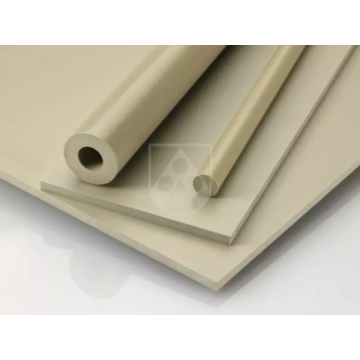

Antistatic 30% carbon Fiber Filled Peek sheet

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CIF,CFR,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

PEEK with 30% carbon fiber content actually means that the PEEK material is reinforced with 30% carbon fiber. After this treatment, the toughness, strength and processing performance of PEEK material will be improved. Specifically, the content of PEEK with 30% carbon fibers added is calculated based on the density relationship between PEEK and carbon fibers, which results in approximately 41%. This material is less likely to rupture when subjected to external impacts, is more durable, and maintains good performance in high-temperature and high-pressure environments. At the same time, the processing process is less likely to deformation, rupture and other problems .

PEEK vs. 30% Carbon Fiber Reinforced PEEK: Mechanical Properties vs.

Unreinforced PEEK has a tensile strength of 90-100 MPa and is suitable for chemical piping and electronic insulation; 30% carbon fiber reinforced PEEK doubles its strength to 180-220 MPa, which is just like concrete with steel reinforcement, making it the lightweight and high-strength choice for aerospace structural components and high-end sports equipment.

Unreinforced PEEK and 30% carbon fiber reinforced PEEK have significant differences in mechanical properties, the following is a detailed comparison for you:

Tensile Strength

Unreinforced PEEK: has a high tensile strength, typically around 90 - 100MPa. This makes it able to withstand a certain degree of tensile force without fracture, can be used for some of the strength requirements are not extremely high, but need good chemical stability and temperature resistance occasions, such as ordinary chemical pipeline lining, electronic and electrical appliances in some of the insulating parts.

30% Carbon Fiber Reinforced PEEK: With the addition of 30% carbon fiber, the tensile strength is greatly improved, usually reaching about 180 - 220MPa. The carbon fibers, which have very high tensile strength, are dispersed uniformly in the PEEK matrix and act as a reinforcing skeleton, like steel reinforcement in concrete, allowing the material to withstand greater tensile loads. This material is commonly used for structural components in aerospace, high-end sports equipment such as bicycle frames, golf clubs, etc. These application scenarios have stringent requirements for lightweight and high-strength materials.

Flexural Strength

Unreinforced PEEK: Flexural strength is typically around 130 - 150MPa. It is able to maintain a certain shape and structural integrity when subjected to bending forces, but may show significant deformation when the bending force is high. Suitable for some of the bending strength requirements are relatively low, the main concern of the material's corrosion and abrasion resistance occasions, for example, in some food processing equipment components, the material needs to be both wear-resistant and resistant to food media corrosion, unreinforced PEEK can meet the requirements.

30% carbon fiber reinforced PEEK: Flexural strength can be increased to about 250 - 300MPa. The addition of carbon fibers effectively improves the material's flexural capacity, enabling it to maintain better rigidity and shape stability when subjected to bending loads. In the automotive industry, it is used in the manufacture of parts that need to withstand large bending forces, such as automotive drive shafts, chassis components, etc., which can reduce weight while ensuring the performance and safety of the vehicle.

Hardness

Unreinforced PEEK: The hardness is relatively low, with a Shore D hardness of around 80 - 90. This makes it flexible and the surface is relatively easy to scratch, but the lower hardness has its advantages in some specific applications, such as where there is a need for a tight fit and sealing with other components, unreinforced PEEK is better able to adapt to different surface shapes, and achieve a good sealing result.

30% carbon fiber reinforced PEEK: The hardness is significantly increased, with Shore D hardnesses of around 95 - 100. The rigidity of carbon fiber makes the overall hardness of the material increase, the surface is more wear-resistant, and it can resist higher pressure and friction. It is suitable for the manufacture of parts that need to withstand friction and wear for a long period of time, such as wear-resistant bushings and gears in the machining process, etc., and it can effectively prolong the service life of the parts and improve the reliability of the equipments.

Impact strength

Unreinforced PEEK: has good impact toughness, impact strength is generally around 60 - 80kJ/m². This means that when it is impacted, it can absorb a certain amount of energy without brittle fracture, in some occasions that may be subjected to accidental impact, such as the shell of common industrial equipment, civil electronic products, etc., unreinforced PEEK can provide a certain degree of protection.

30% Carbon Fiber Reinforced PEEK: Impact strength is usually reduced, generally around 40 - 60kJ/m². Although the carbon fiber reinforcement increases the strength and rigidity of the material, the bonding interface between the carbon fibers and the PEEK substrate can become weak under impact loading, resulting in a relative reduction in the ability of the material to absorb impact energy. However, in some of the impact strength requirements are not particularly high, but the strength and rigidity of the strict requirements of the occasion, 30% carbon fiber reinforced PEEK can still meet the requirements of the use, such as in some industrial automation equipment frame structure, mainly subject to static and dynamic tensile, compression and bending loads, the impact strength requirements are relatively low.

In summary, unreinforced PEEK and 30% carbon fiber reinforced PEEK have their own characteristics in terms of mechanical properties, and the appropriate material should be selected according to specific application scenarios and performance requirements.

Related Keywords

Related Keywords