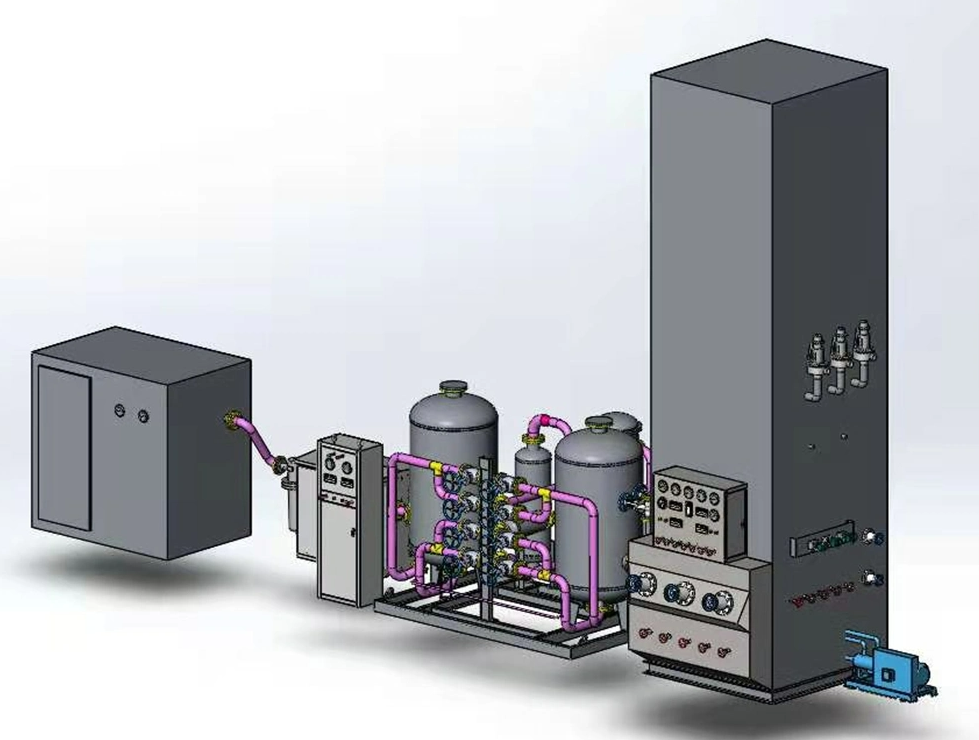

Cryogenic Medical Oxygen Plant

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

Product Description

The air separation plant is a device that uses air as raw material, turns the air into a liquid state through a compression cycle deep freezing method, and then gradually separates it from the liquid air through rectification to produce inert gases such as oxygen, nitrogen, and argon.

Liquid Oxygen System

The air separation plant is a large complex system, mainly composed of the following subsystems: power system, purification system, refrigeration system, heat exchange system, rectification system, product delivery system, liquid storage system and control system, etc.

Main Features of Air Separation Unit Air Liquide

1. The overall skid-mounted direct connection structure and high pressure hose connection make it unnecessary for users to invest in connecting pipelines and valves between devices, saving your investment cost.

2. The user only needs to make the equipment workshop and the ground and lifting tools in the workshop, without preparing other installation materials and tools.

3. Small size and low footprint.

4. The whole set of equipment has no foundation installation, stable operation, simple operation and convenient maintenance.

5. Since the equipment adopts internal compression process, the maintenance cost in the later period of the equipment can be minimized to improve the work efficiency.

6. All the single use of the most advanced technology, greatly reduce the energy consumption, save the electricity bill.

7. The cooling mode of the equipment is air cooling, so users do not need to build cooling pools, thus saving capital

expenditure.

8. The equipment installation and debugging period is short, and all the work can be completed in about one month.

9. At present, the equipment has been sold to Syria, Sudan, Nigeria and other countries.

10. The oxygen equipment produced by our company is sold to more than 40 countries and regions, and the installation and debugging personnel have rich experience in overseas installation.

Welcome to inquire for more asu plant information.

|

Technical information |

Your kind requirement |

| Capacity |

________Nm³/h |

| Purity |

_________% |

| Outlet pressure |

_________Mpa or Bar |

| Power |

________V/HZ |

Related Keywords