High Strength POM Plastic Gears

-

$5.901-99 Piece/Pieces

-

$5.80100-999 Piece/Pieces

-

$5.70≥1000 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express, Others

- Port:

- Shenzhen, Guangzhou, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | Enough |

|---|---|

| Supply Ability: | Enought |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CIF,EXW,DDU |

| Certificate: | ISO SGS REACH ROHS |

| Transportation: | Ocean,Land,Air,Express,Others |

| Port: | Shenzhen,Guangzhou,Hongkong |

HONY®POM gears: POM mechanical properties are tough, fatigue-resistant, creep-resistant, low friction coefficient, and equal dynamic and static friction coefficients. POM is similar to PA in many aspects, but its fatigue resistance, creep resistance, rigidity and water resistance are better than PA. The crystallinity of POM is very high, ranging from 73% to 86%, which depends on the quenching temperature. When the temperature is changed from 0°C to 155°C, the crystallinity changes from 78% to 82%, and annealing treatment will increase the crystallinity. The greater the crystallinity, the higher the yield strength and tensile strength. Increasing the quenching temperature can increase the size of spherulites, but reduce the impact strength. The average degree of polymerization of POM is between 1010 and 1510, the number-average relative molecular mass is 3-48,000, and the relative molecular mass distribution is narrow.

Market application of POM as gears: The main application areas of POM can be used to manufacture vaporizer parts, oil pipes, pumps, power valves, bearings, universal joint bearings, gears, cranks, handles, handles, dashboards, bushings, shields, automobiles Lift window devices and electrical switches and safety devices on automobiles. POM is suitable for gears, chains, drive shafts, bearings, stem nuts, impellers, rollers, cams and various mechanical structural parts, electric tool housing handles, switches, etc. No leakage, high strength, and earthquake resistance. POM is used to manufacture various joints, plug-in components, switches, buttons, relays, turbines, power wheels of washing machines, various parts of household appliances, telephones, tape recorders, VCDs, video recorders, microwave ovens, rotating rods, sliding parts, precision The support frame, cover, friction pad of the instrument, the movement and precision parts of clocks, cameras, fax machines, etc., the gear separation claws of printers, laser copiers and other key components

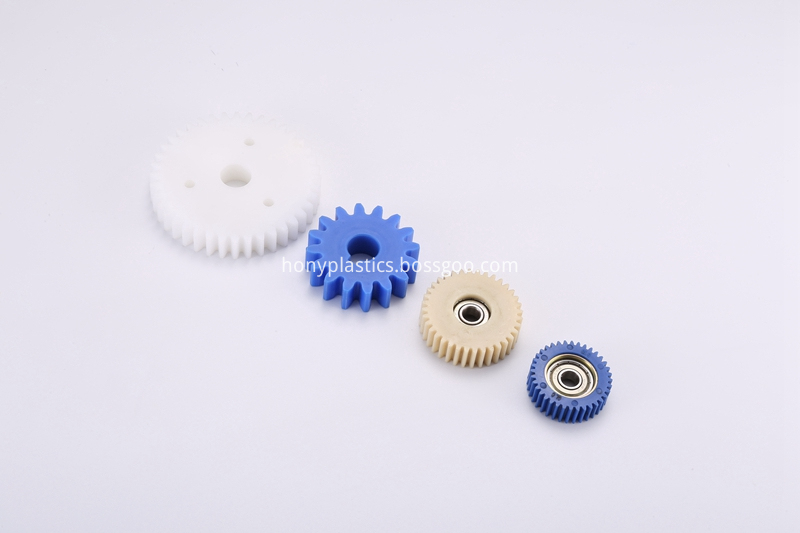

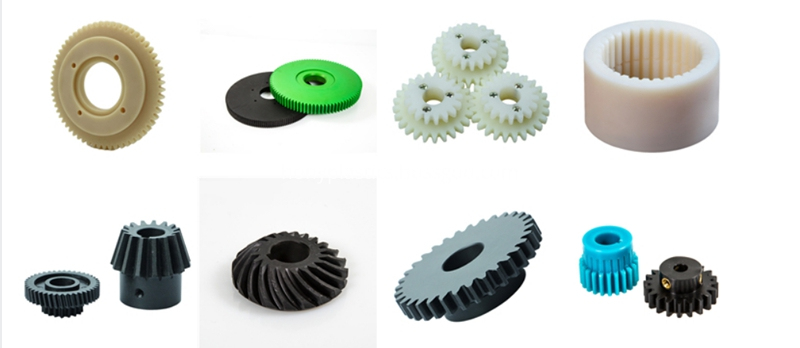

Gears are a crucial part of many motors and machines. Gears help increase torque output by providing gear reduction and they adjust the direction of rotation like the shaft to the rear wheels of automotive vehicles. Here are some basic types of gears and how they are different from each other.

HONY offers various series of plastic gears and gear parts such as plastic worm gear, plastic spur gear, plastic helical gear, plastic pinion gear, plastic bevel gear, plastic gear rack. If you want to test it easily, rapid prototype can also provide to save cost and time(3-7days).

Plastic Gear VS Metal Gear

Plastic is inexpensive, corrosion resistant, quiet operationally and can overcome missing teeth or misalignment. Plastic is less robust than metal and is vulnerable to temperature changes and chemical corrosion. Acetal, delrin, nylon, and polycarbonate plastics are common.

HONY Service

1)Plastic gears material:Nylon;POM;UHMWPE

2)We manufacture plastic parts according to customers' designs;

3)We can offer material certification,test report and relate surface-treatment report;

4)Platic gears process:CNC machining,Milling,Drilling,Turning;

5)Products shown on the website are OEM;

6)The products shown here only to present the scope of our manufacturing activies,not for sale;

7)Customized designs are welcome;

8)Plastic gears OEM/ODM orders are welcome;

Main product

Related Keywords