Medical Oxygen Cryogenic ASU Liquid Oxygen

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

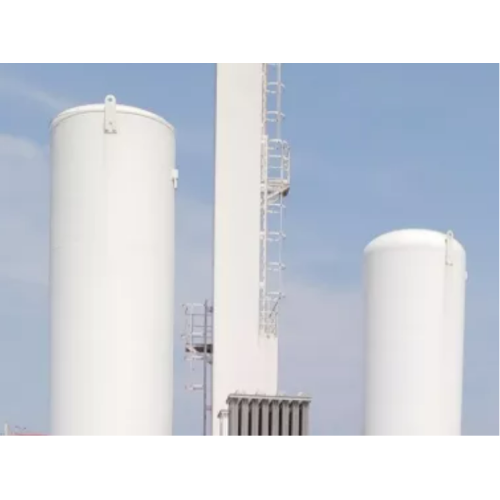

Cryogenic air separation plants processes rely on differences in boiling points to separate and purify products. The basic process was commercialized early in the 20th century. Since then, numerous process configuration variations have emerged, driven by the desire to produce particular gas products and product mixes as efficiently as possible at various required levels of purity and pressure. These air separation process cycles have evolved in parallel with advances in compression machinery, heat exchangers, distillation technology and gas expander technology.

All cryogenic processes include these steps:

Cryogenic processes are the most cost effective separation process for producing at high production rates and are capable of making the highest purity products.

The portions of the cryogenic air separation process that operate at very low temperatures (the distillation columns, heat exchangers and cold interconnecting piping sections) must be well insulated to minimize energy consumption and avoid operating problems. To accomplish this, these components are located inside insulated, sealed (and nitrogen purged) structures called "cold boxes”. Cold boxes may have a rectangular or round footprint and, depending on plant type and capacity, may measure approximately 2 to 4 meters on each side and have a height of 15 to 60 meters. Cold box as follow,

The basic principle of air separation plants is use cryogenic rectification to condense air into liquid and separate the air according to the evaporation temperature of each component. The two-stage rectification tower simultaneously obtains pure nitrogen and pure oxygen at the top and bottom of the upper tower. It is also possible to take out liquid oxygen and liquid nitrogen from the evaporation side and the condensation side of the main cooling respectively. The air separation in the rectification tower is divided into two stages, air is separated for the first time in the lower tower to obtain liquid nitrogen and at the same time obtain oxygen- enriched liquid air. The oxygen- enriched liquid air is sent to the upper tower for rectification to obtain pure oxygen and pure nitrogen. The upper tower is divided into two sections: with the liquid- air inlet as the boundary. the upper part is the rectification section, which rectifies the rising gas, recovers the oxygen component, and purifies the nitrogen purity, and the lower section is the stripping section to remove nitrogen components in the liquid, separated to improve the oxygen purity of the liquid.

KunPeng has Air Separation Plants, Liquid Oxygen / Nitrogen Plant, PSA Oxygen/Nitrogen Generator, VPSA Oxygen / Nitrogen Generator, and so on. If there is any need, feel free to contact us.

Specifications Classification

|

Product Name

|

Cryogenic air separation plants

|

Oxygen Purity

|

≥99.6%

|

|

|

Production

|

50Nm³/h—5000Nm³/h

|

Nitrogen Purity

|

≥99.99%

|

|

|

Brand

|

KunPeng

|

Model

|

KDONAR

|

|

|

Main Part

|

Air compressor system, Pre-cooling System, Air Purification System, Fractionating Column System, Turbo Expander System, Filling System, Instrument and Electric Control System

|

|||

|

Application Field

|

Medical & Industrial & Animal husbandry & Defense

|

|||

|

No

|

MAIN PART

|

FUNCTION

|

||

|

1

|

Air Compression System

|

Air be compressed to 0.5-0.7 Mpa by air compressor, Imported centrifugal air compressor, high efficiency, low consumption, stable and reliable operation

|

||

|

2

|

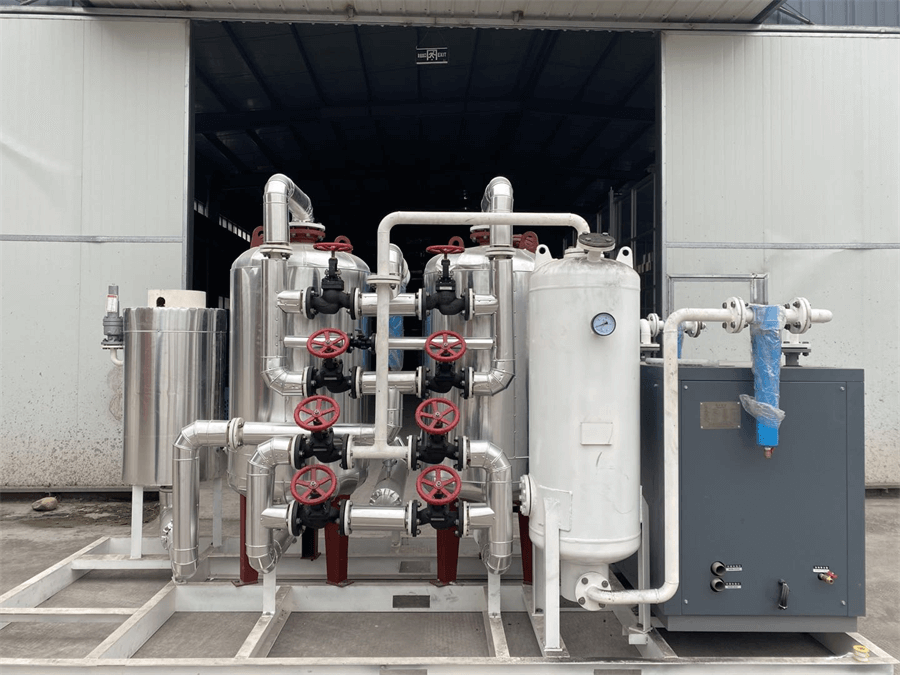

Pre-cooling System

|

The air is pre-cooled to 5-10℃ in the pre-cooling unit, and the moisture is separated. The original imported screw refrigeration compressor and the air-conditioning unit combined with all imported refrigeration components are equipped with a water separator, manual and imported automatic drains to drain water regularly.

|

||

|

3

|

Air Purification System

|

Removing the remained moisture, carbon dioxide and hydrocarbons of compressed air in the molecular sieve purifier. The purifier adopts a vertical single-layer bed with simple and reliable structure and low resistance loss; built-in filter, blowing off and purifier regeneration at the same time; high-efficiency electric heater ensures complete regeneration of molecular sieve

|

||

|

4

|

Fractionating Column System (Cold Box)

|

The heating, cooling, liquid accumulation and purification of the fractionating tower can be completed in one way, and the operation is simple, quick and easy. Adopt aluminum plate-fin heat exchanger, aluminum convection sieve plate tower, the entire fractionating tower equipment pipeline adopts argon arc welding, the tower body and main pipeline in the cold box are made of high-strength aluminum alloy or stainless steel to increase the strength , Reduce the torsion damage of the pipeline. The equipment brackets, pipes and valve brackets in the cold box shall be made of stainless steel or aluminum alloy. The cold box is insulated with pearl sand and slag wool to ensure that the loss of cold capacity is minimized. The cold box structure guarantees the overall strength and the requirements of anti-seismic and wind resistance, and guarantees the load-bearing capacity of the cold box. When the cold box is running, it is equipped with airtight protection and safety devices. The main equipment in the cold box is equipped with electrostatic grounding. The cold valve and pipeline in the cold box all connections are welded, and flange connections are avoided.

|

||

|

5

|

Turbo Expander System

|

The air expands and cools in the turbo expander and provides the cooling capacity required by the device.The turbo expander adopts gas bearing, which is simple and reliable, easy to operate, and high efficiency. The cold box of the expander is set separately for easy maintenance.

|

||

|

6

|

Heat Exchange System

|

The air exchanges heat with the refluxing oxygen, nitrogen, and dirty nitrogen in the heat exchanger of the fractionation tower, and is cooled close to the liquefaction temperature, and the refluxed oxygen, nitrogen, and dirty nitrogen are repeatedly heat exchanged to the ambient temperature;

|

||

|

6

|

Filling System

|

Single gas production: Internal compression process ( Cryogenic liquid pump, High pressure vaporizer, Filling manifold).

Multi-gas production: External compression process (Oxygen & nitrogen & argon booster, Filling manifold).

|

||

|

7

|

Instrument and Electric Control System

|

Siemens imported brand, Fully automatic production system, Digital control system

|

||

|

8

|

Others

|

Equipment layout drawing (according to civil engineering design), Process pipe design drawings, Instrument electrical design drawings, etc.

|

||

Cryogenic air separation plants is widely used, and different application scenarios have specific requirements for flow, purity, pressure, dew point and other parameters. In order to make your shopping experience happy, please leave your demand information, we will let professional engineers contact you, design specific technical solutions.

|

Technical information |

Your kind requirement |

| Capacity |

________Nm³/h |

| Purity |

_________% |

| Outlet pressure |

_________Mpa or Bar |

| Power |

________V/HZ |

Related Keywords