Containerized Medical Oxygen with Bottle Filling System

- Min. Order:

- 1 Others

- Min. Order:

- 1 Others

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Supply Ability: | strong |

| Payment Type: | T/T |

| Incoterm: | FOB,EXW |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

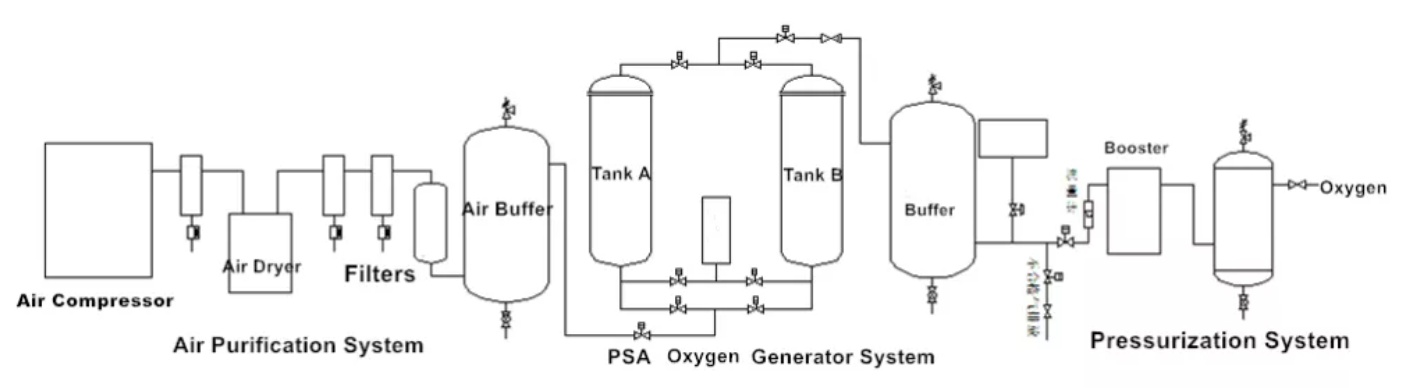

Pressure swing adsorption oxygen generator (also known as PSA oxygen generator), under the condition of normal temperature and pressure, uses PSA molecular sieve to selectively adsorb impurities such as nitrogen, carbon dioxide and water in the air, so as to obtain oxygen with high purity (93% ). Since the PSA Oxygen Plant entered industrialization, the technology has developed rapidly. Because of its price-performance ratio, it has strong competitiveness in the low-to-medium output range and the occasions where the purity requirements are not too high, so it is widely used in steelmaking fluxing , blast furnace oxygen enrichment, pulp bleaching, glass furnace, wastewater treatment and other fields.

High-efficiency, energy-saving and convenient PSA Oxygen Generator System,Microcomputer joint control intelligent gas solution, through the optimization of process design, the connection of valves and pipelines, effectively reduces gas loss and improves the utilization rate of air compressors.

The maintenance of the Gas Production Equipment in the oxygen generation system mainly includes the maintenance of air compressors, cold dryers, filters, and oxygen generators.

1. The daily maintenance of the air compressor is mainly to check whether the sewage outlet of the air compressor air storage tank is blocked and whether there is any obstruction at the cooling hole;

2. The radiator of the cold dryer should be cleaned frequently;

3. The sewage outlet of the filter should be checked frequently for blockage;

4. The exhaust port of the muffler of the oxygen generator should be checked frequently to see if it is unblocked.

Related Keywords