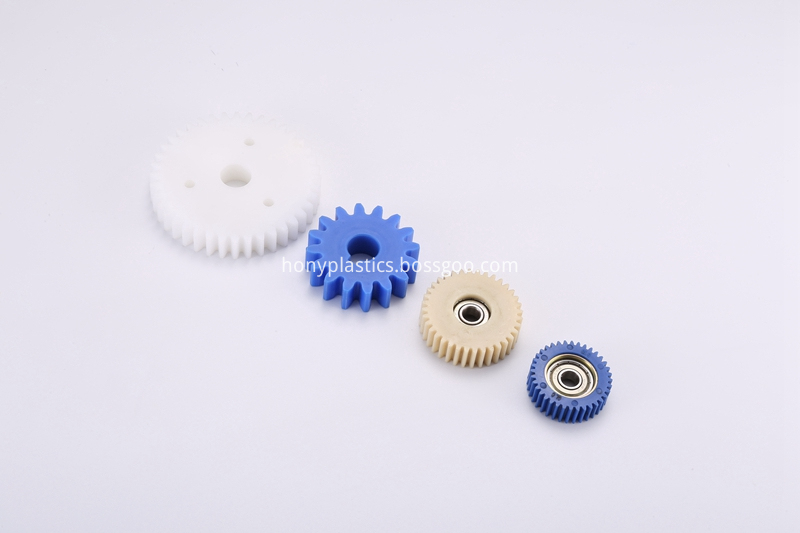

POM Plastic Spur Gear Pinion Gears Wheel

-

$5.901-99 Piece/Pieces

-

$5.80100-999 Piece/Pieces

-

$5.70≥1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | Enough |

|---|---|

| Supply Ability: | Enought |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,DDU |

| Certificate: | ISO SGS REACH ROHS |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shenzhen,Guangzhou,Hongkong |

HONY®Wear-resistant POM is a polyoxymethylene plastic with a special lubricant. Usually added materials are polytetrafluoroethylene (PTFE), chemical lubricants, etc., so that the wear-resistant POM plastic has an ultra-low friction coefficient and a lower shrinkage rate Rigidity, creep resistance, fatigue resistance, with the performance of engineering accessories, silent wear-resistant gears and other plastic parts.

POM plastic introduction:

Overview: crystalline thermoplastic plastic, with an obvious melting point of 165~175°C, the property is closest to metal, commonly known as plastic steel and steel material.

Advantage

1. With high mechanical strength and rigidity

2. The highest fatigue strength

3. Good environmental resistance and organic solvent resistance

4. Strong resistance to repeated impact

5. Wide operating temperature range (-40℃~120℃)

6. Good electrical properties

7. Good recovery

8. With self-lubricity and good wear resistance

9. Excellent size stability

Disadvantage

1. It is easy to heat and decompose under high temperature for a long time during processing

2. No self-extinguishing

3. Poor acid resistance

4. Large forming shrinkage

Commonly used materials for plastic gears are:

1: Wear-resistant POM/polyoxymethylene (POM)

2: Nylon (PA66 and PA46)

3: High-performance PP

4: High molecular weight PE

5: Polyphenylene sulfide (PPS)

6: Polyetheretherketone (PEEK)

In contrast, PA46, PPS, PEEK are often used in non-civilian fields, and the cost is too high;

High-performance PP and high-molecular-weight PE are relatively more expensive than POM plastics, have poor self-lubricity and low rigidity.

POM plastic has high strength, rigidity, good elasticity and good wear resistance. Its mechanical properties are excellent, the specific strength can reach 50.5MPa, and the specific stiffness can reach 2650MPa, which is very close to metal. The mechanical properties of POM change little with temperature, the impact strength of POM is high, and the fatigue strength of POM is very outstanding. After 10 alternating loads, the fatigue strength can reach 35MPa, while PA and PC are only 28MPa. The creep property of POM is similar to that of PA, only 2.3% at 20℃, 21MPa, 3000h, and it is not affected by temperature. POM has a small friction factor, good wear resistance, a large limit PV value, and good self-lubrication.

The wear-resistant POM plastic with special materials is greatly enhanced (self-lubricating, rigidity, creep resistance, fatigue resistance), the shrinkage rate is also greatly reduced, and the dimensional stability is guaranteed.

Gears are usually used in key parts such as mechanical transmission. As people's requirements for quality of life continue to increase, silence and stability are important considerations for electronic and household products. Wear-resistant POM has good performance in practice and is used in huge quantities.

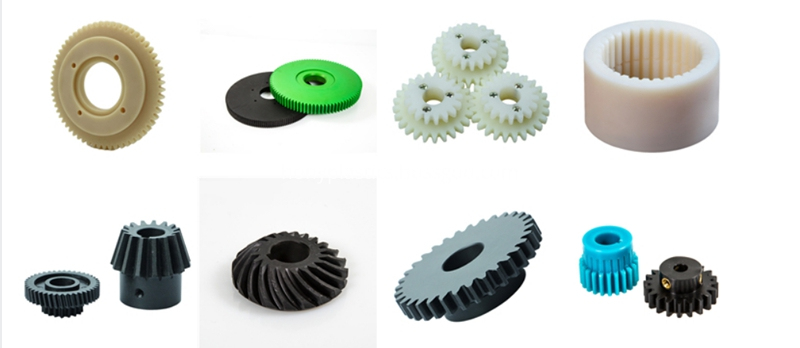

HONY offers various series of plastic gears and gear parts such as plastic worm gear, plastic spur gear, plastic helical gear, plastic pinion gear, plastic bevel gear, plastic gear rack. If you want to test it easily, rapid prototype can also provide to save cost and time(3-7days).

Plastic Gear VS Metal Gear

Plastic is inexpensive, corrosion resistant, quiet operationally and can overcome missing teeth or misalignment. Plastic is less robust than metal and is vulnerable to temperature changes and chemical corrosion. Acetal, delrin, nylon, and polycarbonate plastics are common.

HONY Service

1)Plastic gears material:Nylon;POM;UHMWPE

2)We manufacture plastic parts according to customers' designs;

3)We can offer material certification,test report and relate surface-treatment report;

4)Platic gears process:CNC machining,Milling,Drilling,Turning;

5)Products shown on the website are OEM;

6)The products shown here only to present the scope of our manufacturing activies,not for sale;

7)Customized designs are welcome;

8)Plastic gears OEM/ODM orders are welcome;

Main product

Related Keywords