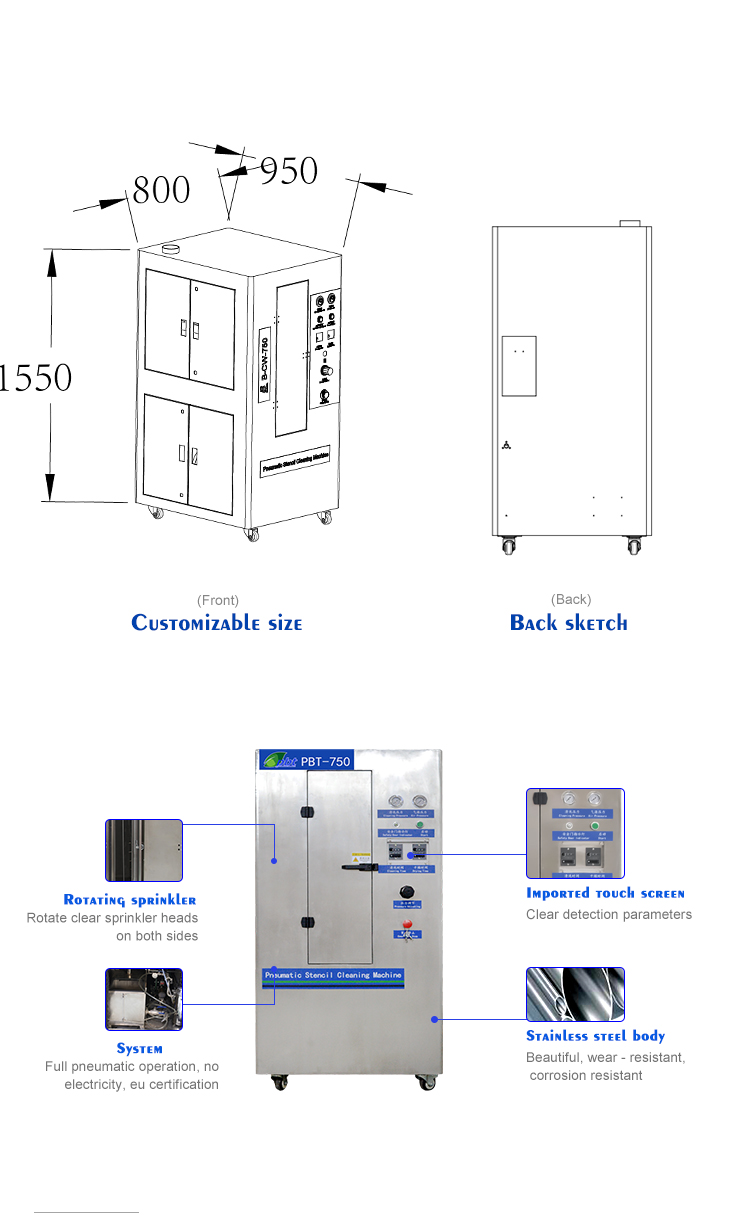

Full Pneumatic Cleaning Machine for SMT Stencil Cleaner

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB

- Delivery Time:

- 20 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | Strong |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

SMT stencil cleaner

Product Description

SMT Stencil cleaner

Stencil Clean Solution

Stencil Cleaner System

Feature:

1.Apply to water-based cleaning solution to clean solder paste stencil and red glue stencil

2.Double spray system (eight spray bar cleaning), double spray system (four air knife air cutting), faster cleaning efficiency, 1pcs/eath time

3.Process flow: cleaning(2-3min) - chemical isolation - rinsing (open-loop/closed-loop)(0.5-1min) - air cutting1(1-2min) - drying;

4.Simple operation, adjustable parameters,Filtration accuracy 0.22um

5.The whole stainless steel body is durable, acid and alkaline resistant cleaning fluid.

The main products of ROC: SMT cleaning machine, PSA oxygen / nitrogen generator, wafer cleaning equipment, PCBA cleaning machine, PCB separator, SMT spare parts, reflow / wave soldering machine, SMT nozzle, SMT feeder etc. If there is any need, please contact us.

Technical parameters:

1. Cleaning max size:750mm(L) ×750mm(W) × 40mm(H)

2.Cleaning fluid Capacity:60L(max)×2PCS

3.Cleaning Process flow:The stencil moves up and down, and eight spray rods spray high-pressure liquid (cleaning → wind cutting → rinse → wind cutting → dry).

4.Rinse method: spray, open or closed loop

5.Drying method: four air knife air cutting drying

6.Clean liquid for recycling and filtration,recycled filter 0.45um

7.Air supply:0.45Mpa~ 0.7Mpa

8.Air consumption:200-400L/Min

9. power supply :AC380V 50HZ 60A

10. net weight:≈450Kg

11.Vent size:Φ120mm(W)

13. The machine size:1000mm(L) ×1520mm(W) × 1950mm(H)

| Size of cleaning basket | disc diameter 1000mm x 520mm (H) |

| Diluent tank capacity | 65L (MAX) |

| Rinse tank capacity | 65L (MAX) |

| Setting drying time | 5 minutes |

| Cleaning mode | 360 degree rotating disc; 720 degree high pressure cleaning liquid injection of spray rod |

| Equipment gas supply | 0.45Mpa~ 0.7Mpa |

| Outlet size | Φ120(W)×30mm(H) |

| Rinsing drainage flow | 40 L/Min |

| Chemical fluid filter | 10μm |

| DI rinse filter | 0.45μm |

Related Keywords