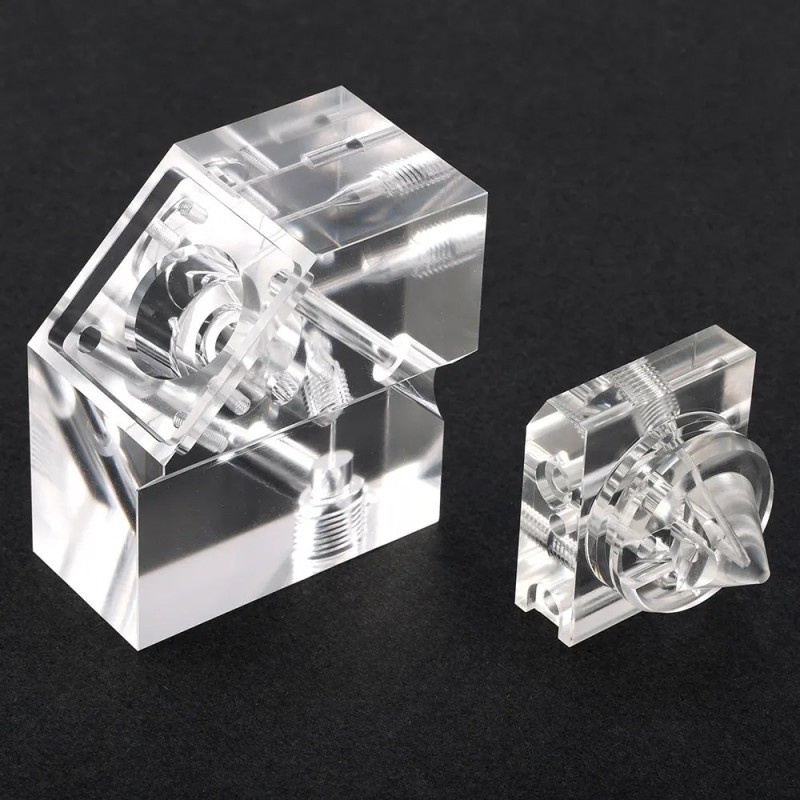

CNC Turning Polished PMMA fabrication parts

- Min. Order:

- 1

- Min. Order:

- 1

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Hongkong

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Supply Ability: | 100 |

|---|---|

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Hongkong |

Product Description

Product Description

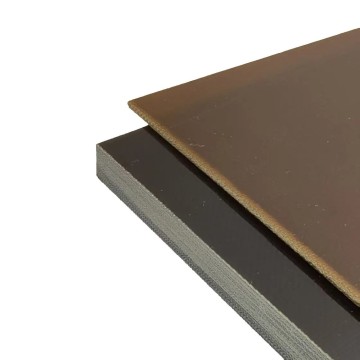

Acrylic, also known as PMMA or Plexiglas, from the English acrylic (acrylic plastic), the chemical name is polymethyl methacrylate, is an important plastic polymer material developed earlier, with good transparency, chemical stability and weather resistance. It is easy to color, easy to process, beautiful appearance, and has a wide range of applications in the construction industry. Plexiglass products can usually be categorized into cast sheets, extruded sheets and molded plastics.

Acrylic products are acrylic panels, acrylic plastic particles, acrylic light boxes, signs, acrylic bathtubs, acrylic artificial marble, acrylic resin, acrylic (latex) paint, acrylic adhesive and other products, a wide variety.

People commonly seen acrylic products are made of acrylic granules, sheets or resins and other raw materials through a variety of different processing methods, and with a variety of different materials and functions of the spare parts to be assembled from the acrylic products. As for the general often heard of acrylic fiber, acrylic cotton, acrylic yarn, acrylic nylon, etc., refers to the acrylic polymerization of man-made fibers, and acrylic products are not related.

Among them, people often say acrylic sheet is Polymeric Methyl Methacrylate (PMMA) sheet, it is by the “methyl methacrylate monomer Methyl Methacrylate (MMA)” polymerization. It is made by polymerizing “Methyl Methacrylate Monomer (MMA)” or by extruding acrylic pellets through an extruder. Previously known as Plexiglas. Acrylic is derived from the English acrylic, meaning PMMA sheet made from the organic compound MMA, which is as transparent and translucent as glass. Derived from all transparent plastics such as PS, PC, etc. or made of poor quality recycled MMA sheet are collectively referred to as plexiglass. In order to differentiate, the PMMA sheet made of high quality pure MMA is named acrylic sheet, so as to differentiate it from the general Plexiglas sheet.

Performance Characteristics

1. With crystal-like transparency, light transmittance of more than 92%, soft light, visual clarity, with dye coloring of acrylic and have a very good color effect.

2. Acrylic sheet has excellent weather resistance, high surface hardness and surface gloss, and good high temperature performance.

3. Acrylic sheet has good processing performance, both thermoforming and mechanical processing can be used.

4. Transparent acrylic sheet has comparable light transmittance to glass, but only half the density of glass. In addition, it is not as fragile as glass, and even if it is damaged, it will not form sharp fragments like glass.

5. The wear resistance of acrylic sheet is close to aluminum, good stability and resistance to a variety of chemical corrosion.

6. Acrylic sheet has good printability and spraying, using the appropriate printing and spraying process, you can give acrylic products the ideal surface decorative effect.

7. Flame resistance: non-spontaneous combustion but flammable, not self-extinguishing.

Characteristics

1. Hardness

Hardness is one of the parameters that best reflects the production process and technology of cast acrylic sheet, and is an important part of quality control. Hardness can reflect the raw material PMMA purity, sheet weathering and high temperature resistance. Hardness directly affects whether the sheet will shrink and bend and deform, whether the surface will chafe when processing, etc.. Hardness is one of the hardness indicators to judge the quality of acrylic sheet.

2. Thickness (acrylic tolerance)

Acrylic sheet thickness there is an acrylic tolerance, so the control of acrylic tolerance is an important embodiment of quality management and production technology. The production of acrylic have an international standard ISO7823.

Tolerance requirements for cast sheet: Tolerance = ± (0.4 + 0.1 x thickness)

Tolerance requirements for extruded sheets: Tolerance = < 3 mm thickness: ± 10 % > 3 mm thickness: ± 5 %.

3.Transparency/Whiteness

Strict selection of raw materials, advanced formula follow-up and modern production processes ensure excellent transparency and pure whiteness of the sheets. Flame-polished and crystal clear.

Properties

Mechanical properties

Poly(methyl methacrylate) has good comprehensive mechanical properties, in the forefront of general-purpose plastics, tensile, bending, compression and other strengths are higher than polyolefins, but also higher than polystyrene, PVC, etc., the impact toughness is poorer, but also slightly better than polystyrene. Cast the body of the polymerization of polymerized polymethyl methacrylate sheet (such as aviation with plexiglass sheet) tensile, bending, compression and other mechanical properties of some higher, can reach the level of polyamide, polycarbonate and other engineering plastics.

In general, the tensile strength of polymethyl methacrylate can reach the level of 50-77MPa, bending strength can reach 90-130MPa, the upper limit of these performance data has reached or even exceeded some engineering plastics. Its elongation at break is only 2% -3%, so the mechanical properties of the characteristics of the plastic is basically hard and brittle, and notch sensitivity, easy to crack under stress, but the fracture fracture is not as sharp and uneven as the polystyrene and ordinary inorganic glass. 40 ℃ is a secondary transition temperature, equivalent to the side of the methyl group began to move the temperature, more than 40 ℃, the material's toughness, ductility has been improved. The surface hardness of polymethylmethacrylate is low and easily scratched.

The strength of polymethylmethacrylate is related to the time of stress application, and the strength decreases with increasing time of application. The mechanical properties of polymethylmethacrylate (oriented plexiglass) after tensile orientation are significantly improved, and notch sensitivity is also improved.

The heat resistance of poly(methyl methacrylate) is not high, although its glass transition temperature reaches 104℃, but the maximum continuous use temperature changes with different working conditions between 65℃-95℃, the heat distortion temperature is about 96℃ (1.18MPa), and the Vicat softening point is about 113℃. Heat resistance can be improved by copolymerizing the monomer with propylene methacrylate or bis ester-based ethylene glycol acrylate. The cold resistance of polymethyl methacrylate is also poor, with a brittleness temperature of about 9.2°C. Thermal stability of poly(methyl methacrylate) belongs to the medium, better than polyvinyl chloride and polyformaldehyde, but not as good as polyolefins and polystyrene, thermal decomposition temperature is slightly higher than 270 ° C, its flow temperature of about 160 ° C, so there is still a wide range of melt processing temperature.

Thermal conductivity and specific heat capacity of poly(methyl methacrylate) are medium level in plastics, respectively 0.19W/M.K and 1464J/Kg.K.

Electrical Properties

The electrical properties of poly(methyl methacrylate) are not as good as those of non-polar plastics such as polyolefins and polystyrene due to the presence of a polar methyl ester group in the side position of the main chain. The polarity of the methyl ester group is not too large, and polymethyl methacrylate still has good dielectric and electrical insulation properties. It is worth pointing out that polymethyl methacrylate and even the entire acrylic plastics, have excellent arc resistance, under the action of the arc, the surface will not produce carbonized conductive pathway and arc trail phenomenon. 20 ℃ is a secondary transition temperature, corresponding to the side of the methyl ester group began to move the temperature, below 20 ℃, the side of the methyl ester group in the freezing state, the material's electrical properties than in the 20 ℃ or more when it will be improved. Solvent Resistance

Solvent resistance

Poly(methyl methacrylate) is resistant to dilute inorganic acids, but concentrated inorganic acids can make it erode, alkali resistance, but warm sodium hydroxide, potassium hydroxide can make it erode, salt and grease resistance, aliphatic hydrocarbons resistance, insoluble in water, methanol, glycerol, etc., but it can absorb alcohols dissolution and stress cracking, intolerance of ketones, chlorinated hydrocarbons and aromatic hydrocarbons. Its solubility parameter is about 18.8(J/CM3)1/2 , and it can be dissolved in many chlorinated hydrocarbons and aromatic hydrocarbons, such as ethylene dichloride, trichloroethylene, chloroform, toluene and so on, and ethylene vinyl acetate and acetone can also make it dissolved.

Polymethyl methacrylate has good resistance to gases such as ozone and sulfur dioxide.

Weather Resistance

Poly(methyl methacrylate) has excellent resistance to atmospheric aging, its specimens after 4 years of natural aging test, weight change, tensile strength, light transmission rate slightly decreased, color slightly yellowish, silver grain resistance decreased more obviously, impact strength also slightly improved, other physical properties are almost unchanged.

Combustibility

Poly(methyl methacrylate) is easy to burn, the ultimate oxygen index is only 17.3.

Related Keywords

Related Keywords