24BYJ48 Precision Stepper Motor

Your message must be between 20 to 2000 characters

Contact NowGear reduction motor is a component of a gear reducer and a motor. This type of component is also commonly referred to as a gearbox motor or a geared motor. It is usually assembled and assembled by a professional reducer manufacturer.

Gear reduction motors are widely used in automatic mechanical equipment, especially in packaging machinery, printing machinery, corrugated machinery, color box machinery, conveying machinery, food machinery, three-dimensional parking equipment, automatic storage, three-dimensional warehouse, chemical, textile, dyeing and finishing equipment, etc. Micro gear reduction motors are also widely used in the fields of electronic locks, optical equipment, precision instruments and financial equipment.

24BYJ48-527 Reduction Stepper Motor Parameters

| MODEL | ITEMS | SPEC |

| 24BYJ48-527 |

Rated Voltage |

5VDC |

Phase |

4 |

|

Reduction Ratio |

1/32 |

|

Steo Angle |

5.625° |

|

Exciting Method |

1-2 |

|

Direct-current Resistance |

20Ω±10%(25°C) |

|

No-load pull-in Frequency |

≥500Hz |

|

No-load pull-out Frequency |

≥1000Hz |

|

pull-in Torque |

≥40mN.m(5VDC.800Hz) |

|

Detent Torque |

≥30mN.m |

|

Insulation Resistance |

≥50M Ω 500VDC |

|

Dielectric Strenght |

600VAC |

|

Insulation Class |

B |

|

Noise |

≤40dB |

|

Friction Torque |

60-294mN.m |

|

Terminal Sec |

5P*1.5 |

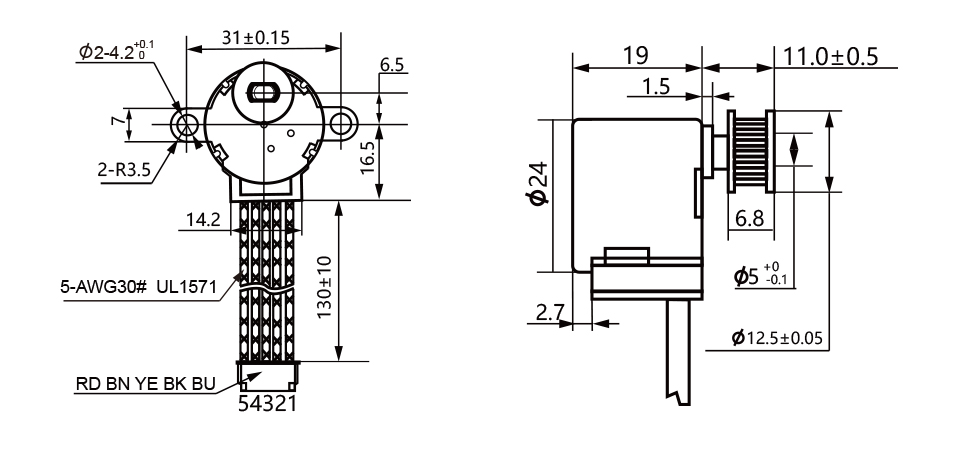

Drawing of 24BYJ48-527 Reduction Stepper Motor

Applications of Stepper Motor

• 3D printing equipment

• Barrier gate

• Printing presses

• Automatic toilet seat cover

• Electric tailgate

• Nano sprayer

• Vending machines

• Aircraft – In the aircraft industry, stepper motors are used in aircraft instrumentations, antenna and sensing applications, and equipment scanning

• Automotive – The automotive industry implements stepper motors for applications concerning cruise control, sensing devices, and cameras. The military also utilizes stepper motors in their application of positioning antennas

• Chemical – The chemical industry makes use of stepper motors for mixing and sampling of materials. They also utilize stepper motor controllers with single and multi-axis stepper motors for equipment testing

• Consumer Electronics and Office Equipment – In the consumer electronics industry, stepper motors are widely used in digital cameras for focus and zoom functionality features. In office equipment, stepper motors are implemented in PC-based scanning equipment, data storage drives, optical disk drive driving mechanisms, printers, and scanners

• Gaming – In the gaming industry, stepper motors are widely used in applications like slot and lottery machines, wheel spinners, and even card shufflers

• Industrial – In the industrial industry, stepper motors are used in automotive gauges, machine tooling with single and multi-axis stepper motor controllers, and retrofit kits which make use of stepper motor controllers as well. Stepper motors can also be found in CNC machine control

• Medical – In the medical industry, stepper motors are utilized in medical scanners, microscopic or nanoscopic motion control of automated devices, dispensing pumps, and chromatograph auto-injectors. Stepper motors are also found inside digital dental photography (X-RAY), fluid pumps, respirators, and blood analysis machinery, centrifuge

• Scientific Instruments –Scientific equipment implement stepper motors in the positioning of an observatory telescope, spectrographs, and centrifuge

• Surveillance Systems – Stepper motors are used in camera surveillance

【Industry Encyclopedia】

Stepper motor single-chip microcomputer control program command encyclopedia

The specific introduction of the 8279 chip is as follows:

1) DB0~DB7: Bidirectional data bus. 827 data and commands are transmitted in the CPU.

2) CLK: 8279 system clock, 100KHZ is the best choice.

3) RESET: Reset input line, high level is effective. When a high level appears at the RESET input, the 8279 is initially reset.

4) /CS: Chip selection signal. Low level enable, when enabled, you can write commands to 8279 or read 8279 data.

5) A0: Characteristics used to distinguish information. When A0=1, the CPU writes commands to 8279 or reads the state of 8279; when A0 is 0, reads and writes a data.

6) /RD: Read the control line. /RD=0.8279 will send data to the external bus.

7) /WR: Write control line. /WR=0.8279 will capture data from the external bus.

8) IRQ: Interrupt request output line, active at high level. When the FIFO RAM buffer contains the key code of the close key on the keyboard, the IRQ line goes up and an interrupt is requested to the CPU. When the CPU reads all the data of the input keys in the buffer, the interrupt request line drops to low Level.

9) L0~SL3: Scan output line, used to scan the keyboard display. It can be encoding mode (16 to 1) or decoding mode (4 to 1).

10) ~RL7: Feedback input line, which is pulled to high level by internal pull-up resistor, or it can be pulled to low level by keys on the keyboard.

11) FT, CNTL/STB: Control key input line, pulled to high level by internal pull-up resistor, or pulled to low level by external control key.

12) TB0~3, OUTA0~3: Display segment data output lines, which can be used as two nibbles output respectively, and can also be used as 8-bit segment data output ports. At this time, OUTB0 is the lowest bit and OUTA3 is the highest bit.

13) Blanking output line, active low. When the display is switched or the blanking command is used, the display will be blanked.

Single-chip stepper motor speed control program

The initialization procedure of 8279 is as follows:

INIT: MOV DPTR, #7FFFH; set 8279 command/status port address

MOV A, #0D1H; clear display command word

MOVX @DPTR, A; send clear display command

WEIT: MOVX A, @DPTR; read status

JB ACC.7.WEIT; wait for the end of the clear display RAM

MOV A, #34H; set the frequency division coefficient, crystal oscillator 12MHz

MOVX @DPTR, A; send frequency division coefficient

MOV A, #00H; set keyboard/display command

MOVX @DPTR, A; Send keyboard/display commands

MOV IE, #84H; Allow 8279 interrupt

RET

The display subroutine is as follows:

DIS: MOV DPTR, #7FFFH; set 8279 command/status port address

MOV R0.#30H; The first address of the field code

MOV R7.#08H; 8-digit display

MOV A, #90H; set to display the command word

MOVX @DPTR, A; send display command

MOV DPTR, #7FFEH; set the data port address

LP:MOV A, @R0; take display data

ADD A, #6; add offset

MOVC A, @A+PC; Look up the table, get the segment code of the data

MOVX @DPTR, A; send segment code display

INC R0; adjust the data pointer

DJNZ R7.LP;

RET

SEG: DB 3FH, 06H, 5BH, 4FH, 66H, 6DH

; character 0, 1, 2, 3, 4, 5 segment code

DB 7DH, 07H, 7EH, 6FH, 77H, 7CH

; character 6, 7, 8, 9, A, B segment code

DB 39H, 5EH, 79H, 71H, 73H, 3EH

; character C, d, E, F, P, U segment code

DB 76H, 38H, 40H, 6EH, FFH, 00H

; character H, L, -, Y, "empty" segment code

gear motor 永磁电机 brushless motor 电机厂家 深圳做网站公司 关键词排名优化 花灯制作 净水器加盟 宜宾净水器 泉州净水器批发 珠海净水器批发 天津净水器批发 重庆净水器批发 沈阳净水器批发 杭州净水器批发 汕头净水器批发 苏州净水器批发 温州净水器批发 宁波净水器批发 昆山净水器批发

Related Keywords