Panasonic Radial Lead Component Insertion Machine RL132

- Payment Type:

- T/T

- Incoterm:

- FOB, CFR, EXW

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Delivery Time:

- 7 Days

- Transportation:

- Ocean

- Port:

- Hong Kong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Japan |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB,CFR,EXW |

| Transportation: | Ocean |

| Port: | Hong Kong |

Features

The RL132 is a radial component insertion machine with guide pin system capable of high-speed insertion at a tact time of 0.14 s/component,

which also results in saving energy and reduced operation noise.

1.High-speed and High-density Insertion

High-speed insertion at a maximum tact time of 0.14 s/component allows higher-density insertion.

2.Improved Operation Rate

•The fixed component feeder provides components without stopping the machine which allows longer hour operation.

•Auto supply recovery function and the programming features also contribute to longer hour operation of the machine.

3.Higher Reliability

Insertion positions are corrected based on the offset obtained through visual recognition of insertion holes on PC board, ensuring highly reliable insertion.

Machine Specifications

| Model ID | RL132 | ||

| Model No. | NM-EJR5A | NM-EJR6A | |

| PCB dimensions (mm) | L 50 x W 50 to L 508 x W 381 | ||

| Max.speed | 0.14 s/component | ||

| No.of component inputs | 40 | 80 (Connection mode), 40 + 40 (Exchange mode) | |

| Applicable components |

Pitch 2.5/5.0 mm (standard), 7.5 mm and 10 mm (option), Resistor, Electrolytic capacitor, Ceramic capacitor, LED, Transistor, Filter, Resistor network |

||

| PCB exchange time | about 2 s to about 4 s (Room temperature 20 °C) | ||

| Insertion direction | 360°direction by 1°increment | ||

|

Electric source *1 |

3-phase AC 200 V, 3.5 kVA | ||

| Pneumatic source | 0.5 MPa, 80 L/min (A.N.R.) | ||

| Dimensions (mm) | W 2 104 x D 2 183 x H 1 575 *2 | W 3 200 x D 2 417 x H 1 575 *2 | |

|

Mass *3 |

1750 kg | 2350 kg | |

Item

Details

Power supply

• Rated voltage 3-phase 200 / 220 V ± 10 V selectable

380 / 400 / 420 / 480 V ±20 V selectable

• Frequency 50 / 60 Hz

• Rated capacity Approx. 3.5kVA

Air supply

• Supplied air pressure Min. 0.45 MPa to Max. 0.8 MPa

(Operation air pressure: 0.45 ~ 0.5 MPa)

• Supplied air mass Approx. 80 L / min. (A.N.R)

Note: Quick coupler attached (SMC KK13P-03M, KK13S-03F).

Dimensions

• NM-EJR5A W2,104 x D2,183 x H1,575 mm

(Not including signal tower)

• NM-EJR6A W3,200 x D2,417 x H1,575 mm

(Not including signal tower)

Mass

• NM-EJR5A Approx. 1,750 kg (main body only)

• NM-EJR6A Approx. 2,350 kg (main body only)

Environmental requirements

• Ambient temperature 20°C ± 10°C

Operating controls

• Interactive operation via color LCD touch screen

English/Japanese/Chinese selectable with a single button Recognition screen

(displays the recognized board image on a superimposed window)

Hierarchical menu (Operator/Engineer)

• I /O functions SD card slot

(standard equipment)

• Communication LAN comunicaton (TCP/IP)

Coating color

• Standard color White: W-13 (G50)

Basic Performance

*1 X-Y table movement at the tact time of 0.14 s/point: Within 36 mm Insertion

direction: each 1degree (0°- 90°, 0°- (-)90° : 0.14 s/point)

*2 The tact time above is enabled only when components are continuousl

taped. (Tact time varies if there are missing portions.)

*5 Tact time varies also if 10 or more feeders are operated at a time due to the

NC data setting.

*6 Tact time must be set between 0.25 and 0.30 s when inserting components

more than 12 mm in diameter or more than 18 mm in height

Insertion pitch: 2.5 and 5.0 mm (standard), 7.5 and 10.0 mm (option)

Height: Hn = Max. 23 mm

Component pack must be lower than 360 mm and width less than 62 mm.

Component reel must be up to 360 mm in diameter and 62 mm in width.

Width-to-length ratio: Width should be equal to or less than length.

Consult us for boards having width longer than length.

Boards of thickness from 0.6 mm (min.) to 2.0 mm (max.) are applicable.

Even if the board thickness is within the above range, clinched angle of

the inserted lead or lead length may vary, or board transfer error may

occur depending on the shapes of board or insertion holes. Please contact

us in advance.

Item

Details

Insertion tact time

• Max. tact time: Approx. 0.14 s/point (0.17, 0.20, 0.25, 0.3 s/point changeable)

=REMARKS=

*4 Tact time varies when new components are inserted for recovery.

Applicable components

Resistors, electrolytic capacitors, ceramic capacitors, LEDs, transistors, filters and resistor networks

Component packaging

• Taping (in pack or reel)

=REMARKS=

PCB replacement time

• Approx. 2 second (Ambient temperature: 20°C):

=REMARKS=

PCB replacement time only includes time for loading. It takes approx. 4 to 5 seconds including the table return time.

Applicable PCB

• Dimensions

Min. 50 x 50 mm to Max. 508 x 381 mm

Min. 50 x 40 mm ~ Max. 508 x 371 mm

• Thickness

1.6 mm ± 0.15 mm (for standard specification)

=REMARKS=

Max. 1 kg per board including inserted components.

• Flow direction

Right to left (Standard) or Left to right (Option)

• Board positioning method

Pin positioning (Standard, without positioning in the Y direction),

=REMARKS=

Contact us separately for edge positioning.

Insertion pitch

• 2-pitch (standard), 3-pitch or 4-pitch (option)

2.5 mm and 5.0 mm (standard),

2.5 mm ,5.0 mm ,7.5 mm ,or 2.5 mm ,5.0 mm ,7.5 mm,10.0 mm (Option)

Insertion direction

• 360 degrees by 1 degree

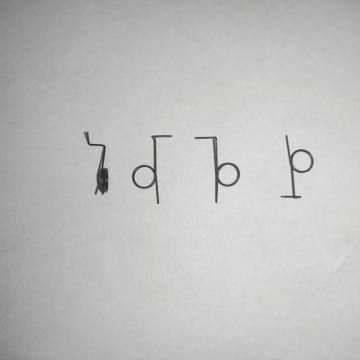

Anvil

• Cutting & Clinch type system (Piezoelectric detection system)

No. of component inputs

• NM-EJR5A 40 types

• NM-EJR6A 80 types

Control Specifications

Data from conventional RH series (RH, RH6, RHP, RHP2, RH2, RH3, RH5, RHSG, RHS,

RHS2, RHS2B, RHU, RHU2, RHUP, RG131 and RL131) can be directly used on the RL132.

Item

Details

Control system

• Microcomputer system

Programming method

• X-Y axes: Absolute coordinate commands

• Insertion pitch: Absolute commands

• Component feeder: Feeder number designation

Least command increment of X-Y table

• 0.01 mm / pulse

Program

• Number of NC programs

• Built-in flash memory 200 programs, 5000 steps / program

(Note: In case of programs involving pattern repeat, the total number

of steps after expanding the program must be less than 5,000.)

• SD card Depends on the card capacity. (up to 2 GB)

Indication light

• Signal tower (3 lamps, top to bottom: red/yellow/green)

Hole position offset

• Determines optimum insertion positions based on the recognition of all

insertion positions to make positional corrections (XY and q).

Self-diagnosis function

• Presents on the color LCD the machine status when the power is ON and

situation of any troubles occurred, as well as countermeasures against the

troubles.

Others

• Programming functions Pana

PRO J

PanaPROJ the software for optimizing the balance of line consisting of

multiple machines and for assigning data is available.

• Data compatibility

=REMARKS=

When restarting the machine after a long stop, check that there is nothing wrong with the machine operations in Manual mode and idle the machine.

Shenzhen Keith Electronic Equipment Co., Ltd." located in Baoan District, Shenzhen. It is a supplier of AI and SMT equipment, spare parts, consumables and auxiliary consumption materials in China. Over the years, we have provided advanced equipment and parts for our customers to ensure high-quality service. And for exporting market, we are planing to developing Europe, North America, South America, Southeast Asia,India and where need SMT equipment spare parts.

Business philosophy: cooperation, win-win, innovation, mutual assistance

We have been adhering to the brand management concept of "focusing on product quality and customer needs", through the implementation of open innovation, excellent operation management, human resources development and other strategies, to comprehensively construct the core competitiveness of the company, create customer and social values, and win the unanimous praise of the vast number of customers and society.

Main products:

Panasonic Insertion Machine, Panasonic Insertion Machine Parts, Panasonic Placement Machine, Panasonic Placement Machine Parts, Panasonic Feeder & Feeder Parts, Feeder Trolley, SMT Cutter etc. To learn more about our products, please contact us through the following email address, look forward to your cooperation!

Related Keywords