Cryogenic Liquid Air Separation Plant

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T,Paypal,Others |

|---|---|

| Incoterm: | FOB,CIF,EXW |

| Transportation: | Ocean |

Cryogenic Liquid Air Separation Plant

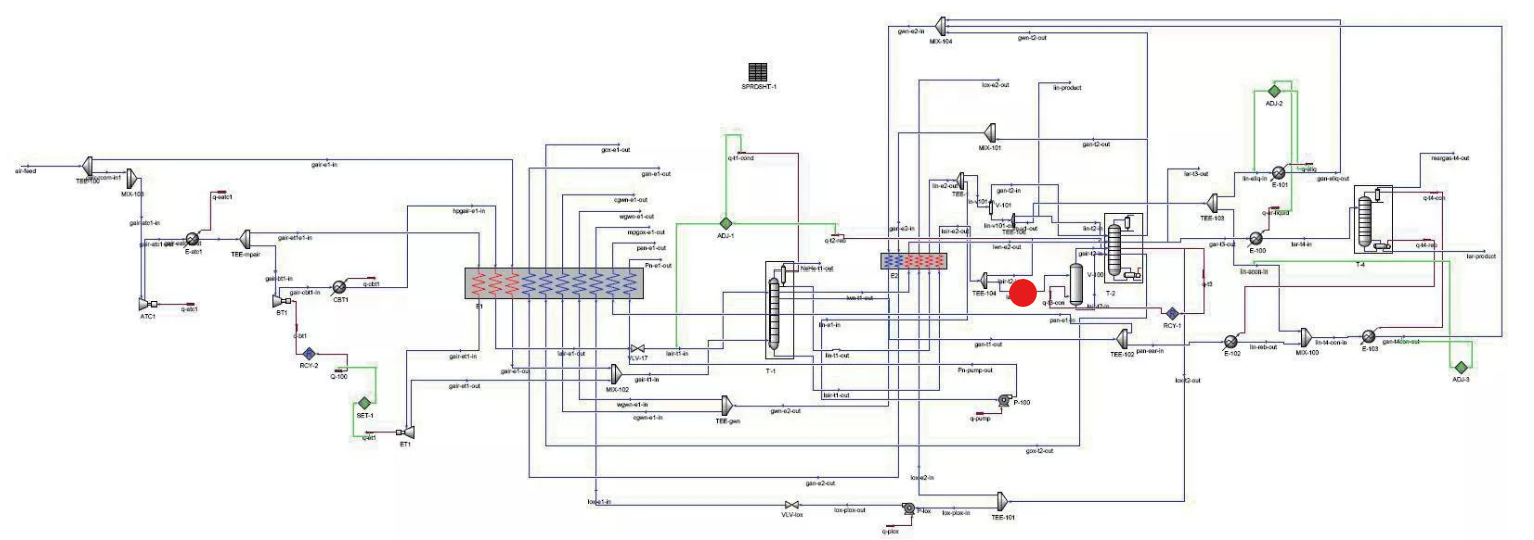

Principle

The basic principle of air separation is use cryogenic rectification to condense air into liquid and separate the air according to the evaporation temperature of each component. The two-stage rectification tower simultaneously obtains pure nitrogen and pure oxygen at the top and bottom of the upper tower. It is also possible to take out liquid oxygen and liquid nitrogen from the evaporation side and the condensation side of the main cooling respectively. The air separation in the rectification tower is divided into two stages, air is separated for the first time in the lower tower to obtain liquid nitrogen and at the same time obtain oxygen-enriched liquid air. The oxygen-enriched liquid air is sent to the upper tower for rectification to obtain pure oxygen and pure nitrogen. The upper tower is divided into two sections: with the liquid-air inlet as the boundary, the upper part is the rectification section, which rectifies the rising gas, recovers the oxygen component, and purifies the nitrogen purity, and the lower section is the stripping section to remove the nitrogen components in the liquid, separated to improve the oxygen purity of the liquid.

Security technology

* Reliable instrument tube protection system

* Pipes are designed along the tower body

* Pipe design along the tower body main condensation evaporator safety design

* Safety setting of oxygen valve

* Molecular sieve anti-punch technology

* Selection and layout of throttle valve

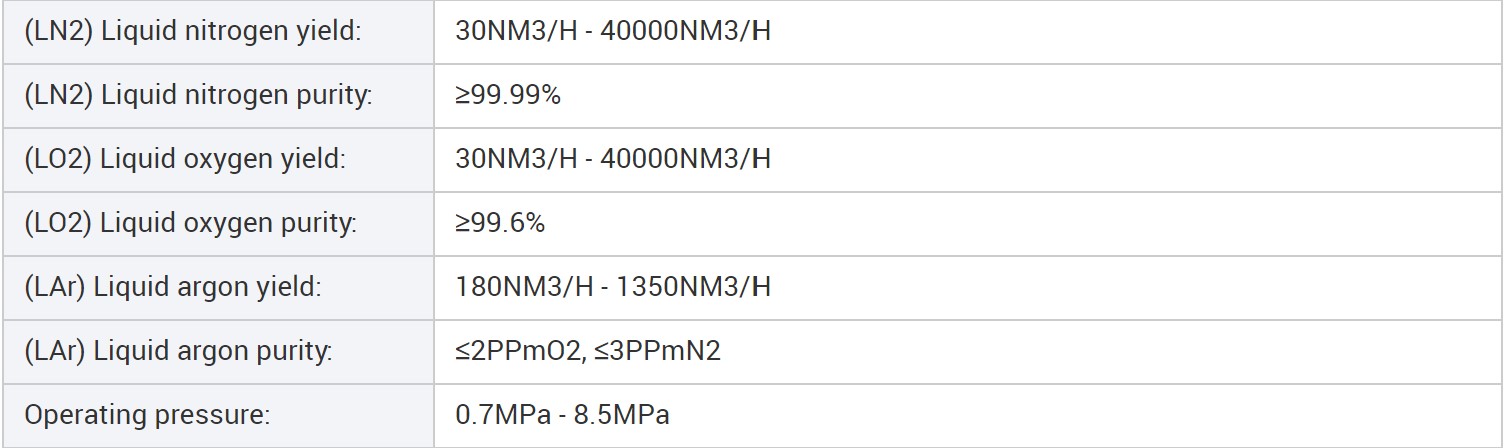

Technical parameter

|

1. Q: Can you provide the drawings of your plant/tanks? |

|

Normally, our drawings will be provided to our customer only after the order is confirmed. However, we can provide you some drawings which belong to our old customers for reference. By the way, here, I need to remind you that our company only provides the engineering design drawings and the civil design drawings will be out of our range. Because every place has different situation, your side needs to find civil design company in your local market to do the drawings according to your specified environment. |

|

2. Q: How’s the producing time and delivery time?? |

|

Normally, our production time is 6 months for air separation plants but it also depends on the capacity you require. The

bigger the plant, the longer time for production. Please also note that when the plant is finished, we need to wait for bulk vessel. It’s very common to wait for one or two months to find the right vessel.

The delivery date is 3-5 months.

|

|

3. Q: What about warranty? |

|

Equipment warranty is 12 months from the date on which the equipment is applied successfully into operation, or 14 months from the date on which the equipment has been delivered, whichever comes first.

Generally speaking, our air separation unit can work normally for 15-20 years if it is maintained properly. As a leading brand in China with over 40 years history, reliability and stability of our ASU is much better than small young companies.

|

Related Keywords