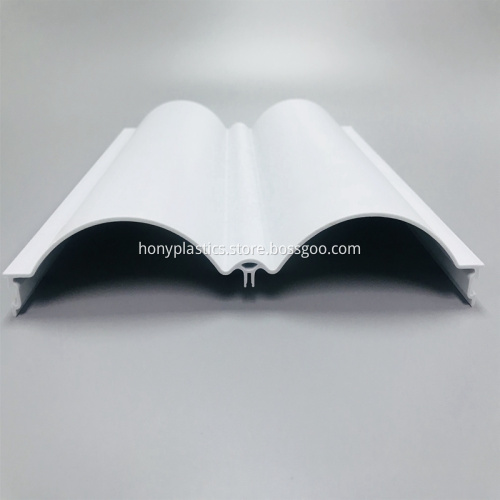

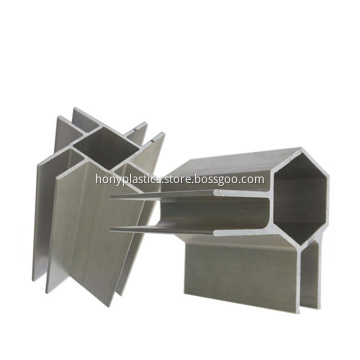

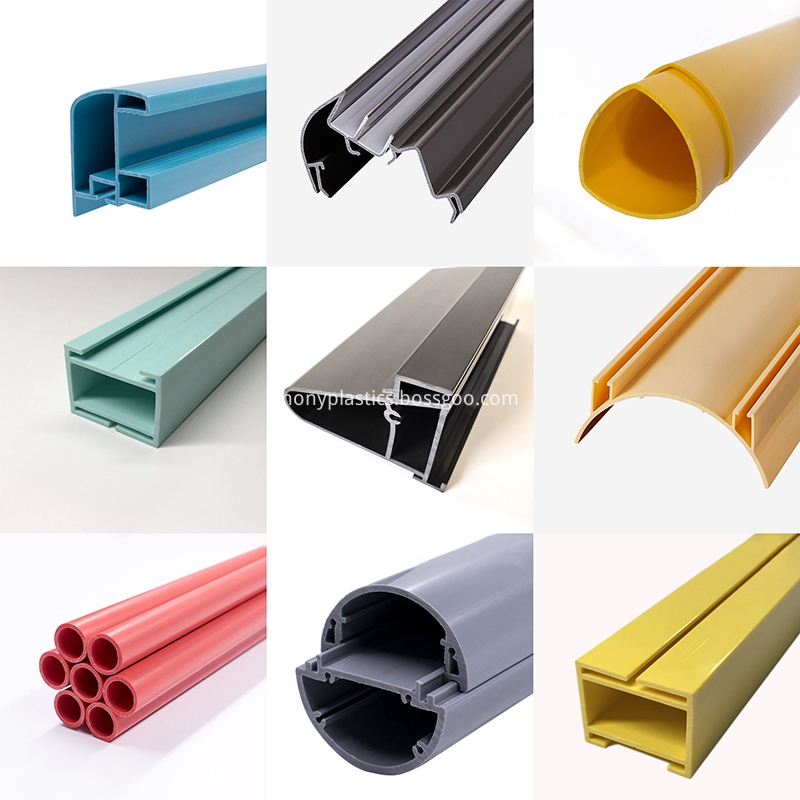

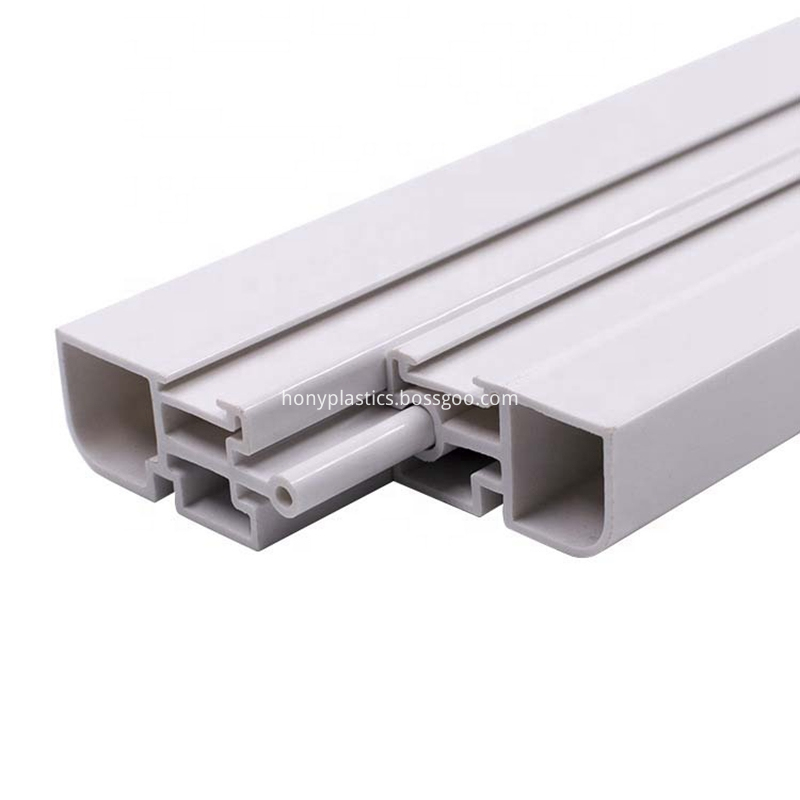

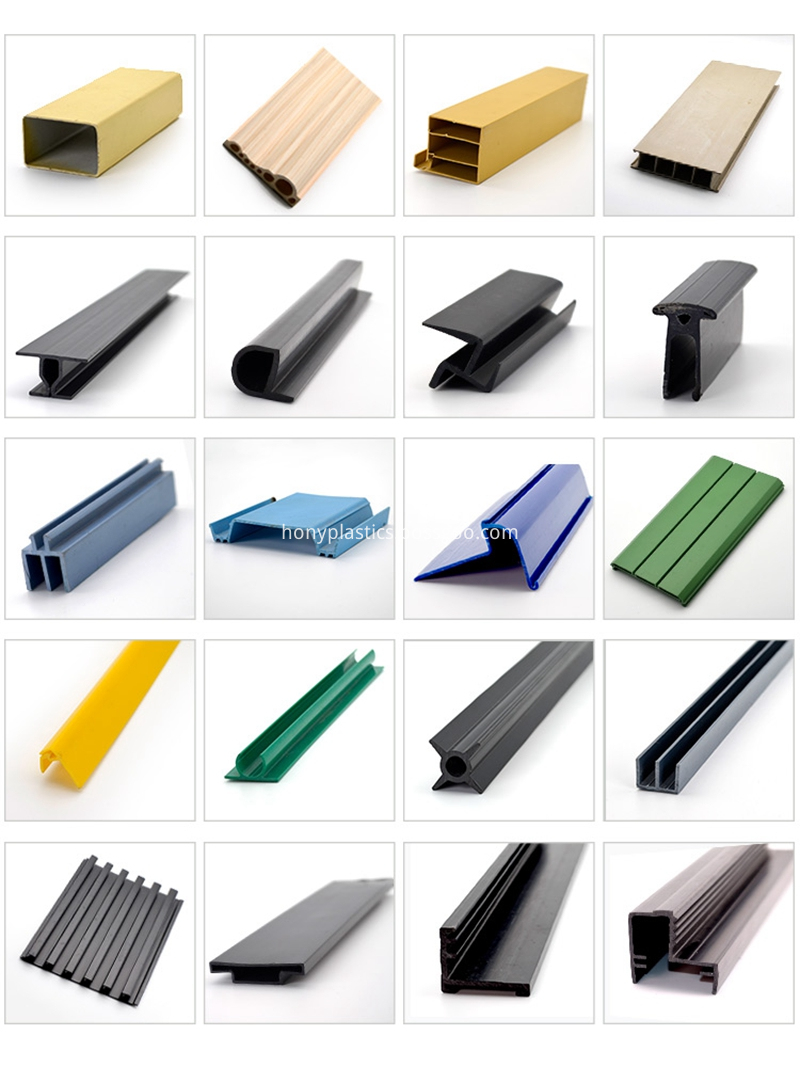

ABS extrusion profile for led light housing

-

$2.901-99 Meter

-

$2.80100-999 Meter

-

$2.70≥1000 Meter

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou , Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | Enough |

|---|---|

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Certificate: | ISO SGS REACH ROHS |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou ,Hongkong |

HONYPRO®shapes Led flexible abs extrusion plastic profile,Big ABS extrusion profile, ABS extruded profile, ABS cover for vending machines,good impact strength along with good rigidity, ABS is relatively lightweight,Custom-made tooling and sizes profiles are available,Use ABS as raw material, extruded, irregularly shaped profiles,ABS resin is one of the five major synthetic resins. It has excellent impact resistance, heat resistance, low temperature resistance, chemical resistance, and electrical properties. It also has the characteristics of easy processing, stable product dimensions, and good surface gloss. It is easy to paint , Coloring, it can also be used for secondary processing such as surface metal spraying, electroplating, welding, hot pressing and bonding. It is widely used in machinery, automobiles, electronic appliances, instrumentation, textiles and construction and other industrial fields. A wide range of engineering thermoplastics. Acrylonitrile-butadiene-styrene copolymer is a terpolymer composed of acrylonitrile, butadiene and styrene. The English name is acrylonitrile–butadiene–styrene copolymer, or ABS for short. ABS is usually a light yellow or milky white granular amorphous resin. ABS is one of the most widely used non-universal plastics.

Properties of ABS.

ABS is synthesized from three chemical monomers, acrylonitrile, butadiene and styrene. (Each monomer has different properties: acrylonitrile has high strength, thermal and chemical stability; butadiene has toughness and impact resistance; and styrene has easy processing, high finish and high strength.

The polymerization of the three monomers produces a terpolymer with two phases, a continuous phase of styrene-acrylonitrile and a dispersed phase of polybutadiene rubber). Morphologically, ABS is a non-crystalline material with high mechanical strength and good "tough, tough, steel" properties. ABS is an amorphous polymer, a general-purpose engineering plastic with a wide variety of uses, also known as "general-purpose plastics" (MBS is called transparent ABS), ABS is easy to absorb moisture, specific gravity of 1.05g/cm3 (slightly heavier than water), low shrinkage (0.60%), dimensional stability, and easy to mold and process.

The properties of ABS depend mainly on the ratio of the three monomers and the molecular structure in the two phases. This allows for great flexibility in product design and has resulted in hundreds of different qualities of ABS materials on the market. These different qualities offer different properties, such as medium to high impact resistance, low to high gloss and high temperature twist properties, etc. ABS materials offer superb processability, appearance, low creep and excellent dimensional stability and high impact strength.

ABS is a light yellow granular or beaded opaque resin, non-toxic, odorless, low water absorption, with good overall physical and mechanical properties, such as excellent electrical properties, wear resistance, dimensional stability, chemical resistance and surface gloss, and easy to process molding. The disadvantages are weather resistance, poor heat resistance, and flammability.

Process characteristics of ABS

1,ABS is hygroscopic and moisture-sensitive, so it must be dried and preheated (at least 2 hours at 80~90C) before molding and processing to keep the moisture content below 0.03%.

2,The melt viscosity of ABS resin is less sensitive to temperature (unlike other amorphous resins).The injection temperature of ABS is slightly higher than that of PS, but it cannot be used to increase its viscosity by blindly increasing the temperature. The general processing temperature is 190-235℃.

3,The melt viscosity of ABS is medium, higher than that of PS, HIPS and AS, so a higher injection pressure (500~1000bar) is required.

4,ABS material is better to use medium to high speed injection speed. (Unless the shape of complex, thin-walled parts need to use higher injection speed), the product water mouth position easy to produce air lines.

5,ABS molding temperature is high, the mold temperature is generally adjusted at 25-70 ℃. When producing larger products, the temperature of the fixed mold (front mold) is generally slightly higher than that of the moving mold (back mold) by about 5℃. (The temperature of the mold will affect the finish of the plastic parts, the lower temperature will lead to a lower finish)

6,ABS should not be left in the high temperature barrel for too long (should be less than 30 minutes), otherwise it is easy to decompose and yellow. In addition to ABS resin, there are many plastic products such as: abs profile, PVC profile, PC profile, etc.

Main product

Related Keywords