Acrylic Plastic CNC Machined Parts

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 1000 |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

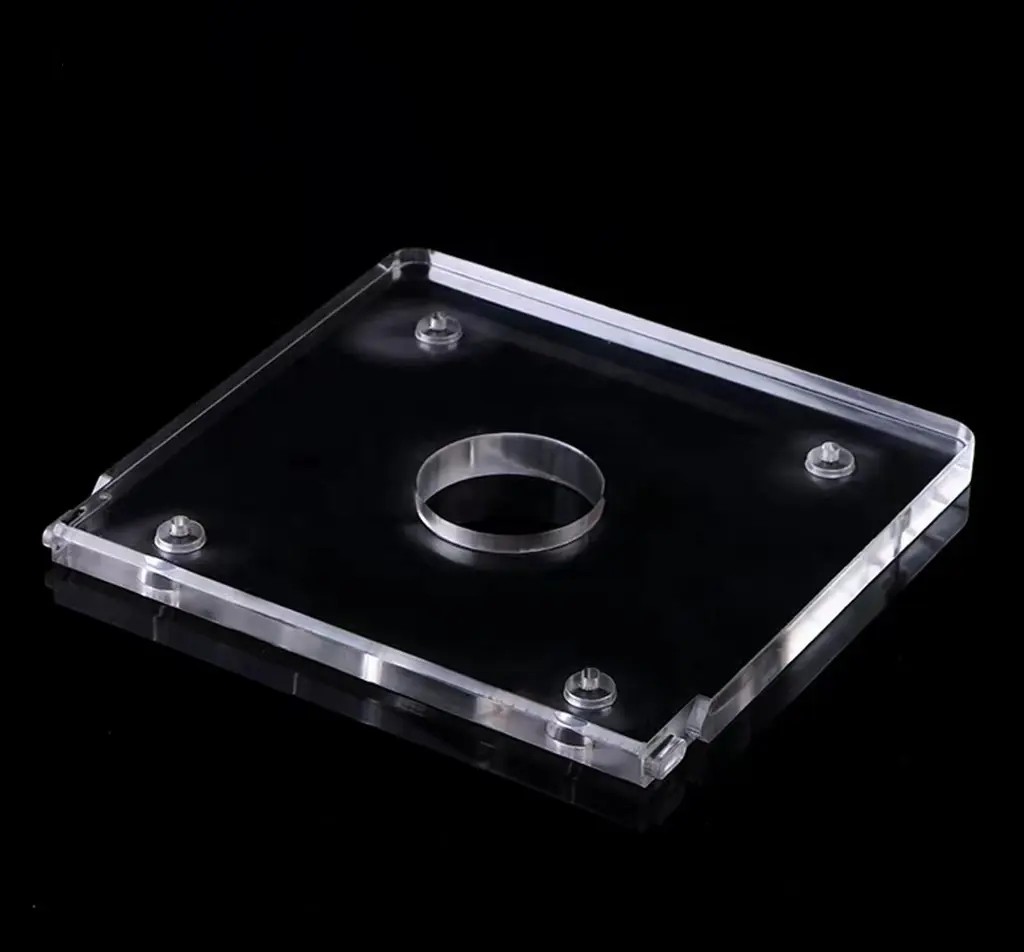

In the wave of modern manufacturing, CNC machining technology has become the machining means of choice in many fields due to its high precision and efficiency. Today, let's delve into how CNC machining accomplishes the manufacturing of transparent acrylic parts and gives them the beauty of crystal clarity.

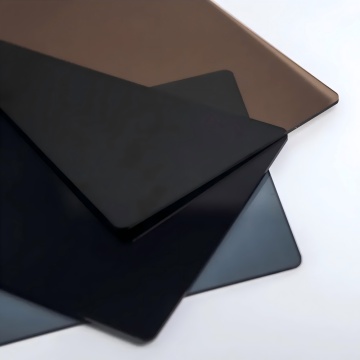

Characteristics of Transparent Acrylic

Transparent acrylic, as a high-performance plastic material, has a high degree of transparency, light weight, good processing performance and other characteristics. Its good transparency makes acrylic products visually more attractive, at the same time, good processing performance also provides a wide space for CNC machining.

CNC machining process of transparent acrylic parts

Design and Programming: First of all, the need for three-dimensional modeling according to the needs of the product, and through the CAM (Computer Aided Manufacturing) software for programming, to generate CNC machine tools can recognize the processing instructions.

Material Preparation: The transparent acrylic sheet is cut according to the design requirements and the raw material to be processed is prepared.

CNC machine processing: the prepared acrylic material is placed on the CNC machine, according to the programming instructions for processing. In the processing process, the machine tool will be in accordance with the preset path of high-speed rotation and movement, so as to achieve the precise cutting and shaping of acrylic materials.

Advantages of CNC machining transparent acrylic parts

High precision: CNC machining can achieve micron-level machining accuracy, ensuring that the size and shape of the parts meet the design requirements.

High efficiency: Compared with traditional manual machining methods, CNC machining can significantly increase productivity and shorten the production cycle.

Strong customizability: Through programming and adjusting machining parameters, CNC machining can easily achieve different shapes and sizes of parts, to meet the individual needs of customers.

Low cost: in the case of mass production, CNC machining can significantly reduce production costs and improve the competitiveness of enterprises.

Application Prospects

CNC machined transparent acrylic parts have a wide range of application prospects in electronic products, automotive, aerospace and other fields. For example, in electronic products, transparent acrylic parts can be used as shells, buttons and other components to enhance the overall aesthetics of the product and user experience. In the automotive and aerospace fields, transparent acrylic parts can be used for the production of windows, instrument panels and other components to meet the demand for lightweight, high transparency.

In summary, CNC machining technology provides strong support for the manufacture of transparent acrylic parts with its high precision, high efficiency, strong customizability and other characteristics. With the continuous development and progress of the manufacturing industry, CNC machined transparent acrylic parts will show its unique charm and value in more fields.

Acrylic is a machinable, hand-processed materials.

First, machining

Machining is a method of processing complex acrylic products into the required shape and size. The biggest advantage of machining acrylic is high precision and speed. Machining usually use numerical control processing (CNC) technology, can be pre-programmed to accurately locate the position of the part, so that the machine at high speed processing and cutting. Common equipment used to machine acrylic includes CNC engraving machines, laser cutting machines, and CNC milling machines. However, using machined acrylic requires a significant investment in purchasing and maintaining these machines and equipment, which may not be a good fit for small-scale manufacturers.

Second, hand processing

Hand processing compared to machining, the cost is low, the work is relatively flexible and convenient, and suitable for small-scale manufacturers. Hand processing can be carried out by a variety of hand tools, such as saws, fire burners and other tools. Hand-processed acrylic products manufactured by hand, although there may be differences in precision, but the manufacturing convenience, suitable for small-scale production and personalized customization.

Third, machining or hand processing?

For beginners, it is recommended to use hand-processed acrylic to improve their knowledge and skills in the use of acrylic. While some large-scale manufacturers should choose machining technology to improve production and quality.

It is important to note that before machining or hand processing acrylic, you need to choose the right material to avoid damage to the parts due to insufficient strength of the material, and the residue and bubbles produced by improper use can have a very big impact on the final result. Before using any tool, please understand the correct tool operation method and safety measures to avoid accidental damage during operation.

Related Keywords

Related Keywords