NYLATRON® MC 901 CNC part

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, HongKong

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 50000 pcs per day |

|---|---|

| Supply Ability: | Enough |

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Certificate: | SGS RoHS Reach ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,HongKong |

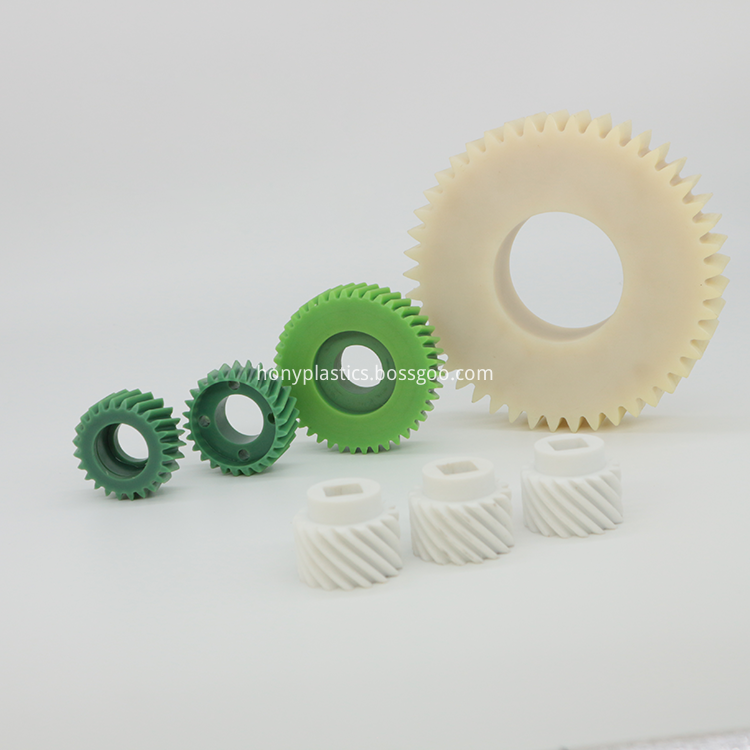

NYLATRON®MC901 custom spur gear Blue Nylon MC901 Material Spur Gear Without Hub Module:M0.5-M10 Material: C45/Stainless steel/Brass/Plastic/POM/Nylon Pressure angle:20 degree Precision grade:DIN6/DIN7/DIN8/DIN9/DIN10 Machining process:Hobbing, Milling, Drilling, Shaving, Grinding Heat treatment:Hardening and Tempering, High Frequency Quenching,Carburizing etc . Surface treatment:Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating

Our advantage

Plastic gears material:Nylon;POM;UHMWPE

We manufacture plastic parts according to customers' designs;

We can offer material certification,test report and relate surface-treatment report;

Platic gears process:CNC machining,Milling,Drilling,Turning;

Products shown on the website are OEM;

Customized designs are welcome;

Plastic gears OEM/ODM orders are welcome;

Our Service

1)We are a manufacturer integrating industry and trade.

2)We foceus on processing plastic products for 13 years.

3)We are located in guangzhou huangpu,near guangzhou wuchong port.

4)Flexible delivery,Super quality,Factory price.

5)OEM Service: customize color,size,material.

6)MOQ:1pc.

Processing equipment:

CNC machinery center,engraving machine,Cnc lathe and other equipment processing services.

Processing materials:

PTFE,POM,Nylon,UHMWPE,PEEK,HDPE,PU,PTE.ect(only plastic material)

Commitment:

if the parts cannot be used because of the processing problems,we will be responsible for free repair or reprocessing,and bear the

round-trip freight.

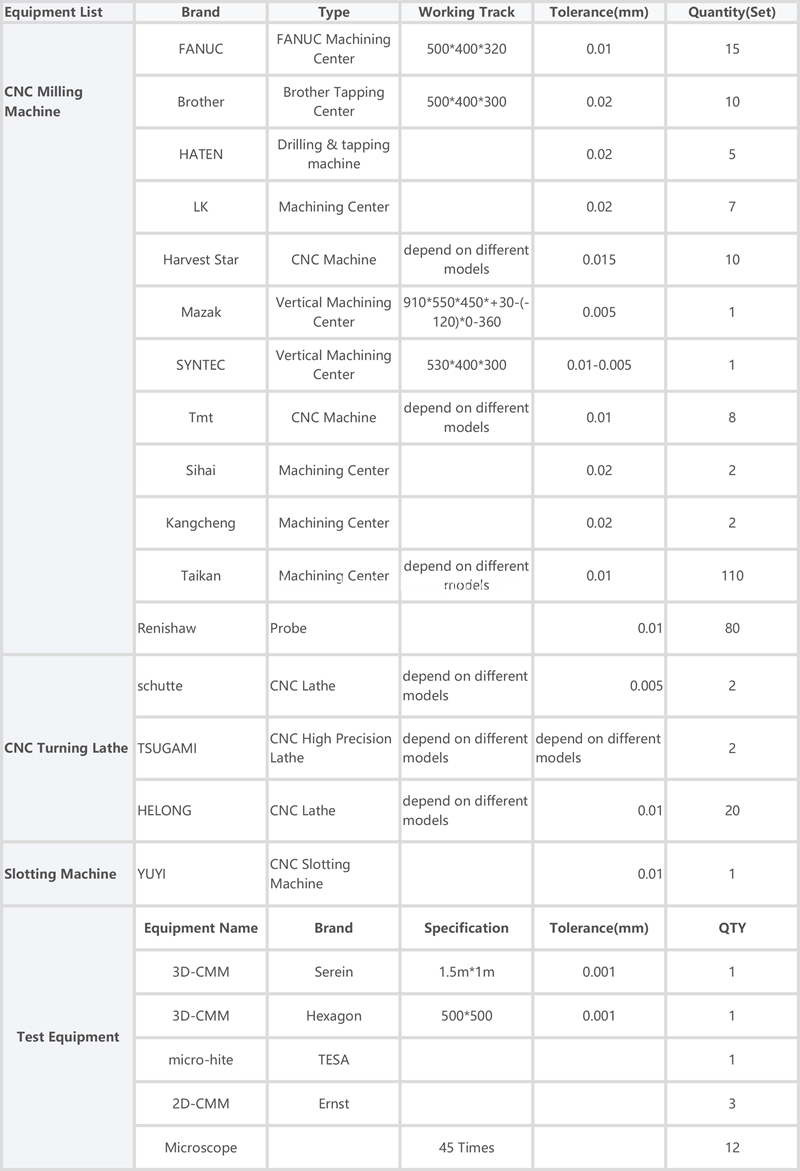

Our machine list

CNC Machined processing

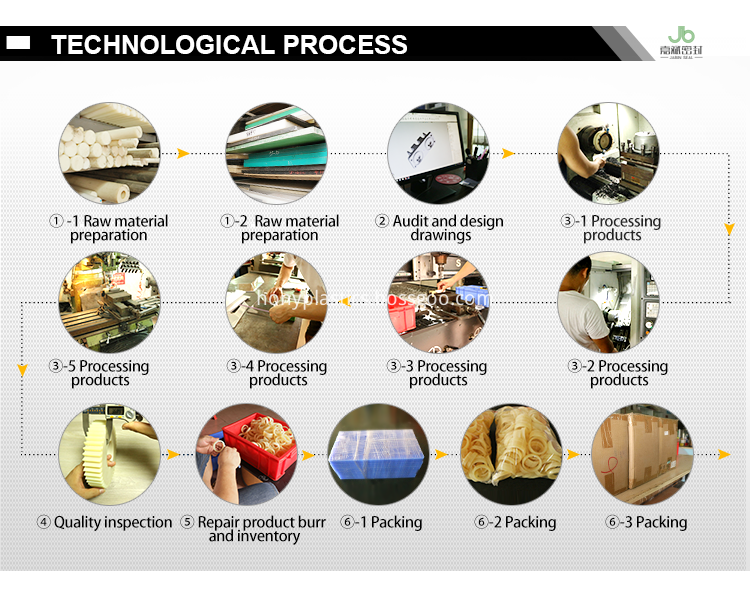

Technological process:

Step.01: Raw material preparation

Step.02: Audit and design drawings

Step.03: Processing products

Step.04: Quality inspection

Step.05: Repair product burr and inventory

Step.06: Packing

Service process:

Step.01: The format of the drawing can be identified

Step.02: Response quotation and delivery time.

Step.03: Confirm the information and pay the order.

Step.04: Complete the order and wait for delivey.

Drawing format:

2D:JPG, PDF, DWG, DXF, EXB

3D:SLDPRT,PRT, CATPART STP, STEP, IGS, X_T

CNC Service

Our machine

Our partner

Package

Related Keywords