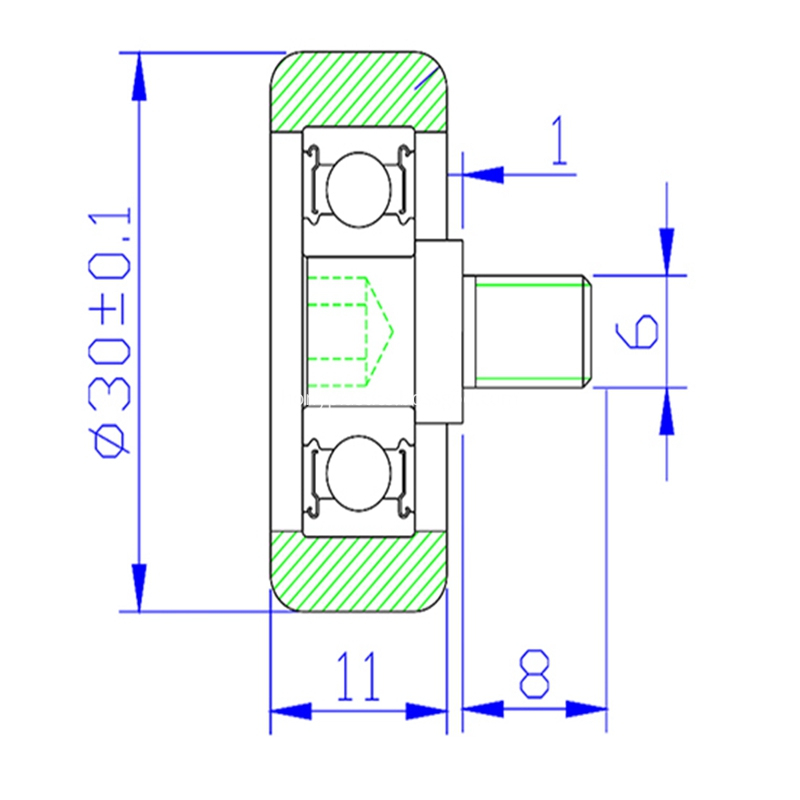

POM plastic roller wardrobe sliding door

-

$5.901-99 Piece/Pieces

-

$5.80100-999 Piece/Pieces

-

$5.70≥1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | Enough |

|---|---|

| Supply Ability: | Enought |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,DDU |

| Certificate: | ISO SGS REACH ROHS |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shenzhen,Guangzhou,Hongkong |

HONY®POM (polyoxymethylene resin): Polyoxymethylene is a linear polymer with no side chains, high density and high crystallinity. According to the different chemical structure in its molecular chain, it can be divided into two types: homopolyoxymethylene and copolyoxymethylene. The important difference between the two is: homopolyoxymethylene has high density, crystallinity, and melting point, but its thermal stability is poor, the processing temperature range is narrow (about 10℃), and its stability to acid and alkali is slightly lower; while the copolymer has high density, crystallinity, and The melting point and strength are low, but the thermal stability is good, it is not easy to decompose, the processing temperature range is wide (about 50 ℃), and the stability to acid and alkali is good. It is an engineering plastic with excellent comprehensive properties. It has good physical, mechanical and chemical properties, especially excellent friction resistance. Commonly known as Saigang or Duogang, it is the third largest general engineering plastic. It is suitable for making wear-reducing and wear-resistant parts, transmission parts, and chemical, instrument and other parts. A kind of synthetic resin, also known as polyoxymethylene resin, POM plastic, Saigang material, etc.; it is a kind of white or black plastic particles with high hardness, high rigidity and high wear resistance. Mainly used in gears, bearings, auto parts, machine tools, instrument internals and other products that play a role as skeletons.

Bearing plastic POM,Low friction POM/Nylon plastic coated bearings,High precision non standard plastic/POM/nylon coated bearing ,POM plastic coated bearings Good mechanical strength and wear resistance , suitable for the production of more sophisticated plastic bearings, working temperature from -60 °C ~ 100 °C.No constant maintenance required.Nomal used on Mechanical and electrical equipment, fitness equipment, food machinery, furniture, decorative materials.

Features :

(1) Rigidity, high hardness , even at low temperatures , high impact strength

(2) Good excellent elasticity , creep resistance ;

(3) High thermal stability and very good dimensional stability ;

(4) Good sliding properties , wear resistance ;

(5) Physiologically inert , suitable for contact with food.

(6) Even in strong acid and strong oxidizing agents, poor paint adhesion

Plastic bearings can be used for: Gear wheels, parts for pumps, screws, parts for the textile industry; The microelectronics industry, chemical, electroplating, pickling, semiconductor, piston rings, valve seats, gears, seals, aviation, plug connectors, wafer carriers. Pumps, Food Machinery; household appliances.

Plastic bearing Advantage

1. The plastic bearings are all lubricated materials and have a long service life;

2, Rusting and corrosion resistance will not occur during use, and metal bearings are easy to rust and cannot be used in chemical liquids;

3, The quality is lighter than metal, which is more suitable for modern lightweight design trends;

4, The manufacturing cost is lower than the metal; the injection molding process is more suitable for mass production;

5. There is no noise during operation and it has a certain vibration absorption function;

6, Plastic sliding bearings for high and low temperature work -200 ~ +250 degrees;

Main product

Related Keywords