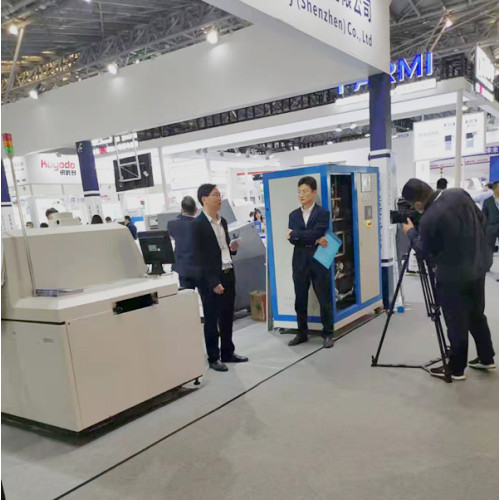

Nitrogen Generator Used in the SMT Lead-Free Soldering

-

$10000.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB,CIF,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Advantages of SMT Industrial Nitrogen Plant

With the improvement of assembly density and the emergence of fine pitch (Fine pitch) assembly technology, nitrogen-filled reflow soldering process and equipment have been produced, which has improved the quality and yield of reflow soldering, and has become the development direction of reflow soldering. Nitrogen reflow soldering has the following advantages:

1. Faster wetting of terminals and pads;

2. Little change in solderability;

3. Improved the appearance of flux residue and solder joint surface;

4. Rapid cooling without copper oxidation.

Nitrogen is used as a shielding gas, and its main function in welding is to exclude oxygen during welding, increase weldability, and prevent re-oxidation. Soldering is reliable. In addition to selecting the appropriate solder, flux is generally required. The flux is mainly to remove the oxide on the soldering part of the SMA component before soldering and prevent re-oxidation of the soldering part, and form excellent wetting conditions for the solder to improve solderability.

Nitrogen Generator Used in the SMT Lead-free Soldering

Why use PSA Nitrogen Generator for lead-free process?

Lead-free has put forward many new requirements for reflow soldering and other equipment, mainly including: higher heating capacity, thermal stability under no-load and load conditions, materials suitable for high-temperature work, good thermal insulation, and excellent temperature uniformity Performance, nitrogen leak-proof ability, flexibility of temperature curve, stronger cooling capacity, etc. In the process, the use of nitrogen atmosphere can well meet these requirements, avoiding and reducing the defects produced in the welding process of the product.

SMT PSA Nitrogen Generator System refers to the application of nitrogen generator in the SMT industry. SMT surface mount technology (Surface Mount Technology) (abbreviation for Surface Mounted Technology) is the most popular technology and process in the electronics assembly industry. The reason why nitrogen is selected as a protective gas in many industries is mainly because of the high cohesive energy of nitrogen. The use of nitrogen reflow soldering is mainly to enhance the welding quality, so that welding occurs in an environment with very little oxygen content (100PPM), which can avoid Oxidation of components.

We have been engaged in the gas industry for more than ten years, have a professional team, and provide customized one-stop services. Welcome to contact us for more information about Gas Production Equipment.

Related Keywords