Nitrogen Generation Systems for Food Processing Plant

-

$10000.00≥1 Others

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Air, Land, Others

- Port:

- FOB 上海

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Transportation: | Ocean,Air,Land,Others |

| Port: | FOB 上海 |

Nitrogen Systems for Food Processing Plant

The nitrogen generator is a nitrogen production equipment designed and manufactured according to pressure swing adsorption technology. The nitrogen generator uses high-quality imported carbon molecular sieve (CMS) as the adsorbent, and uses pressure swing adsorption (PSA) at room temperature to separate air to produce high-purity nitrogen. Usually two adsorption towers are used in parallel, and the imported PLC controls the imported pneumatic valve to automatically operate, alternately perform pressurized adsorption and decompression regeneration, complete the nitrogen and oxygen separation, and obtain the required high-purity nitrogen. Nitrogen under the same pressure.

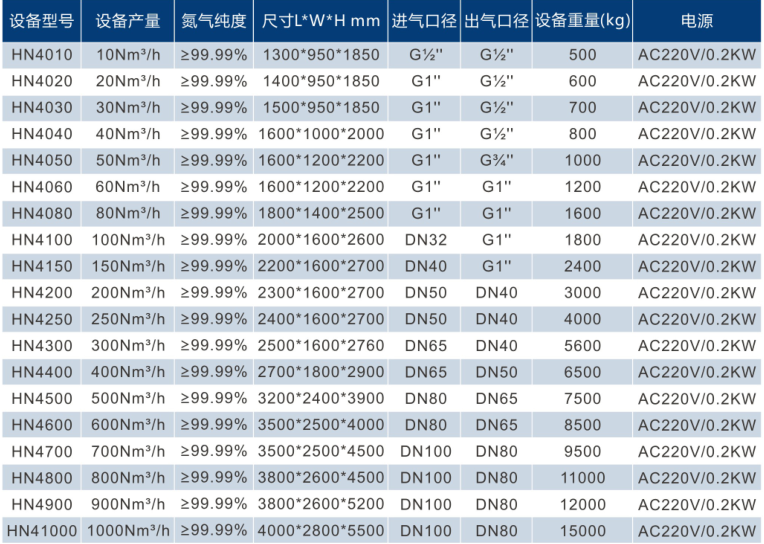

Gas Production Equipment Details

Advantages of PSA nitrogen generator

1. The cost of the nitrogen generator is low. For the same thing, if we use manual injection of nitrogen, it will take time and effort and lead to poor control of the injected amount. The nitrogen generator can inject the same amount of nitrogen into the product packaging at one time according to our needs. nitrogen.

2. The durability rate of the nitrogen generator is very high. On the production line, the working efficiency of the nitrogen generator is comparable to the workload of many employees, while its failure rate is very low.

3. The maintenance of the nitrogen generator is very simple. In the daily use process, as long as it is operated correctly, it is enough to do some maintenance on the parts.

PSA Nitrogen Generator System is used worldwide.Food packing, Food storing, Electric & Electronic industry, Petro-gas & Oil field, Chemicals & Petro-chemicals, Coal-mine, Metallurgy, Pharmacy, SMT, Fire-resistance, lab, Air diving, and so on

Send Inquiry Please bring the following description, we have more models to recommend to you!

| Technical Information | Your Kind Requirement |

| Capacity |

_________Nm³/h |

| Purity | _________% |

| Outlet Pressure | _________Mpa or Bar |

| Power | ________V/HZ |

Related Keywords