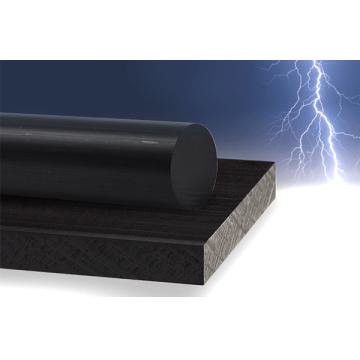

Vespel® Polyimide Rod Stock

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Hongkong, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Hongkong,Guangzhou |

Product Description

Product Description

PI sheets and rods refer to sheets and rods made from polyimide (PI) material. Polyimide is a high-performance polymer with excellent high-temperature resistance, mechanical strength, chemical resistance, and electrical insulation properties. The following is a detailed introduction to PI sheets and rods:

Properties of Polyimide (PI)

High-temperature resistance:

Can withstand long-term use at temperatures up to 260°C and short-term exposure to temperatures exceeding 400°C.

Maintains excellent mechanical properties and dimensional stability at high temperatures.

Mechanical strength:

High tensile strength and impact resistance.

Excellent wear resistance and creep resistance.

Chemical Resistance:

Excellent resistance to most organic solvents, acids, alkalis, and oils.

Electrical Properties:

Excellent insulation properties with a low dielectric constant, suitable for high-frequency electronic applications.

Radiation Resistance:

Excellent resistance to ultraviolet rays and γ rays.

Low Thermal Expansion Coefficient:

Minimal dimensional changes at high temperatures, suitable for precision components.

Main Applications of PI Sheets and Rods

Aerospace:

High-temperature insulating components, bearings, and seals.

Lightweight structural components.

Electronics and Electrical:

Insulating gaskets, circuit board substrates, and connectors.

High-frequency electronic components.

Automotive Industry:

High-temperature components in engine compartments and sensor housings.

Industrial Applications:

High-temperature-resistant seals, bearings, and slides.

Corrosion-resistant components in chemical processing equipment.

Medical Applications:

High-temperature sterilization instruments, implant prototypes.

PI Sheet and Rod Processing Methods

Machining:

PI sheets and rods can be machined into various shapes using turning, milling, drilling, and other methods.

Sharp tools must be used during processing to prevent material delamination or cracking.

Hot pressing:

PI sheets are formed into complex shapes through heating and pressure.

Adhesive bonding:

PI rods are bonded to other materials using high-temperature-resistant adhesives.

Advantages of PI rods

Maintains excellent performance under extreme conditions (high temperature, high pressure, corrosive environments).

Suitable for manufacturing high-precision, high-reliability parts.

Excellent electrical insulation properties, suitable for electronic and electrical applications.

Specifications of PI sheets and rods

Parameters

Typical values or ranges

Sheet thickness: 0.5 mm to 50 mm

Rod diameter: 5 mm to 200 mm

Color: Typically amber or brown

Density: 1.4 to 1.6 g/cm³

Long-term operating temperature: -269°C to +260°C

Alternative materials for PI sheets and rods

If the cost or processing difficulty of PI sheets and rods is high, the following alternative materials can be considered:

PEEK (polyetheretherketone):

Slightly lower high-temperature resistance than PI, but better processing performance.

PPS (polyphenylene sulfide):

Lower cost, but inferior to PI in terms of temperature resistance and mechanical properties.

PTFE (polytetrafluoroethylene):

Excellent chemical resistance, but lower mechanical strength.

Summary

PI sheets and rods are high-performance materials suitable for applications requiring high temperatures, high strength, and chemical corrosion resistance. They have widespread applications in aerospace, electronics, and industrial fields.

PI rod material breaks through the limits of engineering plastics with its high-temperature stability at 260°C and insulation performance of 101 Ω·cm. It achieves a 30% weight reduction in aerospace applications and a 40% reduction in 5G signal loss. Despite its unit price of 800 yuan per kilogram, it offers a comprehensive cost advantage due to its 8-year maintenance-free lifespan, driving innovation in the semiconductor and new energy industries.

In the vast field of engineering plastics, PI rods (polyimide rods) have gradually become the material of choice for high-end industrial applications due to their outstanding comprehensive performance. This high-performance specialty engineering plastic not only maintains stability in extreme environments but also possesses lightweight, corrosion-resistant, and insulating properties that traditional metal materials cannot match, making it stand out in fields such as aerospace, electronics, and precision machinery. So, how exactly do PI rods push the boundaries of engineering plastic performance? The underlying technical logic and market value warrant further exploration.

I. Extreme Performance: Redefining the Boundaries of Engineering Plastics

The molecular structure of polyimide endows PI rod stock with nearly “all-purpose” properties. Its main chain contains rigid aromatic heterocyclic structures, and the intermolecular forces between chains are extremely strong, enabling the material to maintain stable performance under extreme conditions such as high temperatures, high frequencies, and high radiation. According to experimental data, PI rod material can withstand long-term use temperatures exceeding 260°C, short-term temperatures exceeding 400°C, and a heat deflection temperature (HDT) exceeding 360°C, far surpassing the 250°C of PEEK (polyether ether ketone) and the 260°C of PTFE (polytetrafluoroethylene). For example, in the sealing components of aircraft engines, replacing metal with PI rod material reduces weight by over 30% while avoiding deformation failures caused by high temperatures.

In terms of dielectric properties, PI rod material has a volume resistivity of up to 10¹⁶ Ω·cm, a dielectric strength exceeding 25 kV/mm, and a dielectric loss tangent as low as 0.001 (at 1 MHz). These properties make it an ideal insulating material for high-frequency circuit boards in 5G communication base stations. Tests by a certain equipment manufacturer showed that RF connectors made from PI rods reduce signal transmission loss by 40% compared to traditional materials.

II. Technological Breakthrough: From Laboratory to Industrialization

The production of PI rods involves complex processes such as polycondensation reactions and imidization. Early products were limited to military use due to difficulties in forming and high costs, but recent process innovations have driven their transition to large-scale production. For example, the “two-step synthesis” technology—first preparing a soluble polyamide acid precursor, then undergoing high-temperature imidization—successfully addressed the issues of bubbles and cracks commonly associated with the traditional one-step method. A certain company has adopted modified nano-fillers (such as graphene/carbon fiber composite reinforcements), increasing the tensile strength of PI rods to 220 MPa, reducing the friction coefficient to 0.15, and extending the service life by more than five times.

In the field of processing, breakthroughs in precision turning technology are particularly critical. Due to the high hardness (Rockwell hardness M110) and brittleness of PI rods, traditional tools are prone to chipping. Currently, the industry uses diamond-coated tools combined with liquid nitrogen cooling processes to control processing accuracy within ±0.01 mm, meeting the stringent requirements for dimensional stability in semiconductor equipment.

III. Application Scenarios: From Replacing Metals to Opening New Markets

1. Aerospace Industry: PI rods are used to manufacture high-temperature-resistant bearings, missile fairings, and other components. The U.S. NASA utilized PI composite materials to fabricate an insulation shield for the Mars rover “Perseverance,” capable of withstanding 1,600°C aerodynamic heating.

2. Electronics and Electrical Field: As the core material for chip test sockets and FPC reinforcement plates, PI rod stock has a CTE (coefficient of thermal expansion) highly compatible with silicon chips (3×10⁻⁶/℃), resolving contact issues caused by temperature differences. In Huawei's 5G base stations, PI rod stock-made waveguide components reduce signal delay by 18%.

3. Medical implant field: Through surface biocompatibility modification, PI rods are used in artificial joints and dental implants. Clinical trials show that their wear resistance is 7 times higher than that of polyethylene materials, and there is no risk of metal ion leaching.

IV. Market competitiveness: Balancing cost and sustainability

Although PI rods are relatively expensive (approximately 800-1200 RMB/kg), their lifecycle cost advantages are significant. Taking automotive turbochargers as an example, although PI components are five times more expensive than aluminum alloy components, their maintenance-free nature and longer lifespan (8 years vs. 3 years for metal components) result in a 20% reduction in overall costs. Additionally, PI rods are recyclable, with a recovery rate exceeding 90% through chemical depolymerization technology, meeting the EU REACH regulation's restrictions on hazardous substances.

Related Keywords

Related Keywords