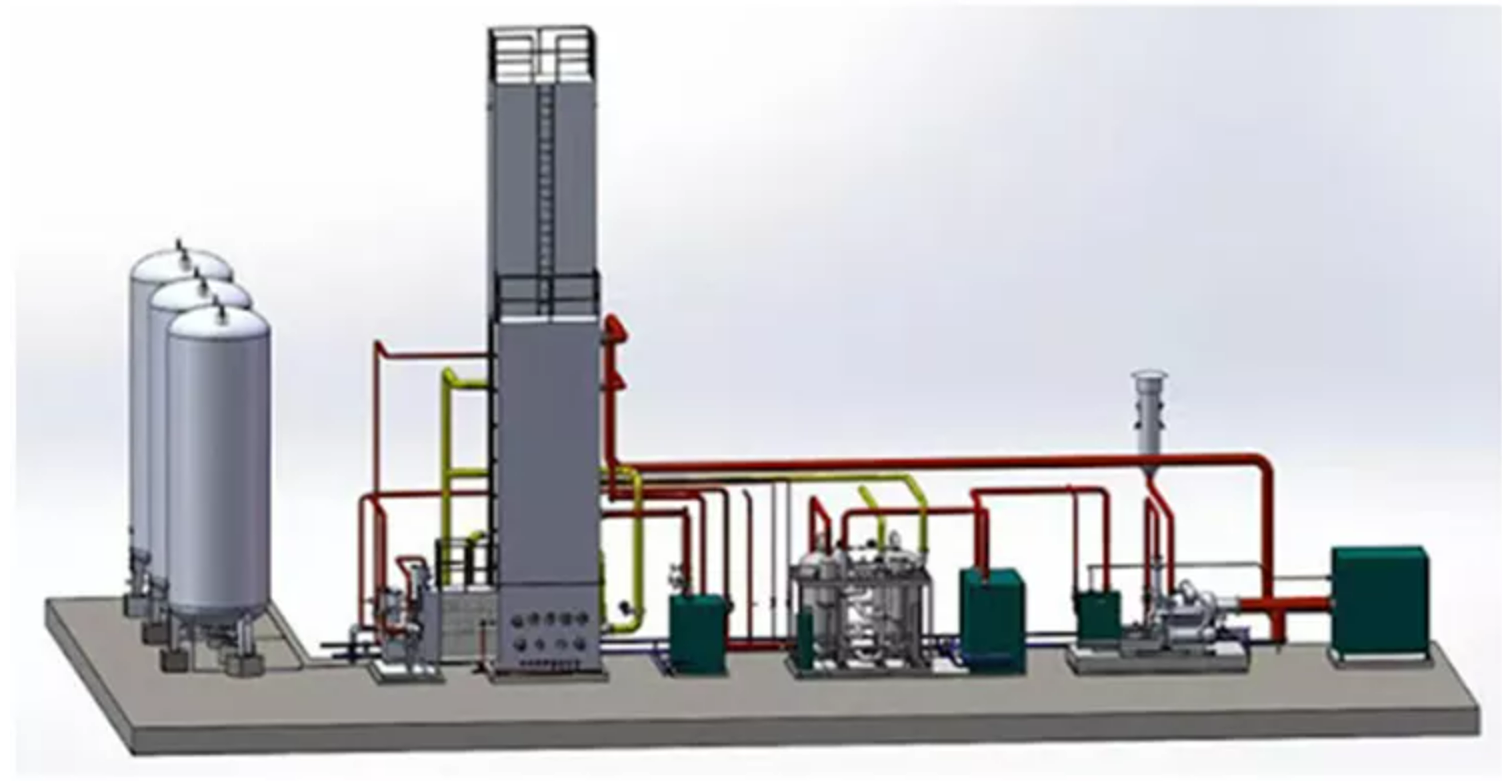

Industrial O2 Oxygen Generator Air Separation Plant

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | strong |

| Payment Type: | T/T |

| Incoterm: | FOB,EXW,CIF |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Cryogenic Air Separation Information

The cryogenic method is to compress and cool the air first, and liquefy the air, and use the difference in the boiling points of the oxygen and nitrogen components to contact the gas and liquid on the rectification tray for mass and heat exchange. The components are continuously condensed from the vapor into liquid, and the nitrogen components with low boiling points are continuously transferred into the vapor, so that the nitrogen content in the ascending vapor is continuously increased, and the oxygen content in the downstream liquid is getting higher and higher, so that oxygen, Nitrogen is separated, which is air distillation.

Oxygen Plant Modern Air Separation Process Characteristics

1. Using normal temperature molecular sieve purification, it is more effective to remove harmful substances in the air, the switching loss is small, and the continuous operation period of the device is designed to be longer than two years;

2. Use structured packing upper tower to replace the sieve plate tower, so that the resistance of the upper tower is greatly reduced (only 1/4 of the resistance of the sieve plate), the exhaust pressure of the air compressor is reduced, and the energy consumption of the device is reduced by 5% to 7%;

3. The oxygen extraction rate of air separation equipment is improved, and the oxygen device purity is above 99.6%;

4. The rectification adopts full rectification hydrogen-free argon production technology, and the argon tower adopts a structured packing tower, which omits hydrogen production equipment, simplifies the process, and saves investment and operating costs;

5. The molecular sieve purification system adopts a double-layer bed structure, which greatly prolongs the service life of the molecular sieve and reduces the bed resistance, making the operation of the air separation unit safer and more reliable;

6. Adopt high-efficiency supercharged turbo expander technology, which can recover part of the energy very well, and the cooling efficiency of the expander is above 85%;

7. DCS control technology is adopted to realize the integrated control of central control, machine room and local control, which can effectively monitor the production process of the whole set of Cryogenic Oxygen Air Separation Unit.