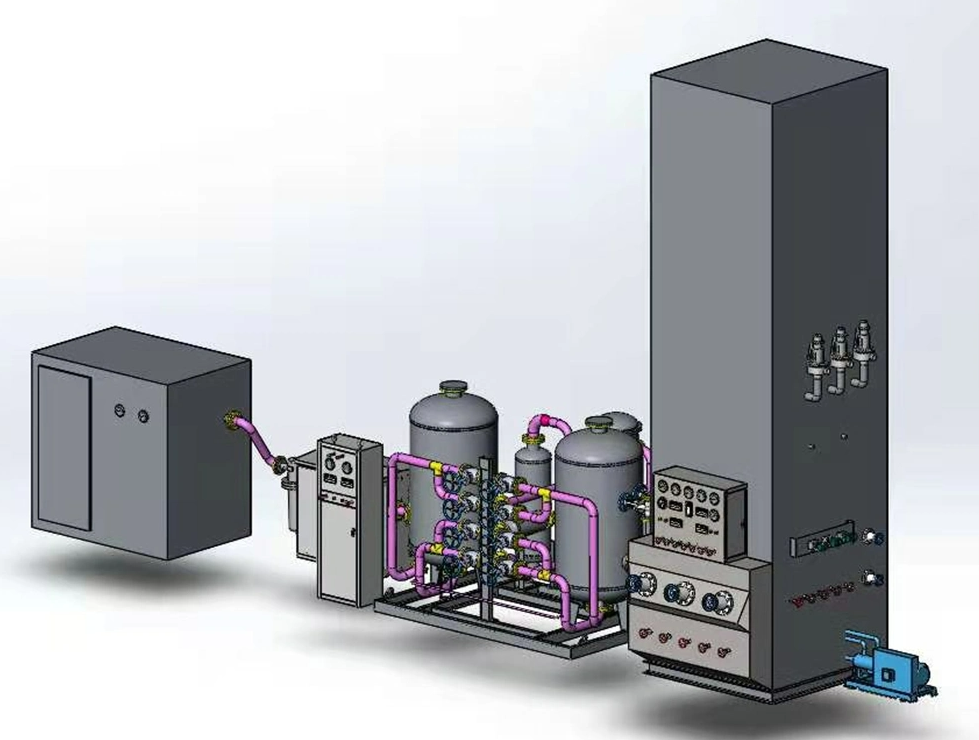

Air Separation Plants For Oxygen Nitrogen Argon Production

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai |

Process Description

( Oxygen Production Equipment / Nitrogen Production Equipment)The feed air is sucked into the self-cleaning air filter through the suction port to remove dust and mechanical impurities and then passes into the centrifugal air compressor. After being compressed, the feed air flows into the air cooler in the air pre-cooling unit to be cooled by refrigerant. The air from the pre-cooling system enters the purification system to get rid of moisture, carbon dioxide, and hydrocarbons. A portion of the clean air from the purification system enters the main heat exchanger in the cold box and is cooled by the return gas. The air cooled to be certain temperature enters the bottom of the lower column for the first rectification.

In the rectification column, the rising gas and the descending liquid contact are full for heat and mass transfer, so the nitrogen content in the rising gas increases gradually. The pure nitrogen passes into the main condenser evaporator mounted on top of the lower column for condensation. When the gaseous nitrogen is being condensed, the liquid oxygen in the condenser is evaporated. The liquid air and liquid nitrogen generated in the lower column enter the upper column as reflux after sub-cooling and throttling. In the upper column after further rectification, product gas oxygen, product gas nitrogen, waste nitrogen, and product liquid oxygen are obtained.

1. Safety Filtration System

Extensive design and construction experience, including Air Liquide's best-in-class safety standards, and feedback from the operations team ensure high reliability and safety performance.

2. Advanced Cryogenic Process Design

3. Pressure and Flow Control Capacity:

Up to 1000 tons per day. Reliable Valve Control and Stable SIEMENS PLC Control System. Optimized plant design depends on specific projects' economics, geography, products, specifications, energy costs, and customer process integration potentials.

(Cryogenic Air Separation Oxygen And Nitrogen Argon Plant)The basic principle of air separation is to use cryogenic rectification to condense air into liquid and separate the air according to the evaporation temperature of each component. The two-stage rectification tower simultaneously obtains pure nitrogen and pure oxygen at the top and bottom of the upper tower. It is also possible to take out liquid oxygen and liquid nitrogen from the evaporation side and the condensation side of the main cooling respectively. The air separation in the rectification tower is divided into two stages, air is separated for the first time in the lower tower to obtain liquid nitrogen and at the same time obtain oxygen-enriched liquid air. The oxygen-enriched liquid air is sent to the upper tower for rectification to obtain pure oxygen and pure nitrogen. The upper tower is divided into two sections: with the liquid-air inlet as the boundary, the upper part is the rectification section, which rectifies the rising gas, recovers the oxygen component, and purifies the nitrogen purity, and the lower section is the stripping section to remove the nitrogen components in the liquid, separated to improve the oxygen purity of the liquid.

Specification

|

(LO2) Liquid oxygen capacity:

|

30NM3/H - 40000NM3/H

|

|||

|

(LO2) Liquid oxygen purity range:

|

≥99.6%

|

|||

|

(LN2) Liquid nitrogen capacity:

|

30NM3/H - 40000NM3/H

|

|||

|

(LN2) Liquid nitrogen purity range:

|

≥99.99%

|

|||

|

(LAr) Liquid argon capacity:

|

30NM3/H - 1350NM3/H

|

|||

|

(LAr) Liquid argon purity range:

|

≤2PPmO2, ≤3PPmN2

|

|||

|

Medium Operating Pressure:

|

0.1MPa - 8.5MPa

|

|||

KunPeng company mainly deals with equipment, small PSA liquid nitrogen generators, PSA oxygen/nitrogen generators, air separation plants, and liquid oxygen/nitrogen generators, if you have any need, welcome to contact us, thank you.

Related Keywords