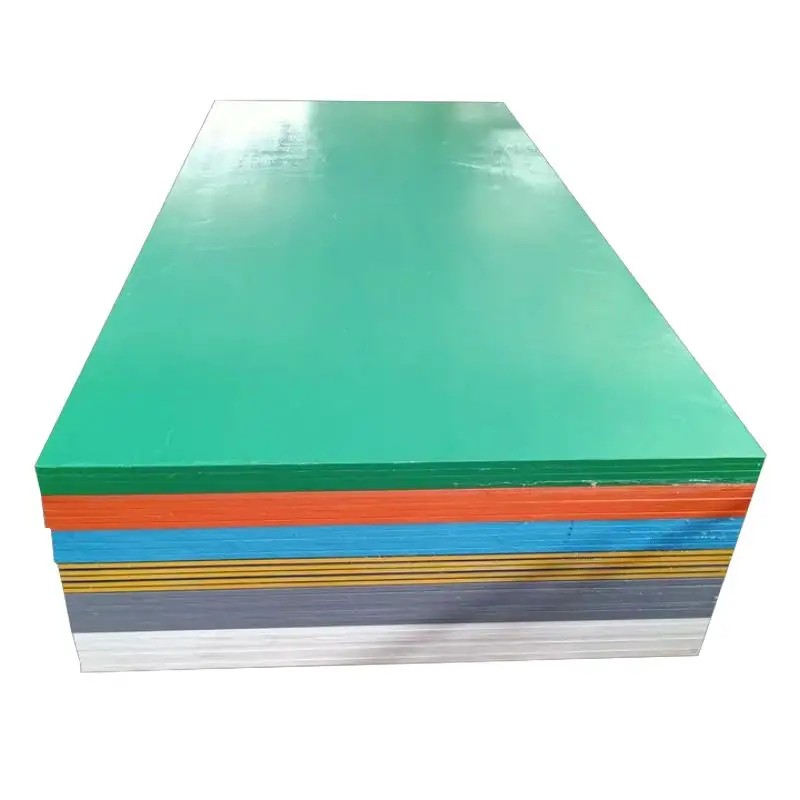

Low-Friction HDPE Cutting Board Polyethylene HDPE

- Min. Order:

- 1 Kilogram

- Min. Order:

- 1 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Hongkong, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Hongkong,Guangzhou |

Product Description

Product Description

High-density polyethylene (HDPE) is a white powder or granular product. It is non-toxic and odorless, with a crystallinity of 80%–90%, a softening point of 125–135°C, and a usable temperature up to 100°C. It has superior hardness, tensile strength, and creep resistance compared to low-density polyethylene. It also exhibits good wear resistance, electrical insulation, toughness, and low-temperature performance. It has excellent chemical stability and is insoluble in any organic solvent at room temperature. resistant to corrosion by acids, alkalis, and various salts; the film has low permeability to water vapor and air, and low water absorption; poor aging resistance, inferior environmental stress crack resistance compared to low-density polyethylene, especially thermal oxidation can degrade its performance, so antioxidants and UV absorbers must be added to the resin to improve these shortcomings. High-density polyethylene film has a lower thermal deformation temperature under stress, so caution is required during application.

【English Abbreviation】HDPE

【Full Chinese Name】High-Density Polyethylene

【Common Common Name】Low-Pressure Ethylene

【Monomer Composition】Ethylene

【Basic Properties】High-Density Polyethylene is an opaque white waxy material with a density lower than water, ranging from 0.941 to 0.960. It is soft and flexible but slightly harder than LDPE and has slightly less elongation. It is non-toxic and odorless.

【Combustion Characteristics】Flammable; continues burning after removal from flame. The flame has a yellow upper part and a blue lower part. It melts during combustion, with liquid droplets falling, no black smoke emitted, and emits a wax-like odor.

【Main Advantages】Resistant to acids and alkalis, resistant to organic solvents, excellent electrical insulation properties, and maintains some flexibility at low temperatures. Surface hardness, tensile strength, rigidity, and other mechanical properties are higher than LDPE,接近PP, more flexible than PP, but surface smoothness is inferior to PP.

【Main Disadvantages】Poor mechanical properties, poor breathability, prone to deformation, aging, and brittleness, with lower brittleness than PP, prone to stress cracking, low surface hardness, and prone to scratches. Difficult to print; surface discharge treatment is required during printing; cannot be electroplated; surface lacks luster.

【Applications】Used for extruded packaging films, ropes, woven bags, fishing nets, water pipes; injection-molded low-grade daily necessities and housings, non-load-bearing components, plastic boxes, and pallet boxes; extruded blow-molded containers, hollow products, and bottles.

【Injection Molding Process】HDPE has countless applications, ranging from reusable thin-walled beverage cups to 5-gallon containers, accounting for 1/5 of domestically produced HDPE. Injection molding grades typically have a melt index of 5–10, with grades featuring lower flow and higher flow for improved processability. Applications include thin-walled packaging for daily necessities and food; durable, flexible food and paint cans; and high environmental stress crack resistance applications, such as small engine fuel tanks and 90-gallon trash cans.

The melting point of general HDPE is 142°C, and the decomposition temperature is 300°C; the adjustable temperature range for injection molding is relatively wide. During injection molding, the typical operating temperature is 180°C–230°C; as an olefin-based plastic, it does not absorb water, so drying is not required during production. However, to ensure product quality, it can be dried at 60°C for 1 hour to remove surface moisture. Polyethylene has high melt viscosity and a low flow length ratio, so thin-walled products may experience insufficient material flow, resulting in larger gates and runners. The material is prone to static electricity and surface dust accumulation. The shrinkage rate is 16‰, and the flash allowance is 0.05 mm.

High-density polyethylene (HDPE) exhibits excellent heat resistance and cold resistance, along with good chemical stability. It also possesses high rigidity and toughness, as well as superior mechanical strength. Its dielectric properties and resistance to environmental stress cracking are also commendable. Its hardness, tensile strength, and creep resistance are superior to those of low-density polyethylene; its abrasion resistance, electrical insulation, toughness, and cold resistance are also good, but its electrical insulation properties are slightly inferior to those of low-density polyethylene; it has excellent chemical stability, being insoluble in any organic solvent at room temperature and resistant to corrosion by acids, alkalis, and various salts; its film has low permeability to water vapor and air, and low water absorption; it has poor aging resistance and inferior environmental crack resistance compared to low-density polyethylene, especially under thermal oxidation, which degrades its performance. Therefore, antioxidants and UV absorbers must be added to the resin to improve these shortcomings. High-density polyethylene film has a lower heat distortion temperature under stress, which should be noted during application.

Processing Methods

PE can be manufactured using a wide range of processing methods. Using ethylene as the primary raw material, along with copolymers such as propylene, 1-butene, and hexene, the polymer is produced through slurry polymerization or gas-phase polymerization processes under the action of a catalyst. The resulting polymer undergoes flash evaporation, separation, drying, and pelletization processes to obtain a finished product with uniformly sized particles. These include sheet extrusion, film extrusion, pipe or profile extrusion, blow molding, injection molding, and rotomolding. HDPE is suitable for various thermoplastic forming processes, offering excellent processability, such as injection molding, extrusion, blow molding, rotational molding, coating, foaming, thermoforming, heat sealing, and heat welding.

Extrusion: Grades used for extrusion production typically have a melt index (MI) less than 1 and a medium to wide molecular weight distribution (MWD). During processing, a lower MI provides suitable melt strength. Grades with a wider MWD are more suitable for extrusion because they offer higher production speeds, lower die pressure, and reduced tendency for melt fracture.

PE has numerous extrusion applications, such as wires, cables, hoses, pipes, and profiles. Pipe applications range from small-diameter yellow pipes for natural gas to thick-walled black pipes for industrial and municipal pipelines. Large-diameter hollow-wall pipes used as alternatives to concrete-made rainwater drainage pipes and other sewer lines are growing rapidly.

Sheets and thermoforming: Many large picnic-style refrigerated containers have thermoformed liners made from PE, which offers toughness, lightweight properties, and durability. Other sheet and thermoformed products include mudguards, tank liners, dish covers, transport boxes, and containers. A rapidly growing sheet application is geomembranes or pond liners, which are based on MDPE for its toughness, chemical resistance, and impermeability.

Blow molding: Over one-third of HDPE sold in the United States is used for blow molding applications. These range from bottles for bleach, motor oil, detergents, milk, and distilled water to large refrigerators, automotive fuel tanks, and drums. The characteristic properties of blow molding grades, such as melt strength, ES-CR, and toughness, are similar to those of grades used for sheet and thermoforming applications, so similar grades can be used.

Injection-blow molding is typically used to manufacture smaller containers (less than 16 oz) for packaging pharmaceuticals, shampoo, and cosmetics. One advantage of this process is that it automatically trims the edges of the bottles, eliminating the need for post-processing steps typical of conventional blow molding. While certain narrow MWD grades are used to improve surface finish, medium to wide MWD grades are generally employed.

Injection molding: See “Material Properties” above.

Rotational molding: Materials used in this process are typically ground into powder form, allowing them to melt and flow during thermal cycling. Rotational molding uses two types of PE: general-purpose and crosslinkable grades. General-purpose MDPE/HDPE typically has a density range of 0.935 to 0.945 g/cc, with a narrow MWD, resulting in high impact strength and minimal warpage. Its melt index (MI) range is generally 3–8. Higher MI grades are typically not suitable because they lack the impact strength and resistance to environmental stress cracking desired for rotomolded products.

Film: PE film processing generally uses conventional blown film processing or flat extrusion processing methods. Most PE used for film can be either general-purpose low-density PE (LDPE) or linear low-density PE (LLDPE). HDPE film grades are typically used where superior tensile strength and excellent barrier properties are required. For example, HDPE film is commonly used for shopping bags, grocery bags, and food packaging.

Main Applications

High-density polyethylene resin can be processed into plastic products using injection molding, extrusion, blow molding, and rotational molding methods. Injection molding can produce various types of containers, industrial components, medical supplies, toys, housings, bottle caps, and covers. Blow molding can produce various hollow containers and ultra-thin films. Extrusion molding can produce pipes, stretched strips, strapping bands, monofilaments, wires, and cable jackets.

Additionally, it can produce architectural decorative panels, blinds, synthetic wood, synthetic paper, synthetic films, and calcium plastic products.

Packaging and Storage

When storing, keep away from heat sources, insulate, keep the warehouse dry and clean, strictly prohibit the mixing of any impurities, and strictly prohibit exposure to sunlight or rain. Transportation should be stored in clean, dry, covered vehicles or ship holds, and must not contain sharp objects such as nails. Strictly prohibit mixed transportation with flammable aromatic hydrocarbons, halogenated hydrocarbons, and other organic solvents. For example, the four-liter mineral water drums used by Nongfu Spring are made from this material.

Related Keywords

Related Keywords