99% High Purity PSA Oxygen Plant

- Transportation:

- Ocean, Air, Land, Express, Others

Your message must be between 20 to 2000 characters

Contact Now| Incoterm: | FOB |

|---|---|

| Transportation: | Ocean,Air,Land,Express,Others |

99% High Purity PSA Oxygen Plant

This type of PSA Oxygen Generator produces oxygen quickly and has a high oxygen concentration. It is suitable for oxygen therapy and oxygen health care for various people, and has low power consumption.

The principle of the industrial oxygen generator is to use the air separation technology. First, the air is compressed at a high density and then the different condensation points of each component in the air are used. The gas and liquid are separated at a certain temperature, and then further rectified.

Principle:

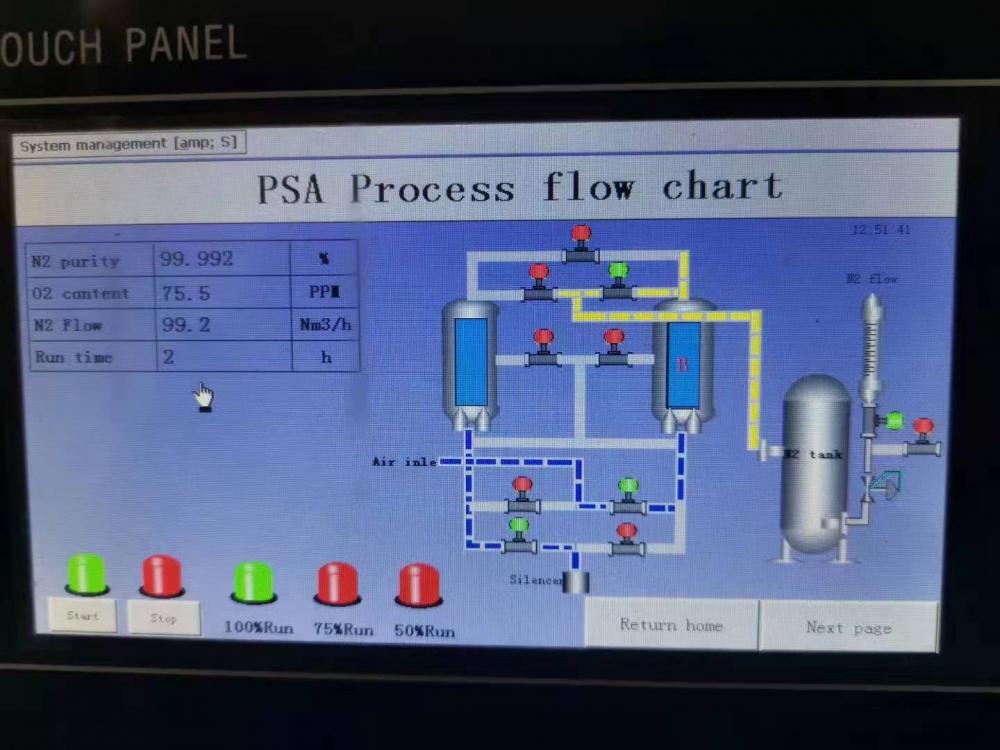

This process uses molecular sieves with capillary pores as adsorbents, and utilizes the difference in diffusion rate of oxygen molecule O2 and nitrogen molecule N2 in molecular sieve. Nitrogen and CO2 molecules in the air are absorbed into the pores, while most of the oxygen molecules O2 flow through the capillary pores into the oxygen collecting and storing tank in the later stage to be enriched. Molecular sieve has the characteristics of adding air pressure adsorption capacity increasing, and reducing air pressure adsorption capacity reducing, using this characteristic, the pressure swing adsorption method can be used to carry out continuous and uninterrupted oxygen and nitrogen separation. So as to achieve the preparation of 35%-95% purity room temperature oxygen. The PSA oxygen generator adopts a dual-tower parallel design. When tower A reaches saturation, it will switch to tower B for oxygen production through pressure equalization and other processes. At this time, tower A is vented and purged and regenerated, waiting for the next cycle of the oxygen generator; thus, double-tower alternate oxygen production is realized. In the latter stage of the oxygen collection process tank, high-purity continuous supply of oxygen is obtained, and finally the pressure is stabilized by adjusting the pressure and then transported to the gas point through the pipeline.

The main products of ROC: SMT Cleaning Machine, PSA Oxygen / Nitrogen generator, wafer cleaning equipment, PCBA Cleaning Machine, PCB Separator, SMT Spare Parts , Reflow / Wave Soldering Machine, SMT Nozzle, SMT Feeder etc. If there is any need, please contact us.

Oxygen production: 5 ~ 1000Nm3/h

Purity of oxygen: 93%±2%

Oxygen pressure: ≤3 bar(Adjustable)

Dew point: ≤-40ºC(Adjustable)

| Model | O2 Cpacity(Nm3/h) | Purity |

| HO2005 | 5 | 93%±2% |

| HO2010 | 10 | 93%±2% |

| HO2020 | 20 | 93%±2% |

| HO2040 | 40 | 93%±2% |

| HO2050 | 50 | 93%±2% |

| HO2080 | 80 | 93%±2% |

| HO2100 | 100 | 93%±2% |

| HO2150 | 150 | 93%±2% |

| HO2200 | 200 | 93%±2% |

Related Keywords