Fr4 Machined Parts Cnc Machining Service

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 10000 |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

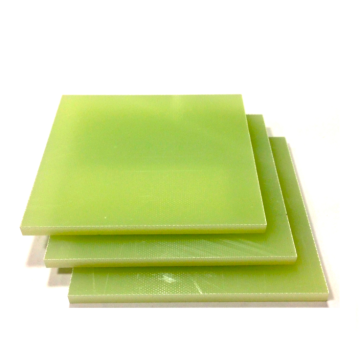

Epoxy board: a high-performance insulating material

Epoxy board, also known as epoxy resin board, insulating board or 3240 epoxy board, is refined through the close bonding of fiberglass cloth and epoxy resin, and then through a series of heated and pressurized processes. Its adhesive force is exceptionally strong.

The inherent polar hydroxyl and ether bonds in the molecular chain of the epoxy resin give it excellent adhesion to a wide range of substances. Its adhesive strength is further enhanced by its relatively low shrinkage during curing, which results in low internal stress.

Low Shrinkage

The reaction between the epoxy resin and the curing agent relies mainly on direct addition or ring-opening polymerization of the epoxy groups within the resin molecule. In this process, no water or other volatile by-products are generated, so compared with unsaturated polyester resins and phenolic resins, its shrinkage during curing is significantly reduced to less than 2%.

Excellent chemical stability.

The cured epoxy resin system exhibits excellent resistance to alkalis, acids and solvents, and can be further endowed with unique chemical stability through careful selection of epoxy resins and curing agents.

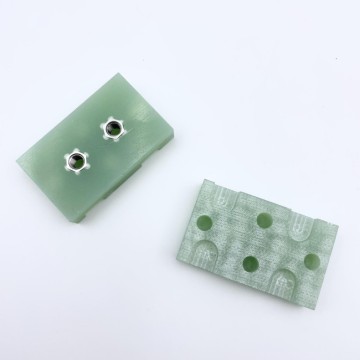

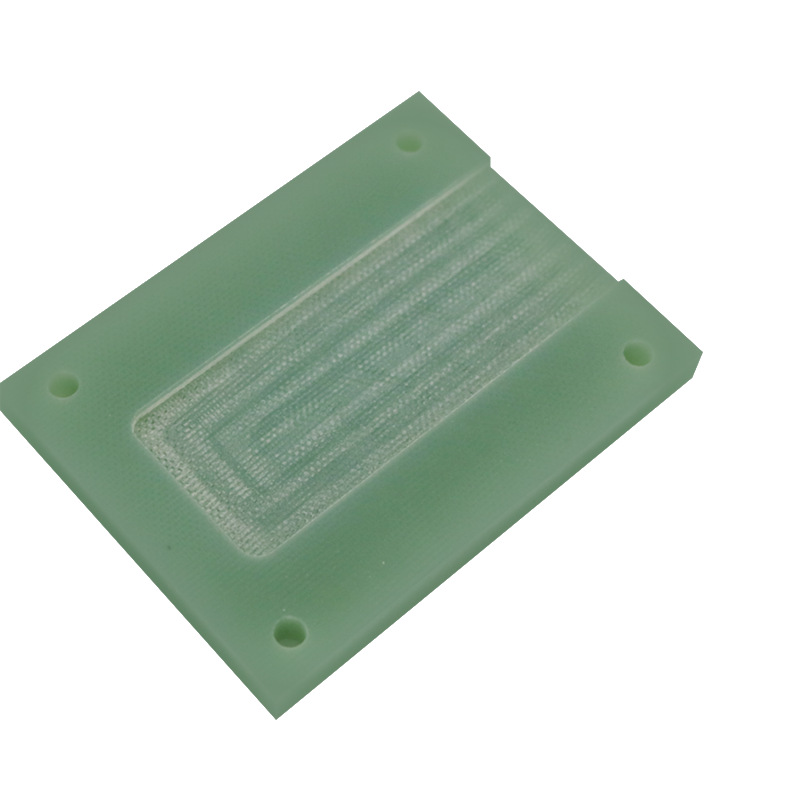

Which epoxy board process is better to use?

Epoxy board is a commonly used industrial material, widely used in electronic equipment, aerospace, shipbuilding and other industries. When processing epoxy board, choosing the right process plays a crucial role in the quality and performance of the product. At present, the common epoxy plate processing process mainly includes mechanical processing, chemical processing and thermal processing and other methods. So, which processing process is better? The following will be analyzed in detail.

First of all, machining is a common epoxy plate processing method, including milling, drilling, turning and other operations. Machining is widely used because of its simple operation, low cost and low environmental requirements during operation. Machining can realize high-precision processing of epoxy boards, can meet the requirements of product size, shape and other requirements, high processing efficiency, suitable for mass production. Moreover, the operation of machining is relatively easy to control, and the operators only need to have a certain level of technology to operate!

Secondly, chemical processing is another common epoxy plate processing methods, including corrosion, electrolysis, chemical cleaning and other processes. Chemical processing can realize the fine processing on the surface of epoxy board, the chemical properties of epoxy board has certain improvement effect, some of the chemical processing methods can improve the corrosion resistance and wear resistance of epoxy board. Chemical processing can reduce the impact on the hardness of the epoxy plate, and also can remove the surface oxidized layer and improve the surface finish of the epoxy plate. However, chemical processing has higher requirements on the environment, and requires strict control of the concentration of chemicals, temperature and other factors in the processing process, and the operation process is relatively complicated.

Again, thermal processing is a special epoxy plate processing method, mainly including hot pressing, hot pressing glue and other operations. Thermal processing can increase the strength and toughness of the epoxy board, improve the performance of the product, and is suitable for occasions where the strength of the product is required to be high. Thermal processing can realize the adjustment of the shape and size of the epoxy board, so that the product is closer to the design requirements. However, thermal processing operation needs to control the heating temperature, pressure and other parameters, the selection of epoxy plate materials also has certain requirements, the operation process is more complex.

In summary, different epoxy plate processing methods have their own advantages and disadvantages. Mechanical processing applies to the product shape, size requirements of the occasion, low cost, simple operation, suitable for mass production; chemical processing applies to improve the chemical properties of the material, can improve the surface properties of the product, but the operation is relatively complex; thermal processing applies to improve the product strength and toughness of the occasion, but the operation requirements are higher. Therefore, in the actual production, should be based on the specific requirements of the product to choose the appropriate epoxy plate processing methods, in order to obtain better processing results.

Related Keywords

Related Keywords