EPDM Cold Shrink Tube for Connector Sealing

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|

EPDM Cold Shrink Tube for Connector Sealing

Description

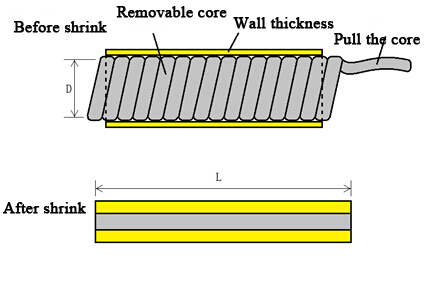

RUBLS-EPDM, 1/2" Feeder Cable Protection EPDM Insulation Cold Shrink Sleeve Shrinkable Tube is a series of open-ended, tubular rubber sleeves, which are factory expanded and assembled onto a removable core. EPDM Insulation Cold Shrink Sleeve Shrinkable Tube is supplied for field installation in this pre-stretched condition. The core is removed after the tube has been positioned for installation over an in line connection, terminal lug, etc., allowing the tube to shrink and form a waterproof seal. Insulation Cold Shrink Sleeve Shrinkable Tube is made of EPDM rubber, which contains no chlorides or sulphurs. Various diameter sizes will cover a range of 1000 volt cables, copper and aluminum conductors.

Features

² Excellent weather resistance, ultraviolet aging resistance and higher embrittlement resistance than heat shrink tubing

² More resistant to slab and prick, abrasion, acid and alkali than silicone cold shrink tubing

² Simultaneously expands and shrinks with workpieces without clearances, seals tight in harsh environment

² Stably sealing the workpieces in windy environment

² Well suited for cable less than 1KV

² Seals tight, retains its resiliency and pressure even after prolonged years of ageing and exposure.

² Simple , safe installation, requires no tools or special training. No torches or heat work required.

² Diameter shrinkage:≥50%

² Sealing class IP68

Application

Primary electrical insulation for all solid dielectric (rubber and plastic) insulated wire and cable splices rated to 1000volts

² Meets ANSI C119.1, directly buriable or submersible

² For indoor, outdoor, or overhead use

² Physical protection and moisture sealing for high-voltage, air-insulated connectors and lugs such as spacer cable andlug connections to bus bar

² Insulation of secondary splices copper or aluminum conductors

² Relocation of service

² Dig-in repairs, sheath repairs

² Insulation of inline conductor transition connectors

² Sealing of coax cables with Type N or 7/16 DIN connectors on wireless communication towers

Technical Performance

|

Properties |

Typical Data |

Test method |

|

HS |

49 A |

ASTM D 2240-75 |

|

Tensile Strength |

9.8 MPa |

ASTM D412-75 |

|

Elongation at break |

720% |

ASTM D412-75 |

|

Tear Strength |

27 N/ mm |

ASTM D624C-73 |

|

Dielectric Strength |

14.3kV/mm |

ASTM 149-75 |

|

Dielectric Constants |

5.0(Initial data)/5.6(90degree in the water for 7 days)) |

/ |

|

Anti-enzyme (bacteria) |

The 28 day exposure without growth |

ASTM G-21 |

|

UV Resistant |

UV irradiation for 2000 hours without aging |

ASTM G-53 |

Structure

Related Keywords