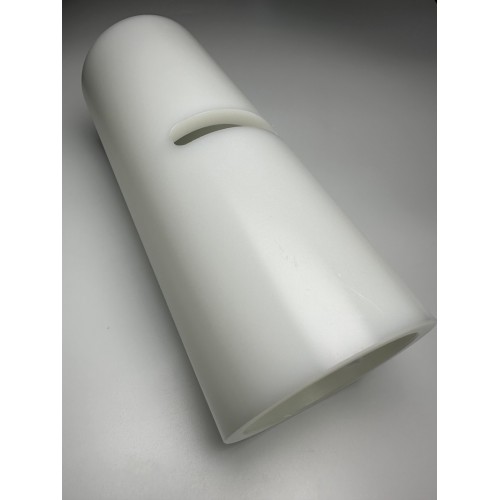

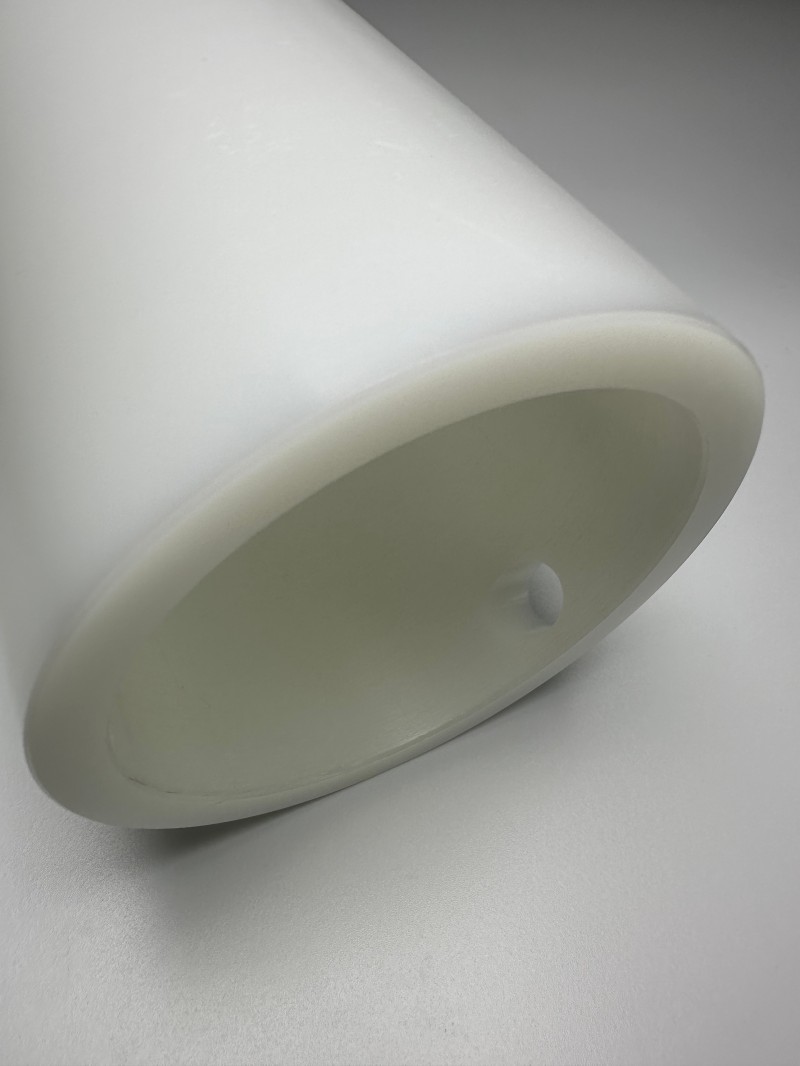

HDPE Machine Parts - Precision and Durability for CNC

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Hongkong, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 10000 |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Hongkong,Guangzhou |

Product Description

Product Description

PEHD (also known as HDPE), or high-density polyethylene, is a thermoplastic material that is commonly used in CNC machining for a variety of applications due to its strength, chemical resistance, and durability. CNC machining of PEHD involves using computer-controlled machines to precisely cut and shape the material according to a digital design.

Key Aspects of PEHD CNC Machining:

Material Properties:

PEHD is known for its high strength-to-density ratio, making it suitable for applications where both strength and weight are important. It also exhibits excellent chemical resistance and is durable, making it suitable for various environments.

CNC Machining Process:

CNC machining of PEHD involves using a cutting tool to remove material from a block of PEHD, following a pre-programmed path based on a digital design file. This process allows for the creation of complex shapes and tight tolerances.

Applications:

PEHD CNC machined parts are used in various industries, including medical, automotive, packaging, and consumer goods. They can be found in components like chemical tanks, playground equipment, electronic enclosures, and more.

Advantages:

PEHD offers a good balance of strength, flexibility, and chemical resistance compared to other plastics. It is also a safer option than PVC for certain applications due to the absence of harmful additives like phthalates.

Cost-effectiveness:

CNC machining of PEHD can be a cost-effective solution, especially for producing complex parts with tight tolerances.

In essence, PEHD CNC machining offers a reliable and efficient method for creating custom plastic parts with specific requirements for strength, chemical resistance, and precision.

HDPE CNC Machining | Material Properties and Applications

About HDPE for CNC Machining HDPE is sometimes called PEHD (polyethylene high-density) and is part of the polyethylene (PE) family

HDPE CNC Machining:CNC Milling Precision Plastic Parts

CNC Machining HDPE Parts High-density polyethylene (HDPE) is a versatile thermoplastic known for its excellent impact resistance

Related Keywords

Related Keywords