3240 Epoxy Glass Fiber Sheet

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Hongkong, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Hongkong,Guangzhou |

Product Description

Product Description

3240 epoxy board is a type of board made from electrical glass cloth impregnated with epoxy resin, then dried and hot-pressed. It is commonly referred to as an insulating board or epoxy board, and possesses excellent insulating and mechanical properties, making it widely used in the power and electrical industries.

Characteristics of 3240 Epoxy Board

Excellent Insulation Performance: 3240 epoxy board has high mechanical strength and good dielectric properties, making it suitable for use in electrical equipment insulation components.

Good Mechanical Properties: After curing, the epoxy resin board has excellent mechanical strength and electrical insulation properties, making it suitable for use as an insulating material.

Low shrinkage: During curing, the epoxy resin board has minimal shrinkage and low internal stress, which helps enhance adhesion strength and extend service life.

Dimensional stability: After curing, the epoxy resin board exhibits excellent dimensional stability and long-term performance.

Mold resistance: The cured epoxy resin board is resistant to mold, making it suitable for use in tropical and high-humidity environments.

Application areas of 3240 epoxy boards

Hydropower: Used as insulating components in hydropower projects.

Switchgear: Used as insulating components in switchgear.

Semiconductors: Used as insulating components in semiconductors.

Electrified Railways: Used as insulating components in electrified railways.

Transformers: Used as insulating components in high and low-voltage transformers.

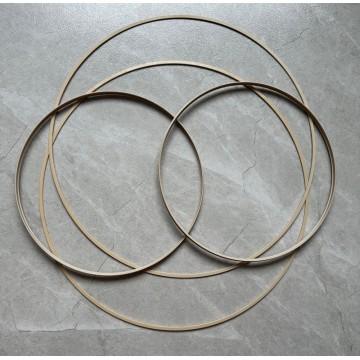

Busway: Used as insulating partitions and gaskets in busways.

Shipbuilding: Used as insulating components in shipbuilding.

Variable Frequency Drives: Used as insulating components in variable frequency drives.

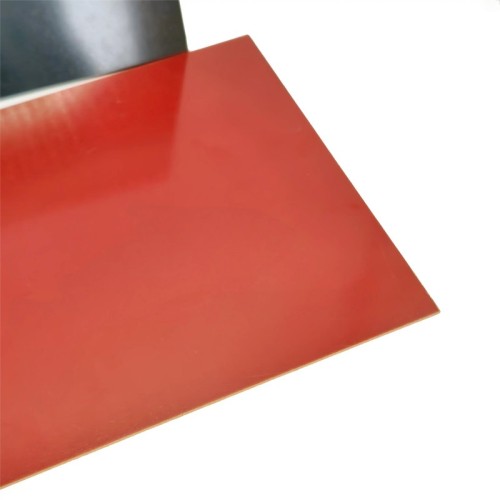

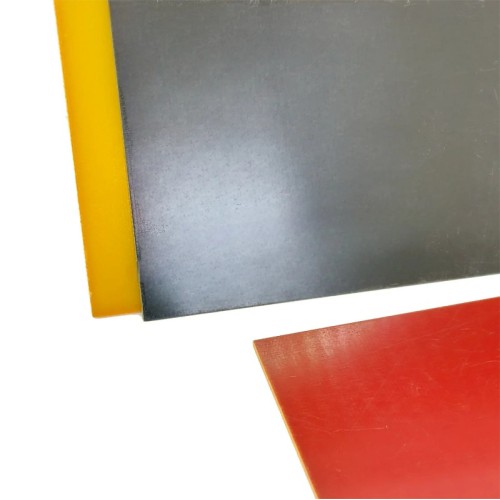

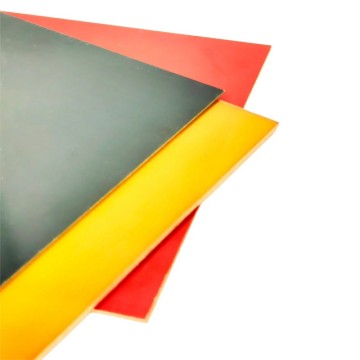

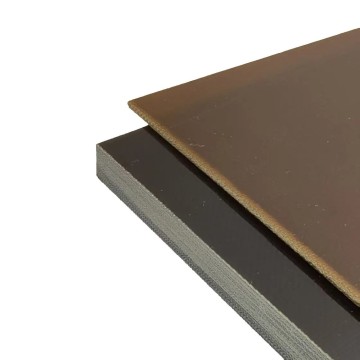

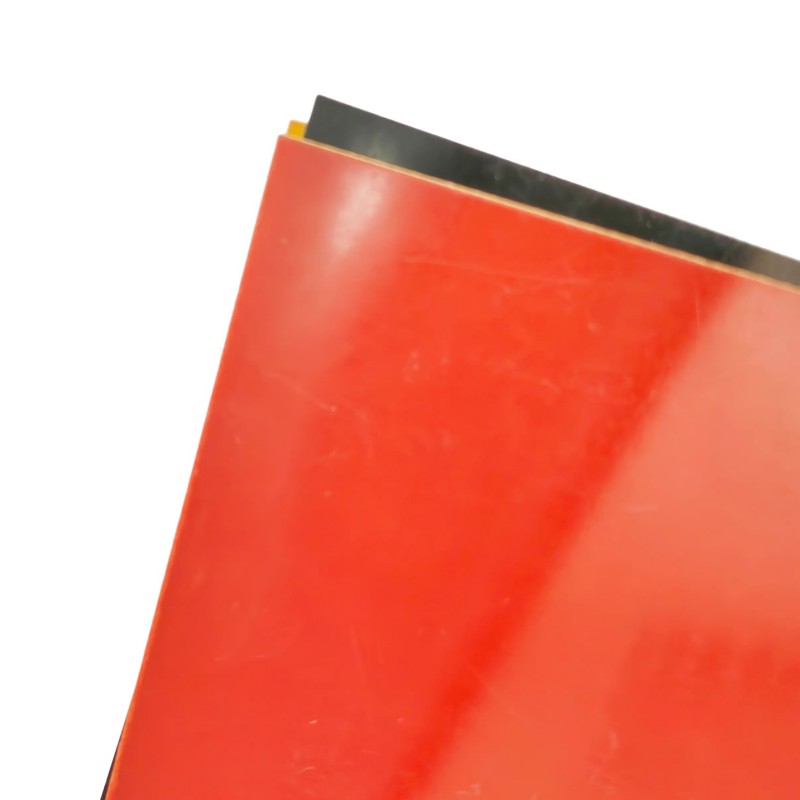

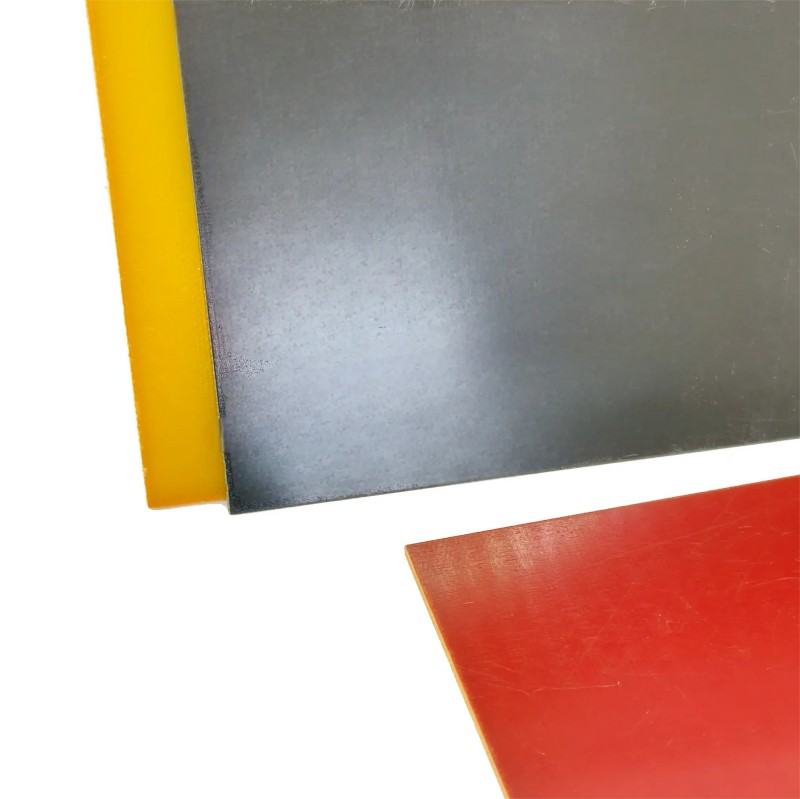

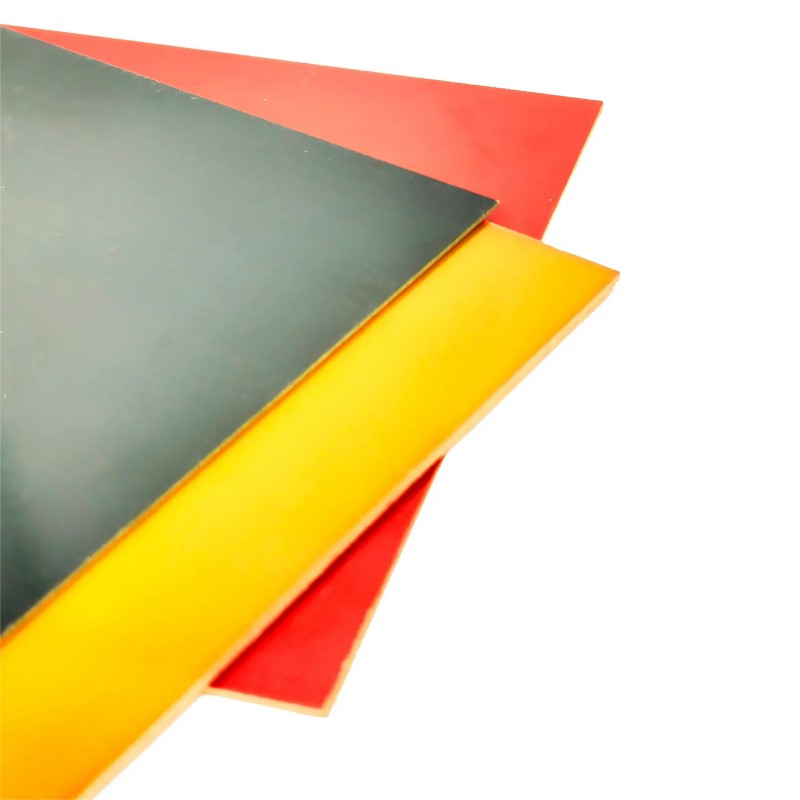

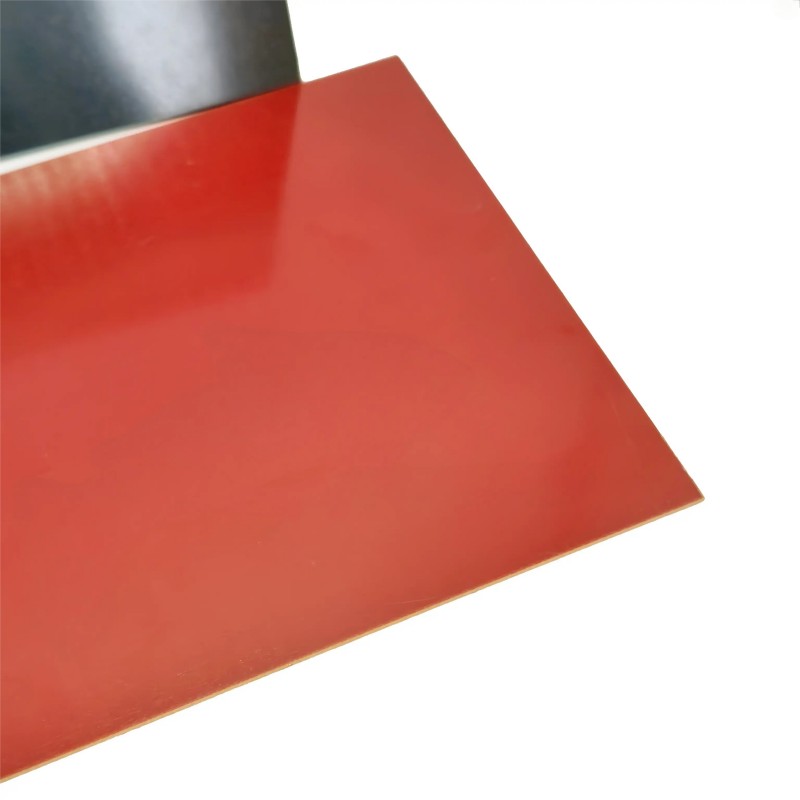

3240 Epoxy Laminate Board Surface Requirements: The surface must be smooth, free of bubbles, pits, and wrinkles. However, other defects that do not affect usability are permitted, such as scratches, indentations, stains, and minor spots. Edges must be cut neatly, and end faces must not have delamination or cracks.

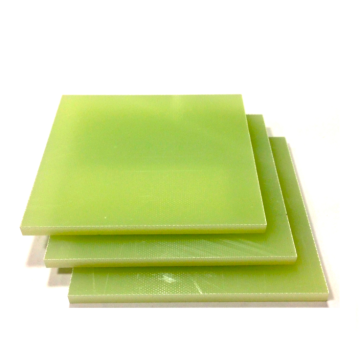

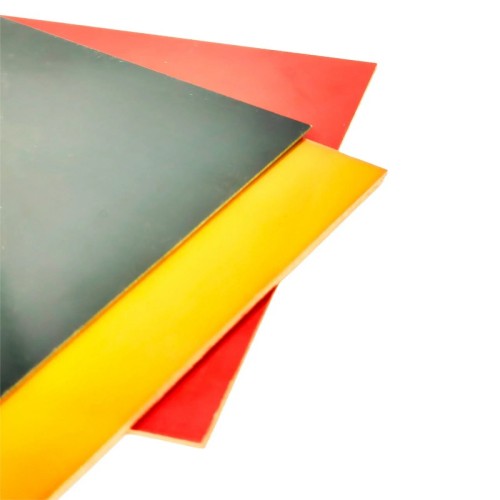

Standards: GB/T1303.1-1998 (natural color); red, green, and black are agreement standards.

Temperature rating: Class B

Color: Natural (yellow), red, green, black, etc. (colors can be added to create multiple shades)

Properties: The cured epoxy resin system exhibits excellent mechanical properties, high mechanical strength at moderate temperatures, and stable electrical performance under high humidity conditions.

Electrical Properties: The cured epoxy resin system is an excellent insulating material with high dielectric properties, resistance to surface leakage, and resistance to arcing.

Applications: Suitable for mechanical, electrical, electronic, and appliance industries. Also used for processing insulating components, manufacturing various insulating accessories, and equipment insulating structural parts.

Thickness: Typically 0.5–50 mm, but can be produced up to 50–150 mm thick plates upon request.

The reaction between epoxy resin and the curing agent occurs through direct addition reactions or the ring-opening polymerization of epoxy groups in the resin molecules, without the release of water or other volatile byproducts. Compared to unsaturated polyester resins and phenolic resins, they exhibit very low shrinkage (less than 2%) during curing.

What is the difference between 3240 boards and epoxy boards?

3240 boards and epoxy boards differ significantly in several aspects.

3240 boards are typically composite panels made primarily from wood fibers and other materials through a specific manufacturing process. They possess a certain level of strength and toughness, with a relatively hard texture capable of withstanding moderate pressure and impact forces. In terms of appearance, the surface of 3240 boards is relatively rough, may exhibit some fiber patterns, and has a more natural color. Its advantages include relatively low cost and good machinability, allowing for various processing operations such as sawing, planing, and drilling. It is suitable for manufacturing structural components or parts that do not require extremely high precision.

Epoxy boards, on the other hand, are insulating panels made primarily from epoxy resin through heating and curing processes. They offer excellent insulation properties, effectively preventing current leakage, and are suitable for applications in electrical and electronic fields. Epoxy boards have a smooth and flat surface, uniform texture, and are typically light yellow or white in color, offering high aesthetic appeal. They also have considerable strength and excellent heat resistance, corrosion resistance, and mechanical properties, maintaining good performance even in harsh environments such as high temperatures or humidity. However, epoxy boards are relatively more expensive than 3240 boards and are more difficult to process, typically requiring specialized equipment and technical expertise.

Related Keywords

Related Keywords