Energy Saving Dry Type Power Transformers

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Qingdao, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 SETS/ YEAR |

| Supply Ability: | 15000 SETS/ YEAR |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE,ISO 9001, ISO 14001, OHSAS 18001 |

| HS Code: | 85043400 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Qingdao,Shanghai |

Like g e dry type transformers, the super energy saving SC(B)10 series dry type power transformers produced by FGI are widely applied in service, in diverse industries including electricity boards, nuclear / thermal / hydel power plants, railway traction, high-rise buildings, hospitals, subways, underground vaults, tunnels, schools, steel factories, chemical plants, etc. where safety is of prime concern. The cast coil transformer is not equipped with the outer casing and is used indoors. If it is needed outdoors, it can be equipped with the outer casing and IP20 or IP23.

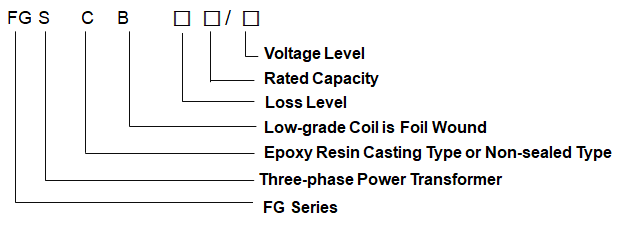

Product Model Description

Conditions of Use

- Type of device: Indoor type

- Normal environmental conditions: Altitude does not exceed 1000m

- Ambient temperature:

Maximum temperature: +40℃

Minimum temperature: -25℃( When -25 ℃, it requires on-load switch and temperature controller)

Relative Humidity: 100%

Maximum daily average temperature: +30℃

Maximum annual average temperature: +20℃

- The installation site should be clean and free of electric dust, no corrosive gas, and have good ventilation conditions. If installed in a basement or other poorly ventilated location, ventilation should be mandatory. This cast coil transformer requires approximately 3~4m3/min of ventilation per 1KW (no-load loss + load loss).

- When installing the cast resin current transformer, it should generally leave the wall and other obstacles 800mm. There should be a distance of 300mm between adjacent transformers. For distribution boxes and other installations where space is limited, the above distances can be adjusted appropriately.

-

Under normal circumstances, the cast resin dry type transformers can be placed directly in the use site, and the installation can be put into operation after the inspection is completed. For earthquake-proof and other special requirements, the base where the transformer is installed should be embedded with bolts and the transformers fixed by bolts and nuts.

Performance Features

1. Dry type transformers are safe, fire preventive, free of pollution and capable to be run directly in the load center.

2. Produced with the advanced technology, cast coil transformers feature high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability and long service life.

3. Dry distribution transformers feature low loss, low noise, obvious energy saving effect and are maintenance free.

4. Dry transformers feature good heat dissipation performance, strong over-load capacity and higher running capacity at forced air cooling.

5. Dry type distribution transformers feature good moisture-proof performance and suitable for high humidity and other harsh environments.

6. 3 phase dry type power transformers can be equipped with perfect temperature detecting and protection system. The intelligent signaling and temperature control system can automatically detect and display working temperature of three phase windings, automatically start and stop the fan and has the functions such as alarming and tripping.

7. cast resin dry type transformers feature small volume, light weight, small occupied space and low installation cost.

Technical Parameters

Rated Frequency: 50Hz

Cooling Method: 100~1000AN or according to customers needs

Enclosure Rating: IP20 or according to customers needs

Connection Group Label: Dynll or according to customers needs

Transformer Phase Sequence: The high pressure side is from left to right, the high pressure side is A, B, C, and the low pressure side is c,b,a. Winding Insulation Grade: F Level or according to customers needs

Insulation Level: 10KV grade power frequency withstand voltage 35KV, impact withstand voltage 75KV

20KV grade power frequency withstand voltage 55KV, impact withstand voltage 125KV

35KV grade power frequency withstand voltage 70KV, impact withstand voltage 170KV

Temperature Rise Limit: insulation system temperature is 155 ° C, the maximum temperature is 100K

Selection Guide

| Rated Capacity(kVA) | No-load Loss (W) | Load Loss @different insulation endurance classes | Short Circuit Impedance(%) | ||

| B(100%) | F(120℃) | H(145℃) | |||

| 30 | 190 | 670 | 710 | 760 | 4.0 |

| 50 | 270 | 940 | 1000 | 1070 | |

| 80 | 370 | 1290 | 1380 | 1480 | |

| 100 | 400 | 1480 | 1570 | 1690 | |

| 125 | 470 | 1740 | 1850 | 1980 | |

| 160 | 540 | 2000 | 2130 | 2280 | |

| 200 | 620 | 2370 | 2530 | 2710 | |

| 250 | 720 | 2590 | 2760 | 2960 | |

| 315 | 880 | 3270 | 3470 | 3730 | |

| 400 | 980 | 3750 | 3990 | 4280 | |

| 500 | 1160 | 4590 | 4880 | 5230 | |

| 630 | 1340 | 5530 | 5880 | 6290 | |

| 630 | 1300 | 5610 | 5960 | 6400 | 6.0 |

| 800 | 1520 | 6550 | 6960 | 7460 | |

| 1000 | 1770 | 7650 | 8130 | 8760 | |

| 1250 | 2090 | 9100 | 9690 | 10370 | |

| 1600 | 2450 | 11050 | 11730 | 12580 | |

| 2000 | 3050 | 13600 | 14450 | 15560 | |

| 2500 | 3600 | 16150 | 17170 | 18450 | |

| 1600 | 2450 | 12280 | 12960 | 13900 | 8.0 |

| 2000 | 3050 | 15020 | 15960 | 17110 | |

| 2500 | 3600 | 17760 | 18890 | 20290 | |

Product Series Description

1. Temperature Display, Temperature Control System

According to the user's requirements, the dry type transformers can be equipped with a temperature display and temperature control system. It acts as an overload warning signal and automatically displays the temperature. When the internal temperature of the coil exceeds the limit set by the signal thermometer, the fan can be started and stopped, the power supply is tripped, and the transformer is cut off.

2. Cooling System

The cooling method is self-cooling (AN). When self-cooling, the output capacity is 100%, and forced air circulation cooling (AF) can be overloaded for 25% for a long time and 50% for short-term overload.

3. Protection Level

The general protection level of the cast resin transformers is IP00, that is, the cast coil transformer is not equipped with the outer casing and is used indoors. If it is needed outdoors, it can be equipped with the outer casing and IP20 or IP23 (when the transformer protection level is high, the transformer derating operation should be considered). Note: The IP20 housing prevents solid foreign objects greater than 12mm from entering, providing a safety barrier to live parts. Based on the IP20, the IP23's protective case prevents water droplets from flowing within 60 degrees of the vertical line.

Factory Show

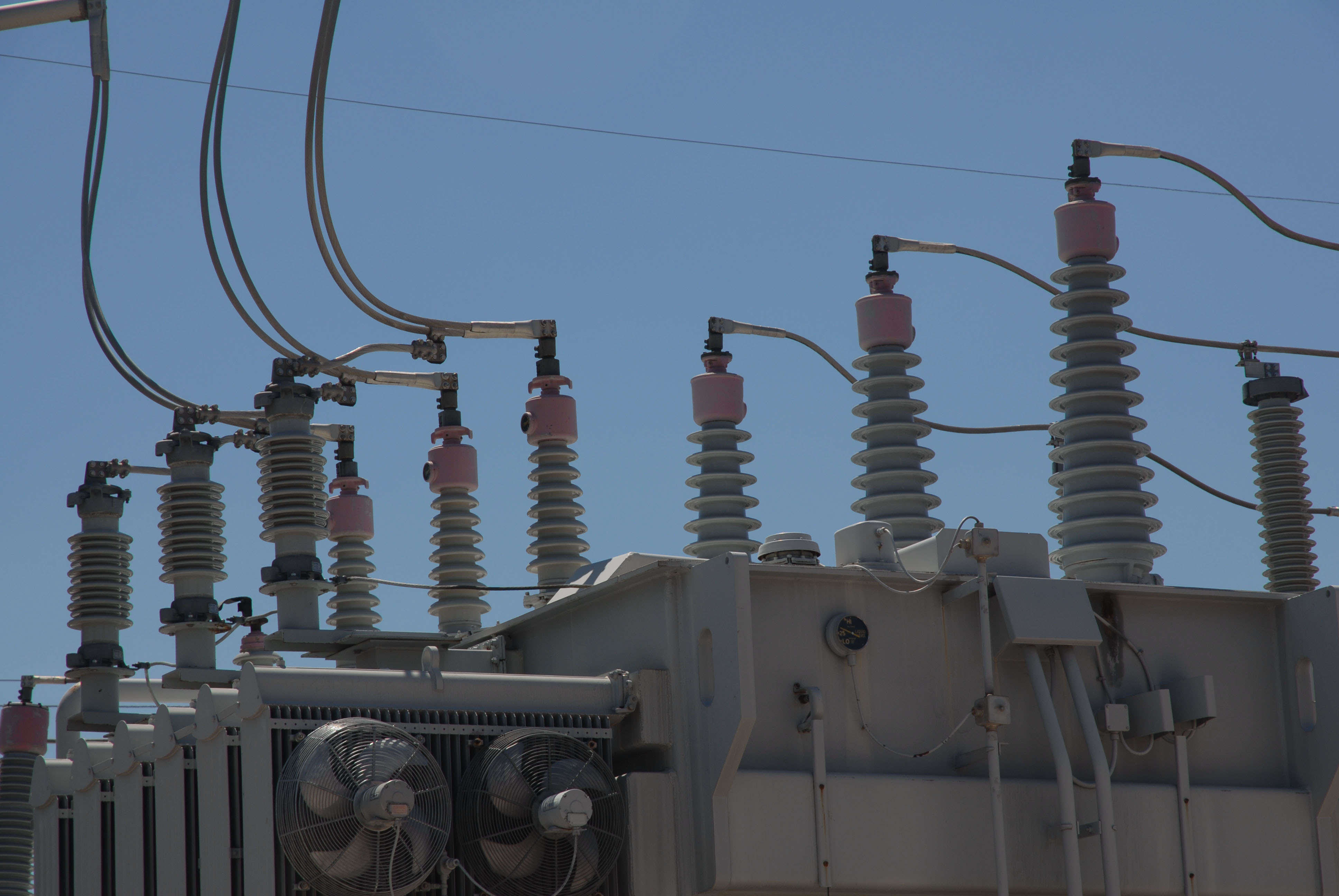

Application

In Service in diverse Industries, Electricity Boards, Nuclear / Thermal / Hydel Power Plants, Railway Traction, High-Rise Buildings, Hospitals, Subways, Underground Vaults, Tunnels, Schools, Steel Factories, Chemical Plants, etc. Where safety is of prime concern.

Quality Environmental Certification

Our Service

OEM Service is available

After-sales responding within 24 hours

One to one pre-sales consulting services

We are factory with high-tech professional engineer teams

Technician could be assigned to go abroad to carry out site commissioning and technical training

Related Keywords