Mold Trial 20 20

-

USD10000≥1 Others

- Payment Type:

- T/T

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Delivery Time:

- 30 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | T/T |

|---|

Product Description

Product Description

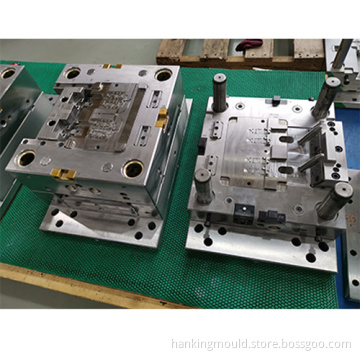

Plastic Mould Trial

In our trial shop, we have 7 injection molding machines with a clamping force ranging from 25 T–250 T including one new vertical machine(120T), we can provide professional mold trial and injection molding service, the machines are focused on mold trials and small batch production.

Our workshop is equipped with material dehumidifying dryers, cooling controllers and hot runner controllers.

Plastic Resin

We can process a variety of plastic materials, including advanced engineering materials with glass fibers (15-50%) like PPA, PPS, PSU, PA6, PA66, PBT, PEEK, LCP, GRIVORY, PET etc..

We are also familiar with PC, ABS, PC/ABS, ASA, PMMA, POM, PP etc..

Mold tests simulating production conditions are performed on every mold

Using the latest scientific molding process and equipment, Hanking is capable to analyze every step of the injection molding process to assist in debugging and qualifying the moulds.

Related News

Development Trend of Mould Industry in China

Four Specific Action Areas for China's Injection Molding Industry

Injection Mold Building Process

Shape-Following Cooling Can Greatly Improve The Production Efficiency Of Injection Molds

How to Make Good Plastic Part?

Global Precision Mould Material Conference

HanKing Mould Enginering Ltd. started the business in the year of 1996 as a injection mold maker company in the line of mold making and injection molding in Longgang, Shenzhen, China.

In our trial shop, we have 7 injection molding machines with a clamping force ranging from 25 T–250 T including one new vertical machine(120T), we can provide professional mold trial and injection molding service, the machines are focused on mold trials and small batch production.

Our workshop is equipped with material dehumidifying dryers, cooling controllers and hot runner controllers.

Plastic Resin

We can process a variety of plastic materials, including advanced engineering materials with glass fibers (15-50%) like PPA, PPS, PSU, PA6, PA66, PBT, PEEK, LCP, GRIVORY, PET etc..

We are also familiar with PC, ABS, PC/ABS, ASA, PMMA, POM, PP etc..

Mold tests simulating production conditions are performed on every mold

Using the latest scientific molding process and equipment, Hanking is capable to analyze every step of the injection molding process to assist in debugging and qualifying the moulds.

Related News

Development Trend of Mould Industry in China

Four Specific Action Areas for China's Injection Molding Industry

Injection Mold Building Process

Shape-Following Cooling Can Greatly Improve The Production Efficiency Of Injection Molds

How to Make Good Plastic Part?

Global Precision Mould Material Conference

HanKing Mould Enginering Ltd. started the business in the year of 1996 as a injection mold maker company in the line of mold making and injection molding in Longgang, Shenzhen, China.