Platinum Cure Molding Rubber Silicone RTV

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 200 Kilogram

- Min. Order:

- 200 Kilogram

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

Platinum Cure Molding Rubber Silicone RTV

Strenghts for platinum cure molding rubber silicone rtv

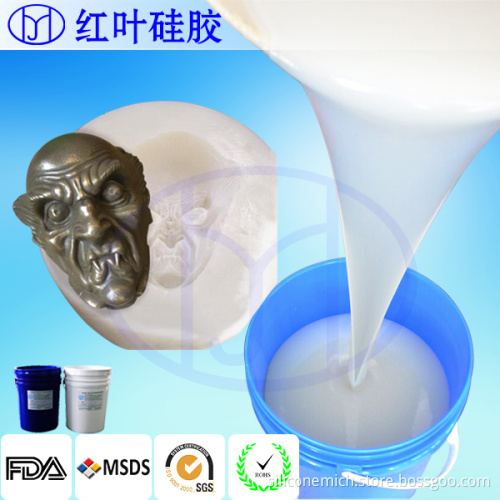

Platinum cure molding rubber silicone rtv is used for prototyping and the reproduction of parts. Silicone moulds can be constructed in many different forms depending on the shape of the part you are making. In this section we will outline how to create the easiest one part flat back mould.

Features of platinum cure molding rubber silicone rtv

1. Good characteristics of easy-operation

2. Light viscosity and good flowability

3. Low shrinkage

4. Favorable tension

5. No deformation

6. Favorable hardness

7. High temperature resistance, acid and alkali-resistance and ageing resistance

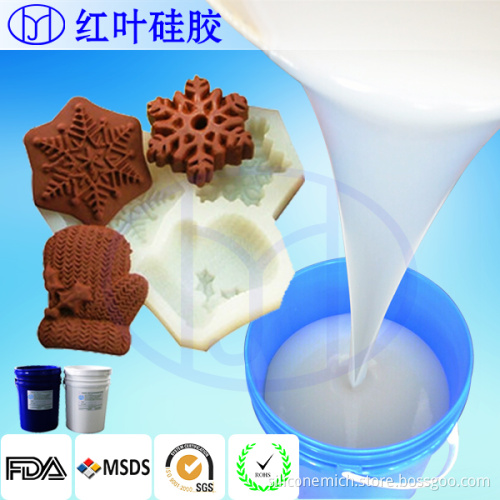

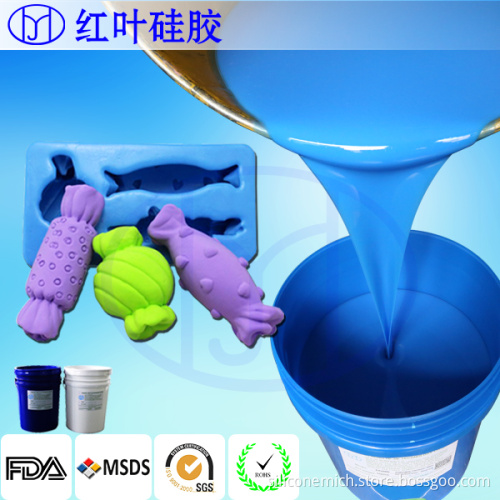

8. Food grade, non-toxic

Datasheet of platinum cure molding rubber silicone rtv

|

Model |

Color |

Mixing ratio |

Pot life (mins) |

Demouled time (hrs) |

Hardness(A0) |

Tensile-strength (kgf/cm2) |

Tear-strength (kgf/cm) |

Viscosity (cps) |

Elongation (%) |

|

HY-E625 |

translucent |

1 : 1 |

30-60 |

4±1 |

25±2 |

35±2 |

25±2 |

6000±3000 |

≥400 |

|

HY-E630 |

translucent |

1 : 1 |

30-60 |

4±1 |

30±2 |

40±2 |

23±2 |

7000±3000 |

≥395 |

|

HY-E635 |

translucent |

1 : 1 |

30-60 |

4±1 |

35±2 |

47±2 |

22±2 |

8000±3000 |

≥470 |

PROCESSING RECOMMENDATIONS

1. polishing the original model

2. Fixing the original model,and then apply the release agent to brush the model equably.

3. Weighing and mixturing:The percentage of A and B is 10:1 or 1:1, and then mixing and stirring

4. The treatment of degassing by vacuumizer(the lasting-time is suggested to be about 2~3minutes no more than 8~10minutes)

5. Pouring the treated silicone into mould fram

6. After 3~5hours later,the mould will be finished

Package:20kg or 200kg /drum.

Self-life:24 months

Price:10-15usd/kg(contact me for details)

Specific parameters, price and delivery details, etc. welcome to call!

If you are interested in our production, or any questions of our production , pls feel free to contact us by email!

Michael

Email:hyhl(at)szrl.net

Tele:+8618938867553

Wechat:hl869293137

Skype:hyhl(at)szrl.net

Facebook:18938867553

Whatsapp:+8618938867553

Related Keywords