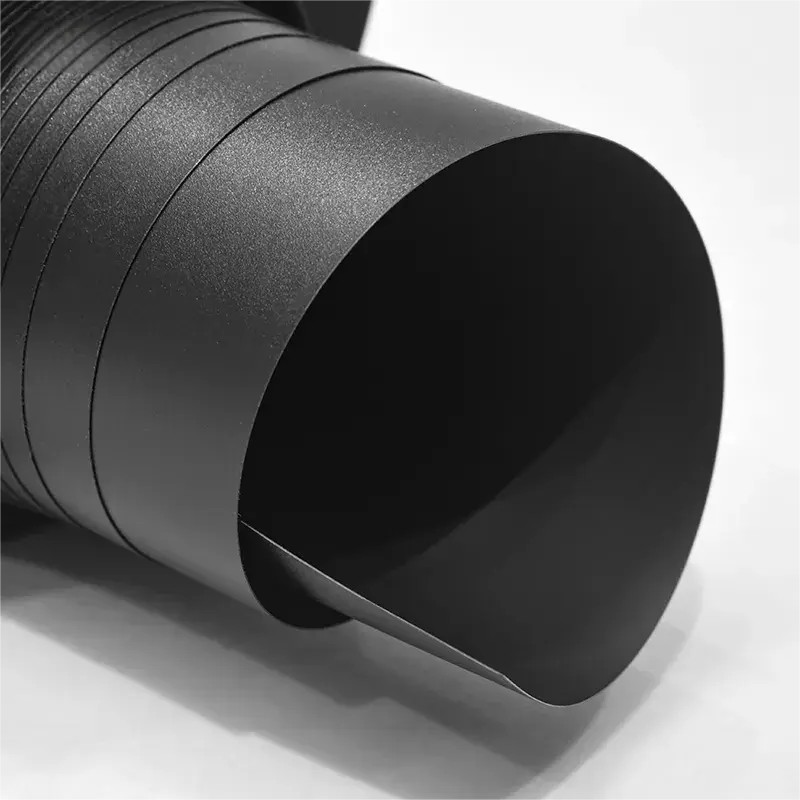

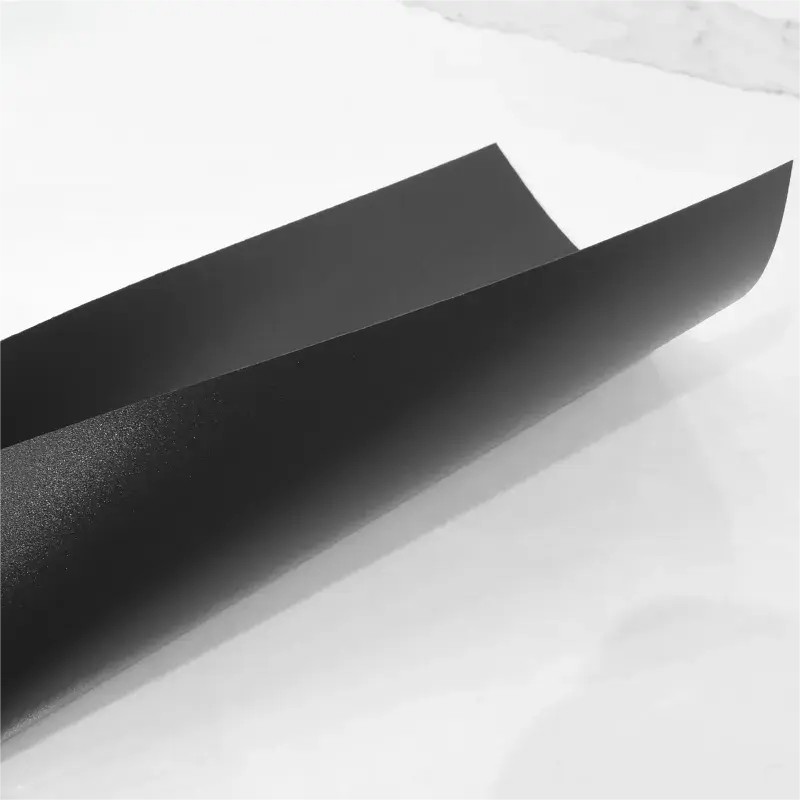

Flame retardant PP sheet:

Flame retardant PP sheet is made by adding flame retardant masterbatch to make PP sheet to achieve the effect of fire self-extinguishing. It has high stiffness, high hardness and high strength, but the notched impact resistance is very general. Flame retardant PP sheet can withstand tensile stress and is easy to weld. It becomes brittle at low temperatures and has excellent chemical stability and electrical properties. Operating temperatures range from 0 degrees to 100 degrees. Polypropylene has good heat resistance and the product can be sterilized at temperatures higher than 100°C and does not deform at 150°C without external force.

Ordinary PP sheet:

PP sheet, also known as polypropylene sheet, is a semi-crystalline material. It is harder than PE material and has higher melting point.PP extruded sheet has the characteristics of light weight, uniform thickness, smooth surface, good heat resistance, high mechanical strength, chemical stability and good electrical insulation.PP sheet is widely used in chemical containers, machinery, electronics, electrical appliances, food packaging, medicine, decoration and water treatment.PP sheet can be used at temperatures of up to 100 degrees Celsius.

Flame retardant PP and ordinary PP in the application of the difference is mainly reflected in the following aspects:

First, the nature of the material

Flame retardant PP: made by adding special additives such as flame retardants to PP resin, with flame retardant properties. Flame retardant is usually composed of bromine, oxygen, phosphorus, titanium, aluminum and other elements, a variety of types, each flame retardant performance and cost are different.

Ordinary PP: refers to pure PP resin without flame retardant added, so it does not have flame retardant properties.

Second, flame retardant effect

Flame-retardant PP: has good flame-retardant properties, can be self-extinguishing when encountering a fire source, reducing the risk of fire spread, thereby protecting the safety of people and property.

Ordinary PP: no flame retardant effect, easy to burn under the fire source, can not effectively prevent the spread of fire.

Third, the field of application

Flame retardant PP:

Furniture industry: used for furniture legs, table legs, chair legs, etc., to ensure that the furniture will not be burned in the fire, to protect the personal safety of the furniture inside.

Automobile industry: used in automobile seats, armrests, dashboards and other parts of the use of flame retardant PP materials to prevent smoke and fire in the fire, threatening the lives of passengers.

Electronic industry: used in the manufacture of electronic equipment shells, bases, etc., in order to protect the equipment from burning in the fire, to protect the safety of electronic components.

Construction industry: It is also used in construction materials, such as flame retardant PP sheets, to improve the fire performance of buildings.

Other fields: also widely used in machinery, food packaging, decoration and water treatment industries.

Ordinary PP:

Due to its excellent mechanical properties, such as high strength, abrasion resistance and corrosion resistance, ordinary PP is widely used in areas where these properties are needed.

In the packaging sector, PP plastic bags are one of the most common applications, used to package a wide range of products such as food, household goods and cosmetics.

In the automotive industry, ordinary PP is also used to make automotive interior parts, body parts and storage boxes to reduce vehicle weight, improve fuel efficiency and provide good impact resistance and durability.

Fourth, performance and cost

Flame retardant PP: Its performance is affected by flame retardants, which may be more complicated than ordinary PP. Excessive addition of flame retardants may lead to increased toxicity of the products and even cause serious pollution to the environment. Therefore, choosing the right flame retardant PP material requires comprehensive consideration of its performance and cost and other factors.

Ordinary PP: relatively stable performance, relatively low cost, suitable for routine applications that do not require flame retardant properties.

The core difference between flame retardant PP and ordinary PP is the difference in flame retardant properties, in addition to the composition, application scenarios and some physical properties also differ. The specific differences are as follows:

Compositional differences

Flame retardant PP is modified by adding flame retardants (such as halogen-antimony system, halogen-free expansion system, etc.) to ordinary PP resin, while ordinary PP is mostly pure resin without flame retardant treatment. The addition of flame retardant makes PP materials slow down burning or self-extinguishing in case of fire, and improves the flame retardant effect through the “PBr synergistic effect”.

Flame retardant properties

Flame retardant PP has obvious flame suppression ability, it is not easy to continue when burning, and the amount of smoke and low toxicity (especially halogen-free flame retardant system), which is suitable for occasions with high safety requirements (e.g., home appliances, automobile parts). Ordinary PP does not have such characteristics, flammable and continuous combustion.

Mechanical and thermal properties

Both in the tensile strength, compressive strength and other mechanical properties are similar, but flame retardant PP due to modification may slightly affect some of the characteristics (such as toughness, but in most cases still maintain excellent mechanical properties). The thermal stability (high temperature resistance, heat distortion temperature) of flame retardant PP is usually not lower than that of ordinary PP, and some of them are even better.

Processing and application scenarios

Both processing performance (fluidity, molding) is similar, but flame retardant PP may need to adjust the process parameters due to additives. Flame retardant PP is mainly used in electronic and electrical appliances, automobiles and other parts that need to be fireproof, while ordinary PP is used in general areas that do not need to be flame retardant.

Related Keywords

Related Keywords