PSA Nitrogen Generator Food Preservation Nitrogen Machine

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB,CIF,EXW |

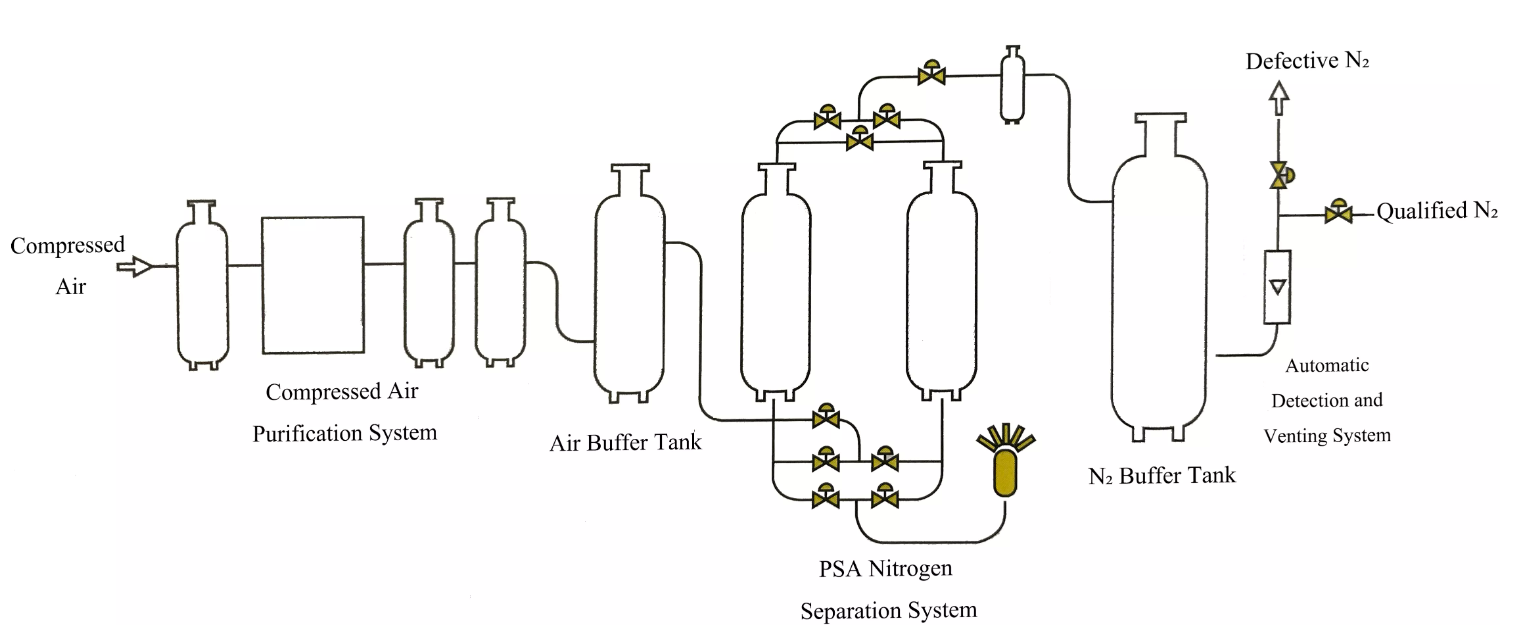

Gas Production Equipment constructed according to the principle of operation P.S.A. (Pressure Swing Adsorption) and

are composed by a minimum of two absorbers filled up with molecular sieve.The absorbers are crossed alternatively by the

compressed air (previously purified in order to eliminate oil, humidity and powders) and produce nitrogen or oxygen. While a

container, crossed by the compressed air, produces gas, the other regenerates itself losing to pressure atmosphere the gases

previously adsorbed. The process comes repeated in cyclical way. The generators are managed by a PLC.

Process Flow Brief Description

Air compressor:

The Air compressor's function is to supply the compressed air which is the source of material and power of the Nitrogen Systems, Normally the air compressor has micro oil content and oil Free type because the pressure is stable, and the air quality is high. Of course, the air compressor is the main power consumption.

Air tank:

Stabilize the air fluctuation, keep the air going through the purification parts, and remove more oil and water impurities, meanwhile, it can support the air capacity to PSA nitrogen generator for a short time, guarantee the pressure rise of adsorption vessels and keep the whole system running smoothly.

Refrigerated Air Dryer:

According to the freezing and drying principle of air. it takes the frozen machine to cool down the compressed air till the relative dew point and the water in the air will be drained out by the drainer valve, and then the compressed air has been dried to the desired dew point.

Filter (Super Line Filter):

Further, filter the impurities of compressed air, it can be used for dust, particle, liquid water and oil, and the substance above

Air buffer tank:

Using for nitrogen generator with a big capacity, can buffer and stabilize the pressure.

Filter (Super Activated carbon filter):

Be used for the smog oil and hydrocarbon steam, it can remove the particle which is at 0. 01 u m(0.003ppm w/w Maxoil content).

All systems are designed for un-attended operation and automatic nitrogen demand adjustment.

2). Lower Space Requirement

The design and Instrument makes the plant size very compact,assembly on skids,prefabricated from factory.

3). Fast Start-up

Start-up time is only 5 minutes to get desired Nitrogen purity.So these units can be switched ON&OFF as per Nitrogen demand changes.

4). High Reliabiity

Very reliable for continuous and steady operation with constant nitrogen purity, plant availability time is better than 99% always.

5). Molecular Sieves life

Expected Molecular sieves life is around 15-years i.e. whole life time of nitrogen plant, so no replacement costs.

6). Adjustable

By altering flow,you can deliver nitrogen with precisely the right purity.

Kunpeng supply all kinds of small and medium sized air separation plants, nitrogen production equipment, oxygen production equipment and psa nitrogen & liquid nitrogen plant, etc. We will continue to develop and promote industrial applications and related products to help you improve production efficiency. In addition, we will also provide a range of industrial services, for your business to provide full support.

Related Keywords