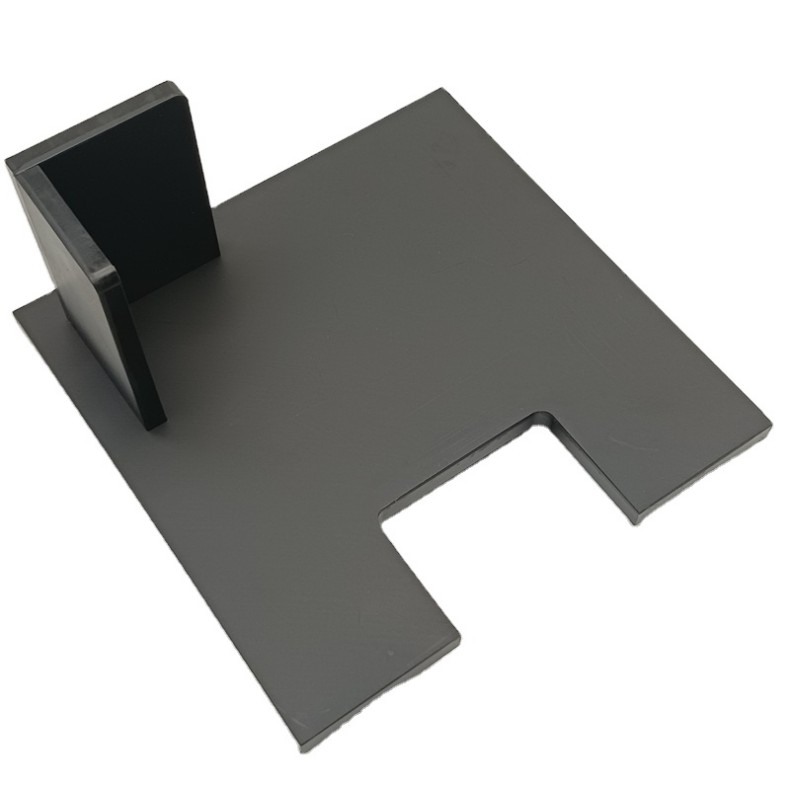

PA66 30%GF mechanical combination parts

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | Export package |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

First, PA66 +30% GF glass fiber reinforced nylon performance introduction:

Nylon chips after adding 30% glass fiber modification of its dimensional stability, heat resistance, aging resistance have been significantly improved, the material's tensile strength, bending strength has been substantially improved, fatigue strength and even increased more than 2.5 times, add 30% to 35% of the glass fiber, the material's overall mechanical properties of the best.

PA66 + 30% GF glass fiber reinforced nylon performance is shown in:

1. Improve the water absorption of nylon, improve the dimensional stability of products.

2. Improve the flame retardancy of nylon to meet the requirements of electronic, electrical, communication and other industries.

3. Improve the mechanical strength of nylon to reach the strength of metal materials and replace metal.

4. Improve the low-temperature resistance of nylon to enhance its ability to withstand environmental strains.

5. Improve the abrasion resistance of nylon, in order to adapt to the high abrasion resistance requirements of the occasion.

6. Improve the anti-static properties of nylon to meet the requirements of mining and its mechanical applications.

7. Improve the heat resistance of nylon to adapt to the field of high temperature resistant conditions such as automobile engines.

8. Reduce the cost of nylon to improve the competitiveness of products.

Second, the market application of PA66+30%GF.

1-Application in electrical and electronic market:

Small home appliance parts:CTQ: high strength, high toughness, high surface (appearance parts).

Commonly used materials:

Hair straightener:PA66+30%GF+V0;.

Bread machine outer cover: PA6+30%GF+HB.

Vacuum cleaner parts: PA6+30%GF+HB;; Vacuum cleaner parts: PA6+30%GF+HB.

Kettle holder: PA66+30%GF.

Electric kettle contactor: PA66+30%GF.

Juicer motor cover:PA66+30%GF.

Juicer switch bracket:PA66+30%GF.

Juicer switch plate:PA66+30%GF.

Juicer electric box cover:PA+30%GF.

Electric oven bottom door handle: PA66+30%GF.

Electric oven catch tray handle: PA66+30%GF.

Top cover of electric oven door handle: PA66+30%GF.

Lower cover of electric oven door handle: PA66+30%GF.

2-Application in automotive accessories market:

Automotive accessories CTQ (quality key point): high strength, special heat stabilization, hydrolysis resistance, applicable to automotive parts, mechanical parts, etc..

Automobile: bearing cage, cooling fan, door handle, gas cap, air intake grill, water tank cover, light socket, zip ties, etc.

Remarks: 1- For different valve cover requirements: if you require high rigidity, you can choose: PA66+35%GF; if you require low warping, you can choose: PA66+30%GF+15Mineral.

3-Electronic connectors: CTQ (quality key point): high fluidity, high toughness, high temperature resistance, easy to mold.

PCI slots, AGP slots, ISA slots.

Coil Backbone: CTQ: High strength, high toughness, high temperature resistance.

Coil Backbone: PA66+30%GF+HB, PA66+30%GF+V0.

Electrical Switches: CTQ: High toughness, high CTI, arc resistance.

Switch: PA66+30%GF+V0.

4-Circuit breaker accessories MCB: CTQ: low cost scorch wire.

MCB panel:PA66+30%GF+V0.

Motor Accessories:CTQ: High CTI value, high strength, high arc resistance, high temperature resistance.

Motor inner frame:PA66+30%GF+Halogen-free V0,...

Motor inner frame: PA66+30%GF+V0,

Motor rotor: PA66+30%GF+V0.

5-Applications of modified nylon in industrial/consumer goods market.

Power tool housing:CTQ: low cost, high appearance, easy molding.

Commonly used materials: Power tool housing: PA6+30%GF+HB

Gears: CTQ: high strength, high toughness, dynamic balance.

Gear: PA66+30%GF+HB.

6-Daily necessities structural parts CTQ: high strength, high surface, high toughness.

Commonly used materials:

Spatula: food grade PA66+30%GF;

Office chair legs: PA6+30%GF+HB;

Exhaust duct: PA6+30%GF+HB;

Water meter shell: PA66+30%GF+HB.

7-Industrial supplies structural parts CTQ: high strength, high toughness, high and low temperature resistance.

Electric valve: PA66+30%GF+HB.

8-Bonnet cover CTQ: good surface, low shrinkage, high creep resistance, heat resistance.

Commonly used materials: PA66+GF30.

9-Water cooling system CTQ: good surface, high strength, low shrinkage, hydrolysis resistance, heat aging resistance.

Commonly used materials: PA66 + GF30 + hydrolysis resistance.

Third, PA66+30%GF shrinkage.

PA66 +30% GF in the actual injection molding process shrinkage rate according to the injection molding process and product application there will be significant differences, especially when encountered in the product average glue bit too thick, too thin (0.5 or less) and product dimensions are large to pay special attention.

1.PA66 + 30% GF commonly used plastic shrinkage (%)

Polyamide 66 reinforced (PA66+30%GF): 0.2-0.8.

2-PA66+30%GF shrinkage rate:

The following is a typical PA66+30%GF shrinkage rate introduction:

Plastic name: PA66+30%GF.

Actual molding shrinkage rate: 0.005.

Molding product type: office chair legs.

Plastic Name: PA+30%GF.

Actual mold shrinkage: 0.0035.

Open mold product type: auto parts (reflector).

Related Keywords

Related Keywords