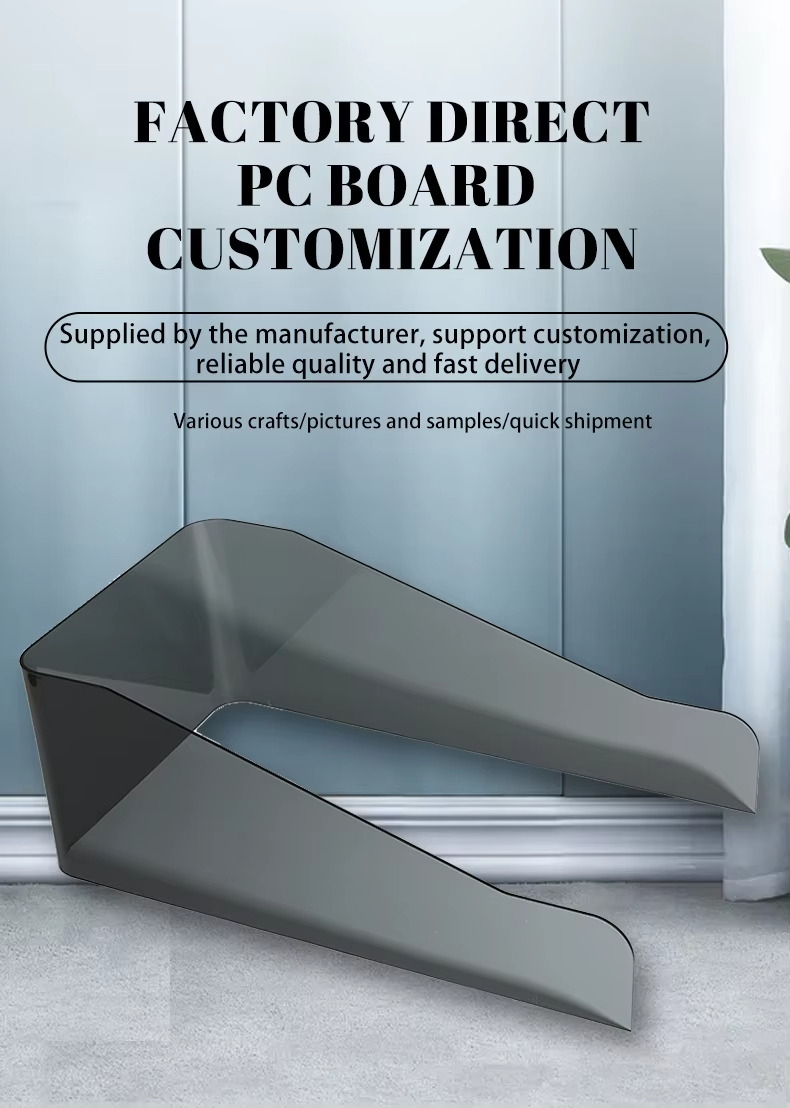

Transparent Black Smoky Anti Uv Polycarbonate PC Sheet

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Hongkong, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

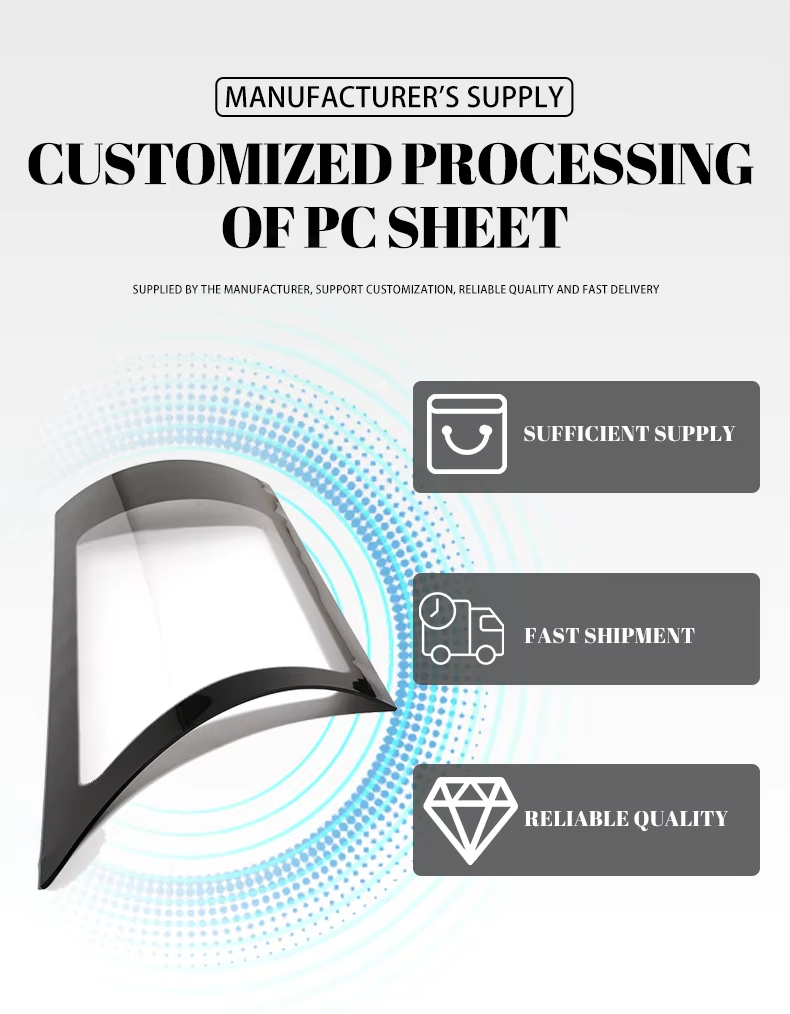

| Supply Ability: | 1000 |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Hongkong,Guangzhou |

Product Description

Product Description

PC sheets, also known as polycarbonate sheets, are resistant to weak acids. They are primarily composed of polycarbonate and are manufactured using co-extrusion technology (CO-EXTRUSION). PC sheets are resistant to neutral oils but are not resistant to strong acids, harsh environments, or alkalis. A UV coating must be applied for these conditions. They feature high transparency, lightweight, impact resistance, sound insulation, heat insulation, flame retardancy, and resistance to aging. These are high-tech, environmentally friendly plastic sheets with exceptional comprehensive performance, widely adopted as plastic building materials internationally. They offer advantages unmatched by other building decoration materials such as glass or acrylic.

Classification

PC sheets are generally categorized into sunboards and impact-resistant sheets, with colors typically available in transparent or black.

Properties

(1) Light transmission: PC sheets can achieve a light transmission rate of up to 89%, comparable to glass. UV-coated sheets do not yellow, fog, or lose transparency when exposed to sunlight. After ten years, light transmission loss is only 6%, while PVC loses 15%-20% and fiberglass loses 12%-20%.

(2) Impact resistance: The impact strength is 250-300 times that of ordinary glass, 30 times that of acrylic sheets of the same thickness, and 2-20 times that of tempered glass. Even when dropped from a height of two meters with a 3kg hammer, there are no cracks. It is known as “unbreakable glass” and “sound steel.”

(3) UV protection: One side of the PC sheet is coated with an anti-UV (UV) layer, while the other side has anti-condensation treatment, combining UV protection, heat insulation, and anti-condensation functions. It can block UV rays from passing through, making it suitable for protecting valuable artworks and exhibits from UV damage.

(4) Lightweight: With a density half that of glass, it reduces costs associated with transportation, handling, installation, and support frameworks.

(5) Flame-retardant: According to national standard GB50222-95, PC sheets are classified as Class B1 flame-retardant. The self-ignition temperature of PC sheets is 580°C, and they self-extinguish upon removal from the flame. They do not emit toxic gases when burning and do not contribute to the spread of fire.

(6) Flexibility: They can be cold-bent on-site according to design drawings to form arched, semi-circular roofs, and windows. The minimum bending radius is 175 times the thickness of the sheet, and they can also be heat-bent.

(7) Sound insulation: PC sheets offer significant sound insulation, with better acoustic insulation than glass or acrylic sheets of the same thickness. Under the same thickness conditions, the sound insulation of PC sheets is 3-4 dB higher than that of glass. Internationally, PC sheets are the preferred material for highway sound barriers.

(8) Energy efficiency: PC sheets provide cooling in summer and insulation in winter. They have a lower thermal conductivity (K value) than ordinary glass and other plastics, with insulation performance 7%-25% higher than equivalent glass. PC sheets achieve up to 49% insulation, significantly reducing heat loss. They are an environmentally friendly material suitable for buildings with heating systems.

(9) Temperature Adaptability: PC panels do not become brittle at -100°C and do not soften at 135°C. In harsh environments, their mechanical and physical properties remain unchanged.

Applications

Unique decorations and pavilions in gardens and amusement parks;

Interior and exterior decorations of commercial buildings, and curtain walls of modern urban buildings;

Transparent containers for aviation, motorcycle windshields, aircraft, trains, ships, cars, motorboats, submarines, and glass shields for military and police use;

Telephone booths, advertising signs, lightbox advertisements, and exhibition displays;

Instrument panels, high/low-voltage switchgear panels, and military industrial applications;

High-end interior decoration materials such as walls, ceilings, and screens;

Soundproof barriers for highways and urban elevated roads;

Agricultural greenhouses and livestock sheds;

Roofs for modern ecological restaurants.

Product name

Acrylic sheet /PC custom

Product size

Customize according to demand

Product color

Transparent black

Material

PC

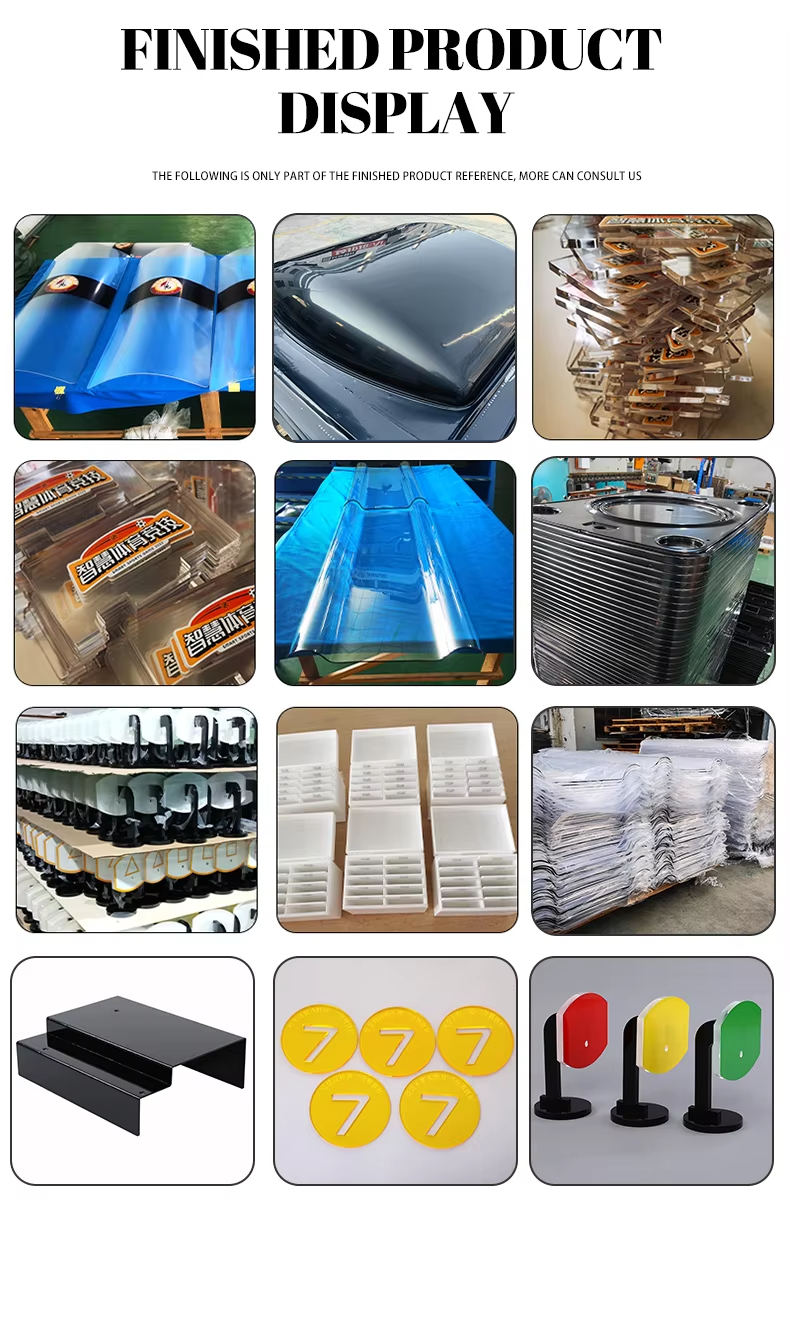

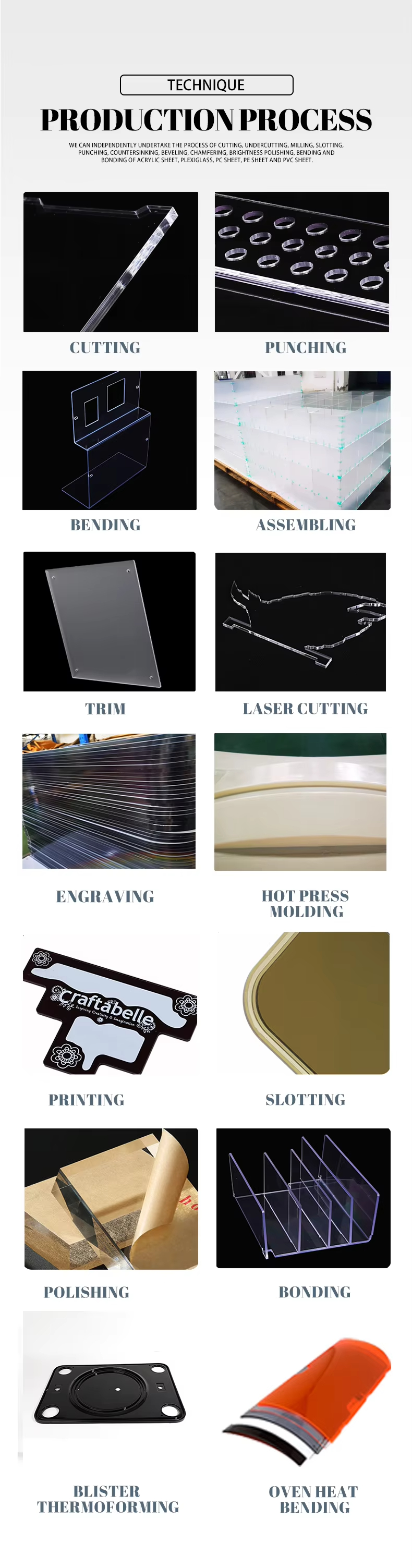

Processing technology

Three-dimensional machining,Surface machining

Three-dimensional machining

Engraving, groove milling, hot and cold bending, printing, forming, polishing, bonding, assembly

Surface machining-PC

Engraving, groove milling, hot and cold bending, printing, forming, polishing, bonding, assembly

Surface machining-Acrylic

Laser cutting, engraving, grooving, hot and cold bending, printing, forming, polishing, bonding, assembly

Custom

Drawing to sample/custom size, thickness

Shape appearance

Custom drawing

Related Keywords

Related Keywords