CNC 5 axis machining

- Payment Type:

- L/C, T/T, D/P

- Incoterm:

- FOB

- Min. Order:

- 100 Piece/Pieces

- Min. Order:

- 100 Piece/Pieces

- Delivery Time:

- 15-45 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen Port

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen Port |

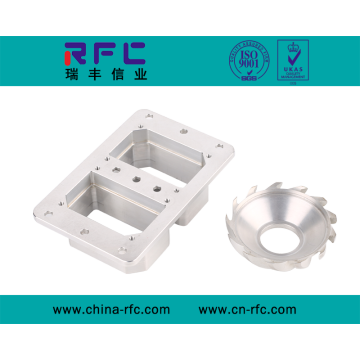

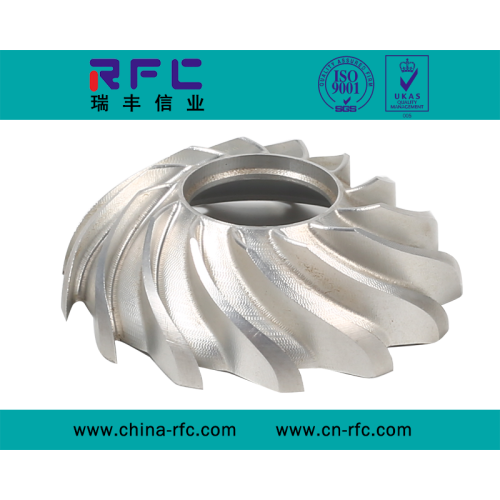

Why choose five-axis CNC machining at RFC PRECISION MACHINE LIMITED:

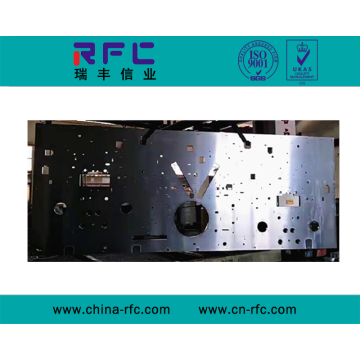

1. Complex Shapes

The major (and most well-known) advantage of five-axis machining is ability to machine complex shapes. The additional movement creates machining angles and arcs that were only previously possible with a multitude of special fixtures or additional setups.

2. Fewer Setups

Five-axis machines can machine nearly every visible surface, excluding the bottom or clamping area. This breadth of ability significantly reduces the need for multiple setups or special fixtures. Of course, another big benefit of fewer (or ideally one) setup is…

3. Relational Accuracy

Imprecision finds a way to seep in with every setup change. Once a part comes out of the machine, precise alignment is lost. By using the same “zero” or “home” location, feature-to-feature accuracy is improved.

4. Better Surface Finish

Using the rotating fourth and fifth axes, the part can be orientated to bring it closer to the cutting tool. If the part can get closer to the cutting tool, then the cutting tool can be shorter. A shorter cutting tool is less susceptible to vibration at higher cutting speeds, which directly impacts surface finish.

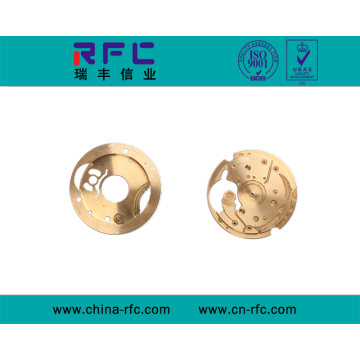

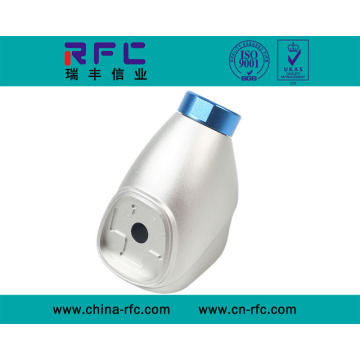

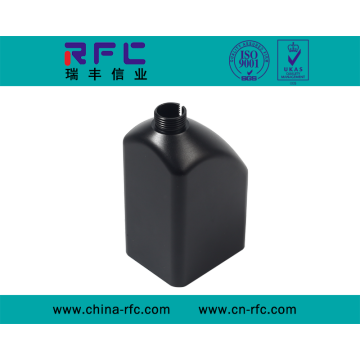

Product name: CNC 5 axis machining

Material: AL7075

Surface treatment: Hard anodizing

Dimensions: diameter 60-30mm

Application: medical equipment