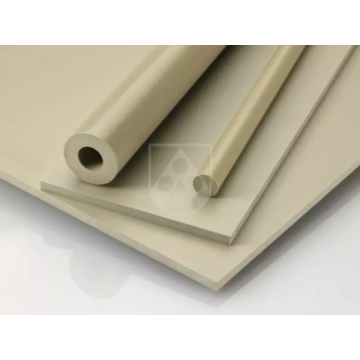

Engineering Plastic PEEK Rod High Quality Plastic Rods

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Hongkong, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 10000 |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Hongkong,Guangzhou |

Product Description

Product Description

PEEK rods are made from polyetheretherketone (PEEK) material.

PEEK rods, also known as polyetheretherketone rods in Chinese, are extruded using PEEK raw material. PEEK rods not only exhibit superior heat resistance compared to other high-temperature plastics but also feature high strength, high modulus, high fracture toughness, and excellent dimensional stability. PEEK rods have good toughness, and their fatigue resistance under alternating stress is the best among all plastics, comparable to alloy materials.

PEEK has excellent comprehensive properties, good mechanical properties, high-temperature resistance, and superior chemical resistance, making it the most versatile high-performance plastic.

Material Properties

1: High-temperature resistance — UL-certified for long-term use at 260°C. Even at temperatures as high as 300°C, it maintains excellent mechanical properties

Natural-colored PEEK sheet

2: Wear resistance: In extremely harsh application environments such as high temperatures, high loads, and strong corrosion, PEEK polymers and their composites exhibit excellent wear resistance.

3: Self-lubrication: It has a low coefficient of friction, enabling oil-free lubrication operation, and can operate long-term in media such as oil, water, steam, and weak acids/alkalis.

4: Corrosion resistance It is insoluble in common solvents and exhibits excellent corrosion resistance against various organic and inorganic chemical reagents.

5: High strength It possesses the best mechanical strength among plastics. It also exhibits high rigidity and surface hardness.

6: Easy to process Can be directly processed into parts using injection molding. Can undergo machining processes such as turning, milling, drilling, tapping, bonding, and ultrasonic welding.

7: Hydrolysis resistance Even when immersed in steam exceeding 250°C or high-pressure water, PEEK products can continue to operate for thousands of hours without significant performance degradation.

8: Flame resistance: Without any additives, a 1.45 mm thick PEEK sample achieves a UL94 V-0 flame resistance rating. 9: Low smoke and non-toxic: Emits extremely low levels of smoke and toxic gases when burned.

10: Electrical properties: Maintains stable and excellent electrical properties over a wide range of temperatures and frequencies.

11: Radiation Resistance: It exhibits exceptional resistance to high-dose gamma radiation, with mechanical properties fully retained, making it suitable for use as radiation-resistant components in nuclear equipment.

12: Dimensional Stability: PEEK sheet disadvantages: Injection molding processes are demanding, machining requirements are high, and strength is somewhat lower compared to metallic materials.

Grade and Color

1. PEEK-1000 (Brown-Gray)

Manufactured using pure polyetheretherketone resin as raw material, it has the best toughness and impact resistance among all PEEK grades. PEEK-1000 can be sterilized using the most convenient methods (steam, dry heat, ethanol, and gamma rays), and the raw materials used to manufacture PEEK-1000 comply with EU and US FDA regulations regarding food contact safety. These characteristics make it widely applicable in the medical, pharmaceutical, and food processing industries.

2. PEEK-HPV (black) — The addition of PTFE, graphite, and carbon fiber makes PEEK-HPV a bearing-grade plastic. Its superior friction properties (low friction coefficient, wear resistance, and high peak pressure limit) make it an ideal material for friction-related applications.

3. PEEK-GF30 (brown-gray) This material is a reinforced-grade plastic filled with 30% glass fiber, offering better stiffness, creep resistance, and dimensional stability than PEEK-1000, making it ideal for manufacturing structural parts. It can withstand fixed loads at high temperatures for extended periods. If PEEK-GF30 is used as a sliding component, its suitability should be carefully evaluated, as glass fibers may scratch mating surfaces.

4. PEEK-CA30 (Black) This material is reinforced with 30% carbon fiber, offering superior mechanical properties (higher elastic modulus, mechanical strength, and creep resistance) and better wear resistance compared to PEEK-GF30. Additionally, carbon fiber-reinforced plastic has 3.5 times the thermal conductivity of unreinforced PEEK plastic—enabling faster heat dissipation from bearing surfaces.

PEEK is a high-temperature, high-performance thermoplastic specialty engineering plastic. It has excellent mechanical properties and resistance to chemicals, wear, and hydrolysis; it is lightweight, has good self-lubricating properties, and due to its excellent processability, can be filled with carbon fiber, molybdenum disulfide, etc., to further enhance lubrication performance and mechanical strength. PEEK engineering plastics have a wide range of applications across high-tech industries such as aerospace, machinery, electronics, chemicals, and automotive, enabling the production of high-performance mechanical components such as gears, bearings, piston rings, support rings, seals (gaskets), valve plates, and wear-resistant rings.

The outstanding properties of PEEK material are primarily manifested in the following aspects:

High-temperature resistance

PEEK has a high glass transition temperature and melting point (334°C), which is one of the reasons it can be reliably used in applications requiring heat resistance. Its load-deflection temperature reaches 316°C, and its continuous use temperature is 260°C.

Mechanical properties

PEEK is a plastic that balances toughness and rigidity. In particular, its excellent fatigue resistance under alternating stress is unmatched among plastics and can rival that of alloy materials.

Self-lubricating properties

PEEK has outstanding sliding properties among all plastics, making it suitable for applications requiring low friction coefficients and wear resistance. In particular, PEEK modified with a certain proportion of carbon fiber and graphite exhibits even better self-lubricating properties.

Chemical resistance

PEEK has excellent chemical resistance. Among common chemicals, only concentrated sulfuric acid can dissolve or damage it. Its corrosion resistance is comparable to that of nickel steel.

Flame resistance

PEEK is a highly stable polymer. A 1.45mm-thick sample can meet the highest flame resistance standards without any flame retardants.

Peel resistance

PEEK has excellent peel resistance, enabling it to be used in thin-coated wires or electromagnetic wires under harsh conditions.

Fatigue resistance

PEEK has the best fatigue resistance among all resins.

Radiation resistance

It has strong resistance to γ-radiation, surpassing the best radiation resistance of polystyrene among general-purpose resins. It can be used to manufacture high-performance wires that maintain excellent insulation properties even at γ-radiation doses of up to 1100 Mrad.

Hydrolysis Resistance

PEEK and its composites are not chemically affected by water or high-pressure steam. Products made from this material maintain their excellent properties even when used continuously in high-temperature, high-pressure water.

Application Areas

Mechanical Industry

Due to its high-temperature resistance, corrosion resistance, fatigue resistance, and wear resistance, PEEK is widely used in components of various equipment both domestically and internationally, such as bearings, piston rings, and valve plates for reciprocating gas compressors.

Energy and Chemical Industry

Its excellent properties, including high-temperature resistance, high-humidity resistance, and radiation resistance, have been widely applied in the energy industry (e.g., nuclear power plants) and the chemical industry.

Applications in the Electronics and Information Industry Internationally, this is the second-largest application area for PEEK, accounting for approximately 25% of its usage. Especially in the transportation of ultra-pure water, pipes, valves, and pumps made from PEEK are essential to prevent contamination, and they are widely adopted overseas.

Aerospace Industry

Due to its superior comprehensive performance, PEEK has been widely used in aerospace products abroad since the 1990s. In China, it has been successfully tested in products for the J-8II fighter jet and the Shenzhou spacecraft.

Automotive Industry

Energy efficiency, weight reduction, and low noise are key requirements for automotive development. PEEK's lightweight, high mechanical strength, heat resistance, and self-lubricating properties perfectly meet the needs of the automotive industry.

Medical and Healthcare Field

In addition to being used to manufacture precision medical instruments, PEEK's most important application is as a substitute for metal in the production of artificial bones. It offers advantages such as lightweight, non-toxicity, and strong corrosion resistance, and can also integrate organically with the body, making it the material most similar to human bone.

PEEK is widely used in aerospace, healthcare, semiconductor, pharmaceutical, and food processing industries, such as components for gas analyzers on satellites and heat exchanger blades. Due to its superior friction properties, it is an ideal material for friction applications, including sleeve bearings, sliding bearings, valve seats, seals, and pump wear rings. Components for various production lines, semiconductor liquid crystal manufacturing equipment components, inspection equipment components, manufacturing fixtures, nuclear-related components, electronic components, various precision machine components, food processing line-related components, chemical machinery equipment-related components, welding machine-related components, gold plating processing machine-related components, metal surface treatment-related components, and thermal insulation components.

Related Keywords

Related Keywords