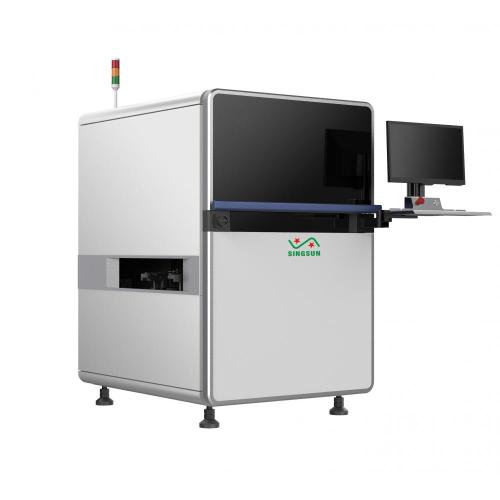

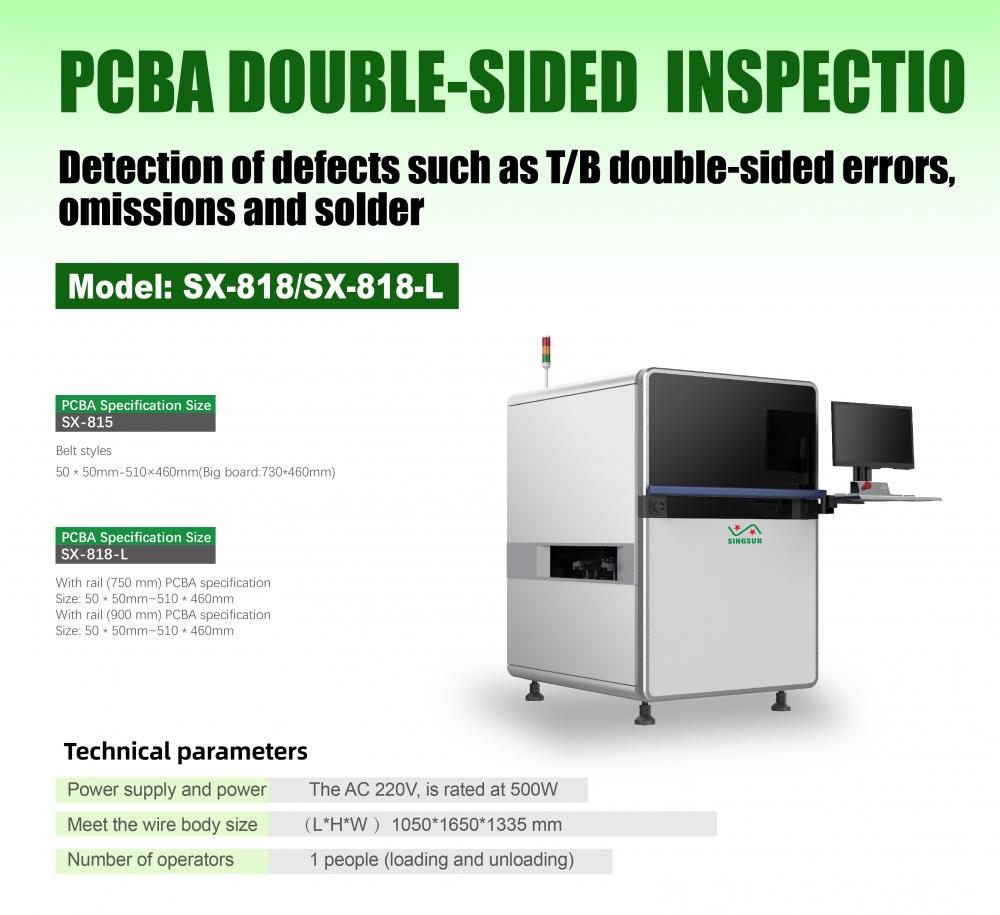

SMT offline and online Automatic optical inspection Machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen, China |

|---|---|

| Supply Ability: | 200 sets/month |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB,EXW |

| Port: | Shenzhen |

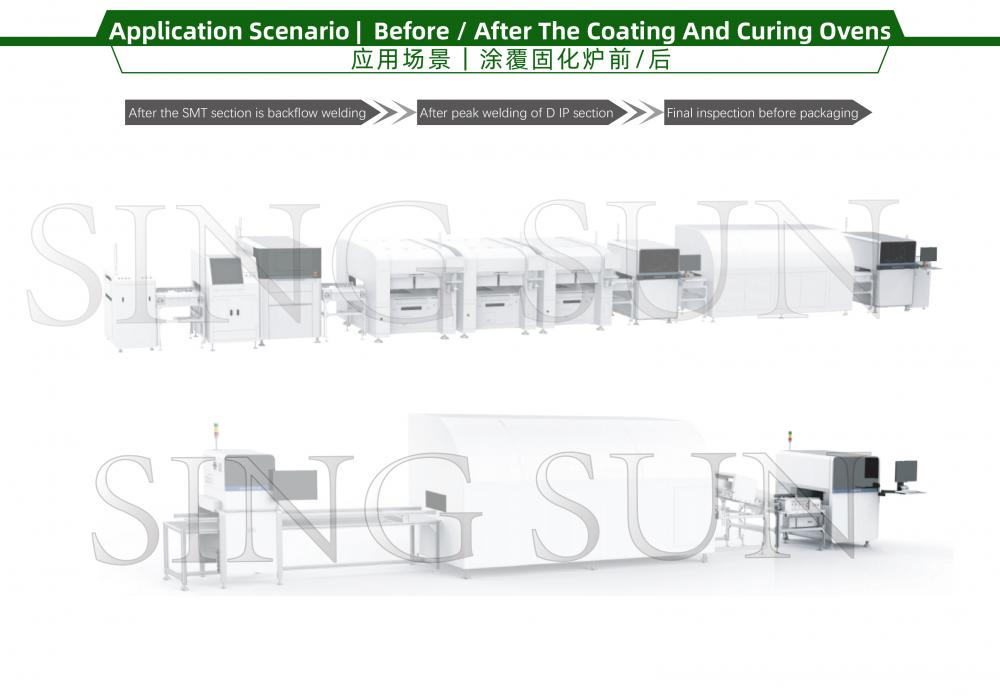

Application behind Wave Soldering/behind reflow/before packing

Product Feature:

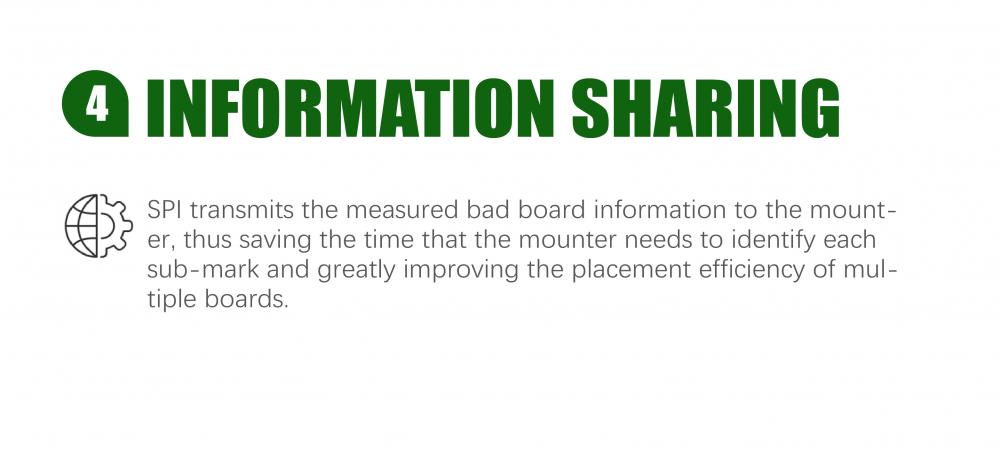

√More accurate inspection by AI intelligent algorithm

√Faster inspection with Dual Side

√Simple operation by smart minimalist programming

√Multi-apply to benefit different assessment

Product Core Function:

√Support Mixed model and panel inspection

Auto recognize nixed model and panel inspection by AI positioning algorithm

√Online/offline programming

Online programming to save line down time

√Fuzzy feature inspection

Intelligently inspect fuzzy feature such as color ring resistor, same-color feature materials, silk screen interference on surface

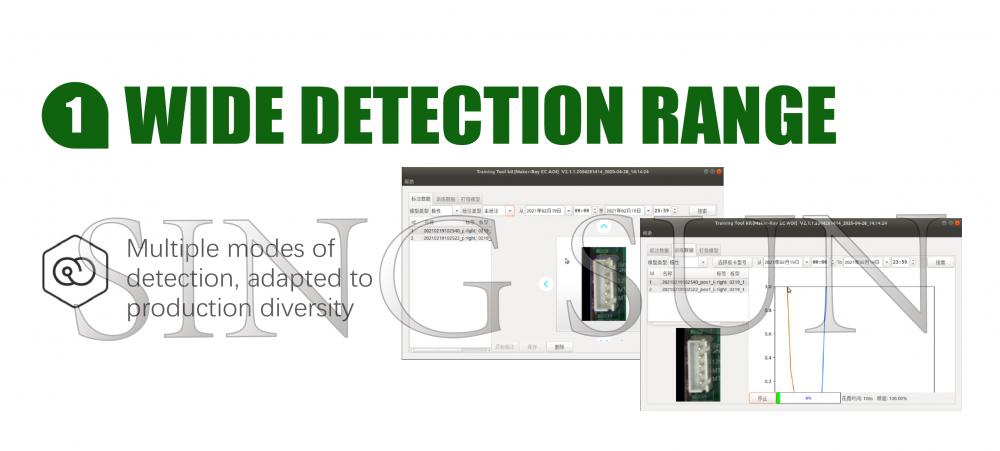

√AI training tool

Model self-training for special components, reduce false positive rate by continuous learning to improve inspection accuracy

√Multi-function

Multi-purpose, inspect component defects of SMD, THT, solder joint

√SPC data analysis

Real-time data recording and analysis, providing evidence for process improvement, and real-time trace data

Product Software:

² Operating system: Ubuntu 18.04 LTS 64bit

² Function: Remote control, Remote assistance, CAD and Gerber file import and user-defined model training

² Communication method: Standard SMEMA

² Data output: Auto generated statistic analysis SPC

² Special function: Automatic search of elements and quick programming

Product Hardware:

² CPU:intel i7

² Display card:Nvidia GTX1050Ti

² Memory:64G DDR4 ,240G SSD+2T Mechanical Hard Disk

² Network:1000M Wired Network Card

² Display: 23.8 inch FHD display

² Movement mechanism: High precision lead screw + servo motor

² Rail width control: Manual/Auto

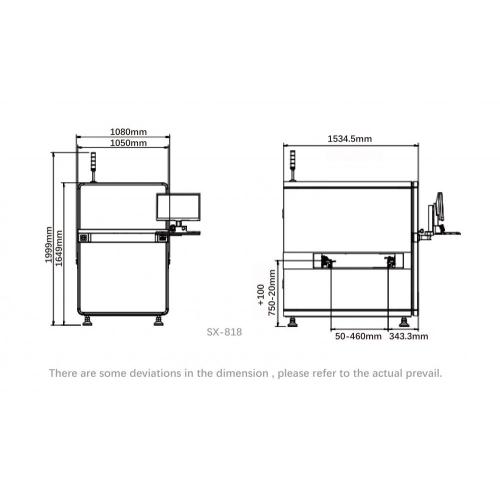

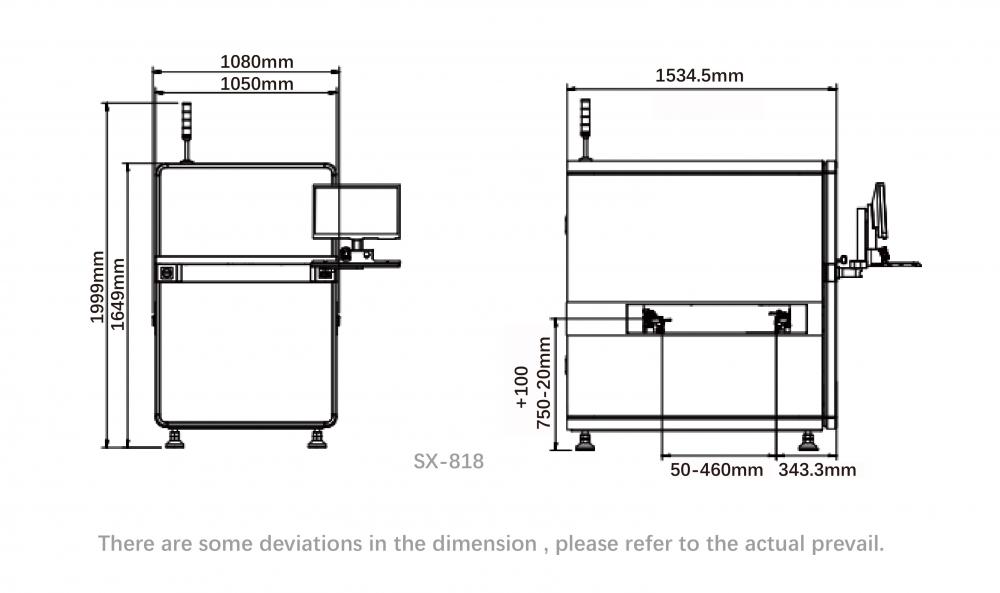

Product Structure Diagram:

Product Advantage:

² Inspection-related

Components: Absent, Reversed, Misalignment, Broken, Extra, Foreign material, Stained

Other function: Bar code Recognition/QR code Recognition/OCR

Solder: insufficient, Excessive, Bridge, No foot, Solder void, etc

Mixing boards inspection: Support mixed board production and calling program automatically

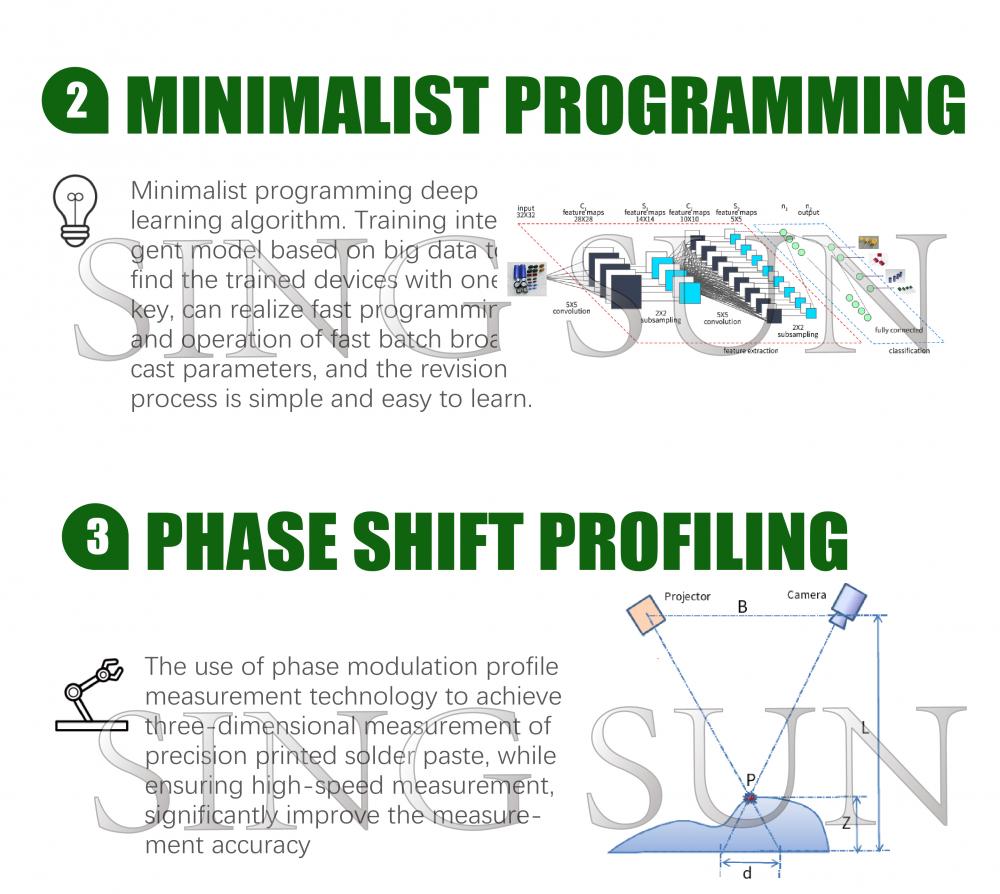

Algorithm: CNN, Color contrast, Outline recognition, Off set inspection, Template matching, Character comparison, OCR, etc.

Speed: 0.23sec/FOV

Our company

Related Keywords