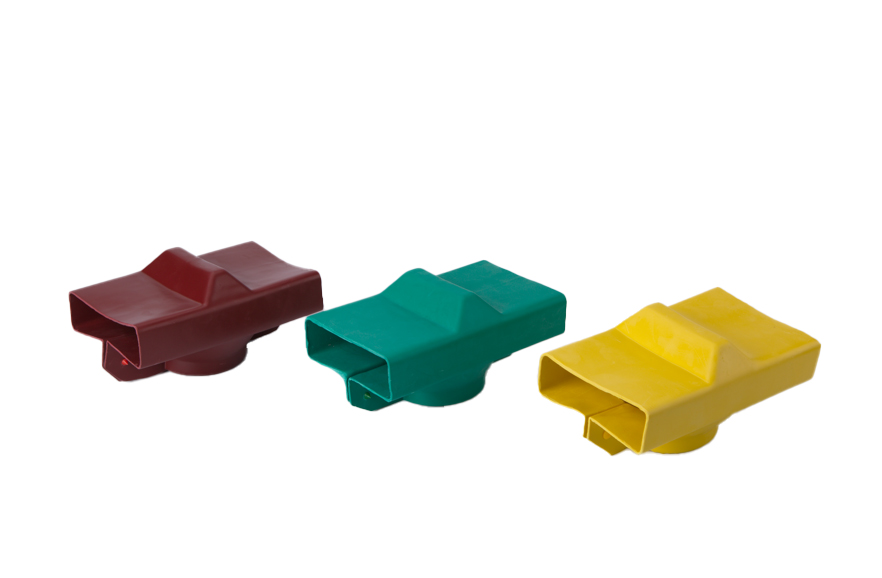

Specially Designed Bushing Cover

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW, FCA, CPT, CIP

- Transportation:

- Ocean, Land, Air

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Transportation: | Ocean,Land,Air |

Product Description

Product Description

SINOFUJI bushing cover is made of radiation cross-linked polyolefin or cross-linked EPDM rubber material.

SINOFUJI adopts new molding process for bushing cover in the purpose of providing the world with first-class products and services.

It is SINOFUJI's concern that the bushing cover made by traditional manufacturing process, had been presented that the appearance is almost irregular, the dimension consistency is poor, and the insulation performance is unsatisfied. While SINOFUJI bushing cover with new molding process presents kinds of advantages:

- Superior performance of aging and electrical insulation.

- regular appearance and accurate consistency in dimensions.

- Could be easily met with personalized design with high production efficiency.

- High material utilization thus total cost is lower than that of traditional process.

- In the cater for requirements of all kinds of special and complex shape thus to expand application scope of this products.

- It is environment friendly cause the cutted raw materials in the manufacturing process can be recycled for production use.

Features:

- Color: Red Yellow Green Black

- Working Temperature: -40℃ upto 105℃

- Suitable for 1KV upto 35KV connection

- Radiation Cross linking Material (Polyolefin or EPDM Rubber)

- Quick and Easy Installation

- Short Circuit and Leakage are Prevented

- Facilitate Routine Inspection and Maintenance

- Resistant to Moisture and Dust

- In comply with RoHS Standard

- Customized

- Provide Insulation and Enhancement for Busbar

- Supply Protection and Insulation for Switchboard and Substation

Technical Data:

| Testing Items | Guaranteed Date Under Each Material | Testing Method | |

| Polyolefin | EPDM | ||

| Tensile Strength | ≧10Mpa | ≧10Mpa | ASTM D 2671 |

| Elongation At Break | ≧300% | ≧1000% | ASTM D 2671 |

| Thermo Aging Tensile Strength | ≧6.9Mpa | ≧9Mpa | 90℃/70hrs |

| Thermo Aging Elongation At Break | ≧150% | ≧500% | 90℃/70hrs |

| Heat Shock | No Cracking | No Cracking | JB7829 |

| Oxygen Index | ≧28 | — | GB/T2406 |

| Dielectric Strength | ≧20KV/mm | ≧30KV/mm | IEC243 |

| Dielectric Constant | 2~3 | 2~3 | IEC250 |

| Volume Resistence | ≧1×1014Ω·cm | ≧4.5×1014Ω·cm | IEC93 |

Related Keywords

Related Keywords