Oxygen Generator for Petrochemical Industry

-

$10000.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB,EXW,CIF |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Oxygen Generator for Petrochemical Industry

Industrial Oxygen Plant Oxygen reactions in petroleum and chemical processes use rich oxygen instead of air to carry out oxidation reactions, which can increase the reaction speed and the output of chemical products.

Product features:

● Fast starting speed, in a short time can provide qualified oxygen;

● Automatic operation of the equipment, the whole process can achieve unattended;

● High efficiency molecular sieve filling, tighter, more solid, longer service life;

● Pressure, purity, flow stability adjustable, to meet the different needs of customers;

● Reasonable structure, safe and stable, low energy consumption;

Product Principle:

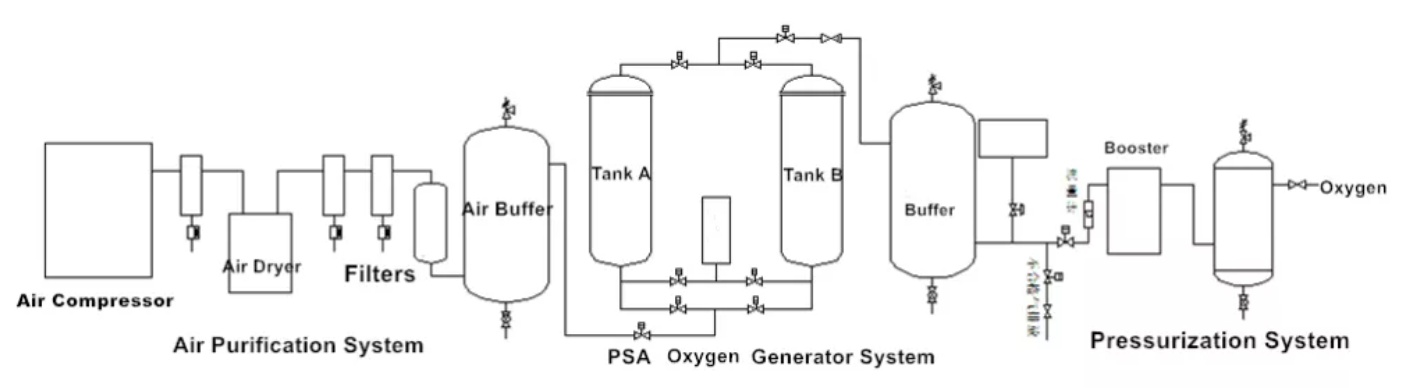

The pressure swing adsorption PSA Oxygen Generation Plant uses clean compressed air as the raw material and high-quality zeolite molecular sieve as the adsorbent to produce oxygen from the air under a certain pressure. The purified and dried compressed air is subjected to pressure adsorption and decompression desorption in the adsorber. Due to the aerodynamic effect, the diffusion rate of nitrogen in the micropores of zeolite molecular sieve is much faster than that of oxygen, nitrogen is preferentially adsorbed by zeolite molecular sieve, and oxygen is enriched in the gas phase to form finished oxygen. After decompression to normal pressure, the adsorbent desorbs the adsorbed nitrogen and other impurities to realize regeneration. Generally, two adsorption towers are set up in the system, one tower absorbs oxygen and the other tower desorbs and regenerates. The PLC program controller controls the opening and closing of the pneumatic valve to make the two towers circulate alternately, thereby obtaining oxygen with high purity (93 %±3%).

In response to the different requirements of different users in different industries for the use of oxygen, our Kunpeng team provides personalized and professional Gas Production Equipment to fully meet the gas consumption requirements of different users.

Related Keywords