Nitrogen Generators for Edible Oil Filling System

-

$10000.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | strong |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Nitrogen Generator for Vegetable Oil (Edible Oil) Industry

For most capacities, 99.999% purity Psa Nitrogen Generator, one-time production, no need for secondary purification

Nitrogen Generator for Vegetable Oil (Edible Oil) Industry

The edible oil Nitrogen Preserves Freshness technology uses pressure adsorption and addition to absorb the additives of edible oil and air additives, which is a healthy and effective technology in the field of edible oil preservation, and is also a widely used method of food oil preservation.

After using nitrogen filling to keep fresh, the nutrient content in the package is also low, avoiding the rancidity of the food. At the same time, positioning the food and squeezing the aromatic hydrocarbons in the food does not affect the sexual changes of the food, and does not affect the food to maintain the original ecological fresh taste. It can ensure no contact during the whole process, and can also reduce the corresponding loss rate. The fresh-keeping ability during transportation is greatly improved. Another thing worth mentioning is that the fresh-keeping ability of repackaged products is not small, which is for those who need to stock up. For friends, it is also a highlight.

Pharmaceutical production has high requirements for nitrogen:

1. The purity of nitrogen is required to be high, generally 99%-99.99%;

2. Nitrogen is required to be free of dust and heat, and can be used for potting of injections;

3. Nitrogen is required to maintain a constant pressure supply during the production process to ensure the normal operation of production.

Service:

1.reasonable activated carbon modular design, convenient and quicker to replace dispense with professional

personnel.

2.Can provide purties99.999%Nitrogen gas at a time , purity stability, pressure stability

3.Using Siemens HMI,display the parameters , such as the nitrogen purity and real-time nitrogen flow, more humane.

4.A key boot,automatic oxygen supply after the N2 purity qualified

5.Adopt imported BURKERT valve, long service life, stable property

6.Adopt imported SMC meter, measuring gas flow accurately, stable performance

Related Products: SMT Cleaning Machine, PSA oxygen / nitrogen generator, SMT Spare Parts etc. If any need, please contact us.、

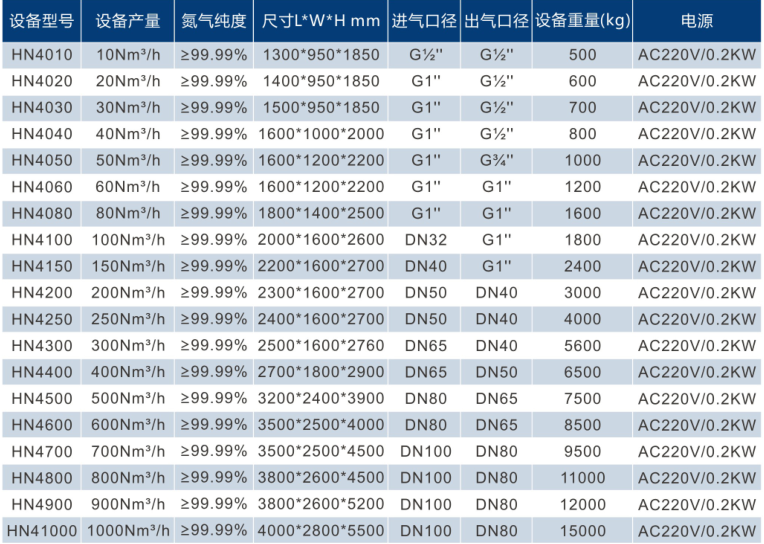

Nitrogen capacity: 1- 2000Nm3/h

Nitrogen purity: 95%-99.999%

Nitrogen pressure: 0.5-0.8Mpa( boost for high pressure

Nitrogen dew point: s-40.C(Atmosphere pressure)

Customized pressure, purity and capacity ranges.

Technical characteristics

1.The material source is from the nature, the system only needs compressed air and power, so the cost of power and operation is less

2. Nitrogen purity is easy to adjust, it is only affected by the capacity, purity of normal nitrogen is at the range of 95%-99.99%(can be adjusted), purity of high nitrogen is at the range of 99%-99.999%(can be adjusted)

3. The system is automatic, quick starting and no need to monitor. One button for start and stop, run 10-15 minutes to generate the N2 air

4. The working progress is easy, the configuration is compact, the landing space is less and the environment is well-adapted

5. Snow storm filling can avoid the damage of CMs

6. Digital flow meter has pressure compensation, it is highly precise meter which can monitor the progress, it can test quick flow and accumulate the total capacity

Send Inquiry Please bring the following description, we have more models to recommend to you ~! Thank you~!

| Technical Information | Your Kind Requirement |

| Capacity |

_________Nm³/h |

| Purity | _________% |

| Outlet Pressure | _________Mpa or Bar |

| Power |

________V/HZ |

Related Keywords