High Purity Oxygen Generator Cylinder Filling Plant

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | strong |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

High Purity PSA Oxygen Generator System

Features:

● Fast start-up, qualified oxygen can be provided within 15-30 minutes;

● The equipment is fully automatic, and the whole process can be unattended;

● Efficient molecular sieve packing, tighter, more solid, and longer service life;

● The pressure, purity, and flow are stable and adjustable to meet the different needs of customers;

● Reasonable structure, safety and stability, low energy consumption;

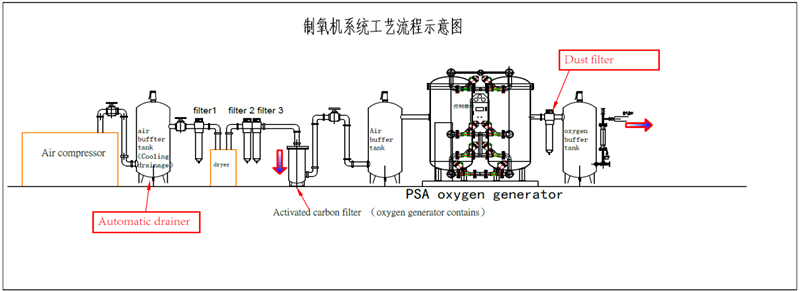

Principle:PSA Oxygen Generation Plant

This process uses molecular sieves with capillary pores as adsorbents, and utilizes the difference in diffusion rate of oxygen molecule O2 and nitrogen molecule N2 in molecular sieve. Nitrogen and CO2 molecules in the air are absorbed into the pores, while most of the oxygen molecules O2 flow through the capillary pores into the oxygen collecting and storing tank in the later stage to be enriched. Molecular sieve has the characteristics of adding air pressure adsorption capacity increasing, and reducing air pressure adsorption capacity reducing, using this characteristic, the pressure swing adsorption method can be used to carry out continuous and uninterrupted oxygen and nitrogen separation. So as to achieve the preparation of 35%-95% purity room temperature oxygen. The PSA oxygen generator adopts a dual-tower parallel design. When tower A reaches saturation, it will switch to tower B for oxygen production through pressure equalization and other processes. At this time, tower A is vented and purged and regenerated, waiting for the next cycle of the oxygen generator; thus, double-tower alternate oxygen production is realized. In the latter stage of the oxygen collection process tank, high-purity continuous supply of oxygen is obtained, and finally the pressure is stabilized by adjusting the pressure and then transported to the gas point through the pipeline.

Oxygen production: 5 ~ 1000Nm3/h

Purity of oxygen: 93%±2%

Oxygen pressure: ≤3 bar(Adjustable)

Dew point: ≤-40ºC(Adjustable)

| Model | O2 Cpacity(Nm3/h) | Purity |

| HO2005 | 5 | 93%±2% |

| HO2010 | 10 | 93%±2% |

| HO2020 | 20 | 93%±2% |

| HO2040 | 40 | 93%±2% |

| HO2050 | 50 | 93%±2% |

| HO2080 | 80 | 93%±2% |

| HO2100 | 100 | 93%±2% |

| HO2150 | 150 | 93%±2% |

| HO2200 | 200 | 93%±2% |

⊙ The equipment has the advantages of low energy consumption, low cost, strong adaptability, fast gas production and easy adjustment of purity.

⊙ Perfect process design and best use effect;

⊙ Modular design is designed to save land area.

⊙ The operation is simple, the performance is stable, the automation level is high, and it can be realized without operation.

⊙ Reasonable internal components, uniform air distribution, and reduce the high speed impact of airflow;

⊙ Special carbon molecular sieve protection measures to extend the life of carbon molecular sieve.

⊙ The key components of famous brands are the effective guarantee of equipment quality.

⊙ The automatic emptying device of national patent technology guarantees the nitrogen quality of finished products.

⊙ It has many functions of fault diagnosis, alarm and automatic processing.

⊙ Optional touch screen display, dew point detection, energy saving control, DCS communication and so on.

Send Inquiry(Oxygen Separation Plant) Please bring the following description, we have more models to recommend to you !

| Technical Information | Your Kind Requirement |

| Capacity |

_________Nm³/h |

| Purity | _________% |

| Outlet Pressure | _________Mpa or Bar |

| Power | ________V/HZ |

Related Keywords