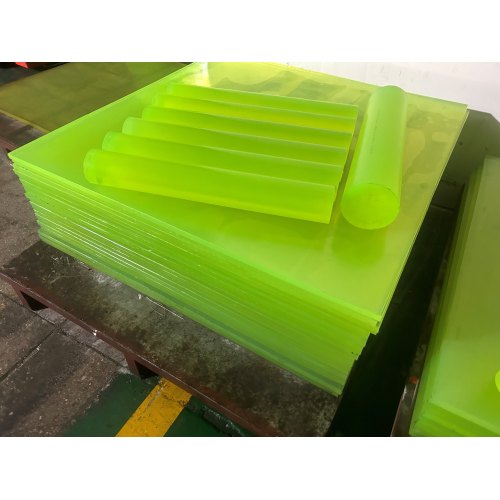

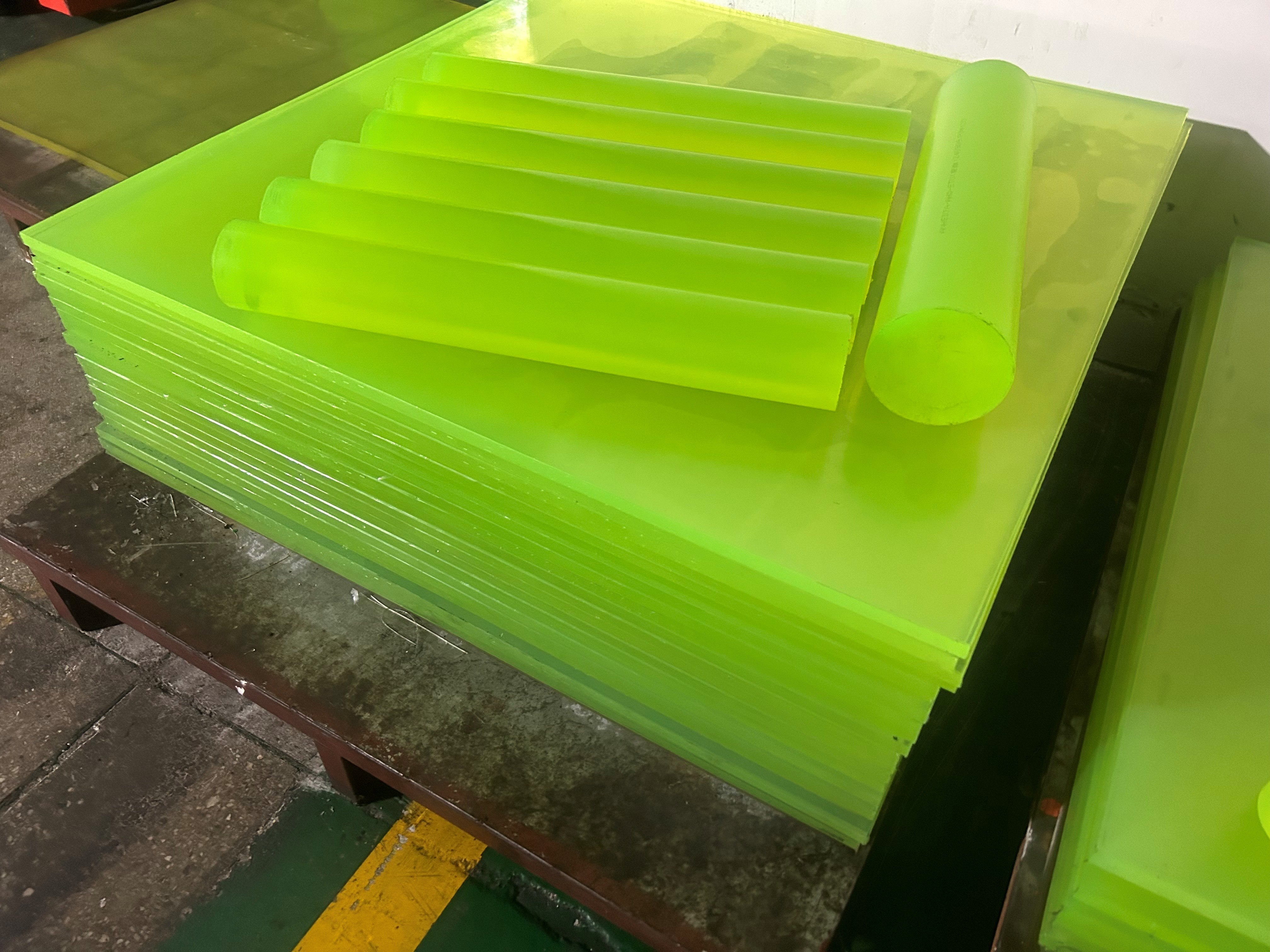

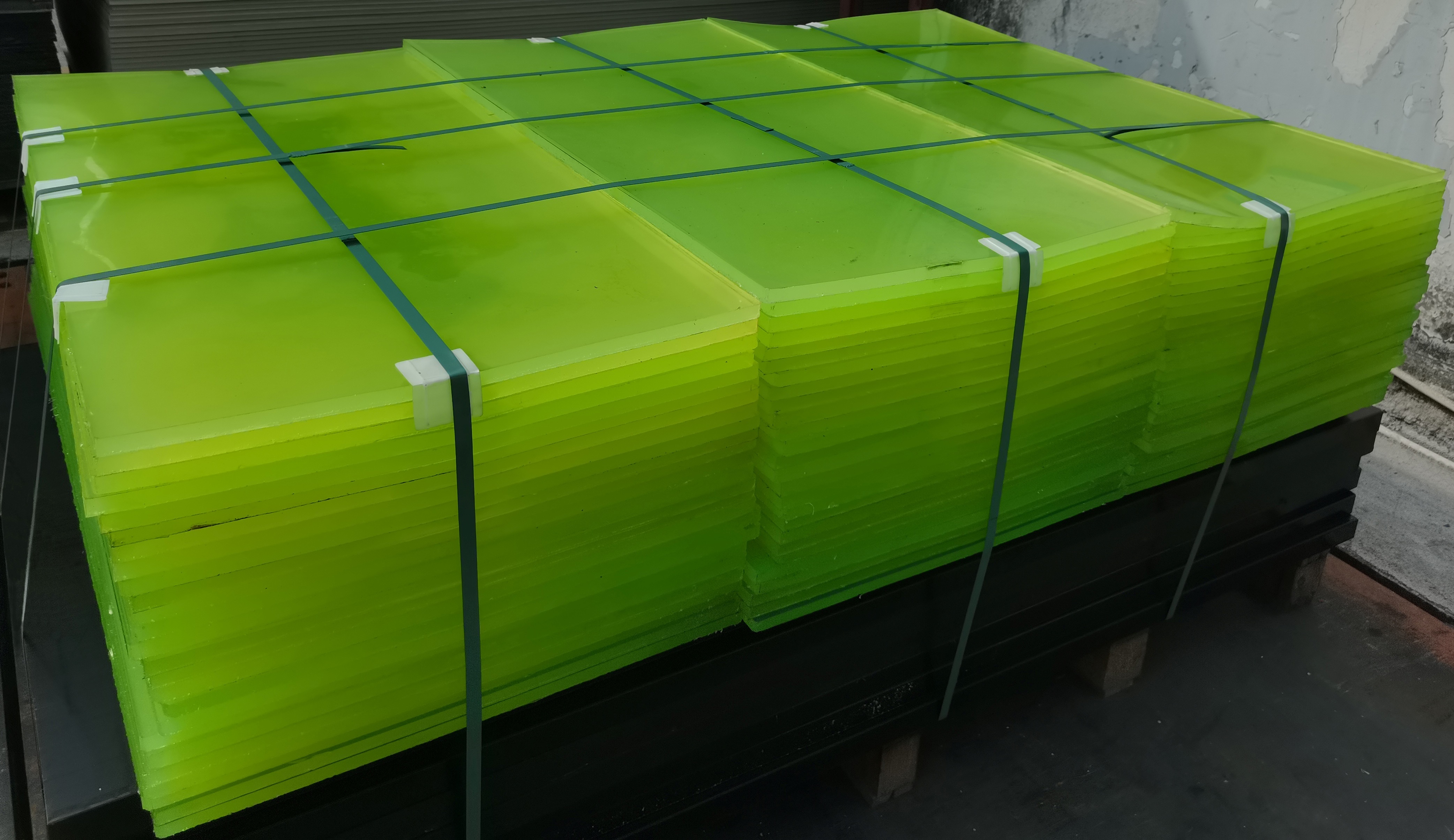

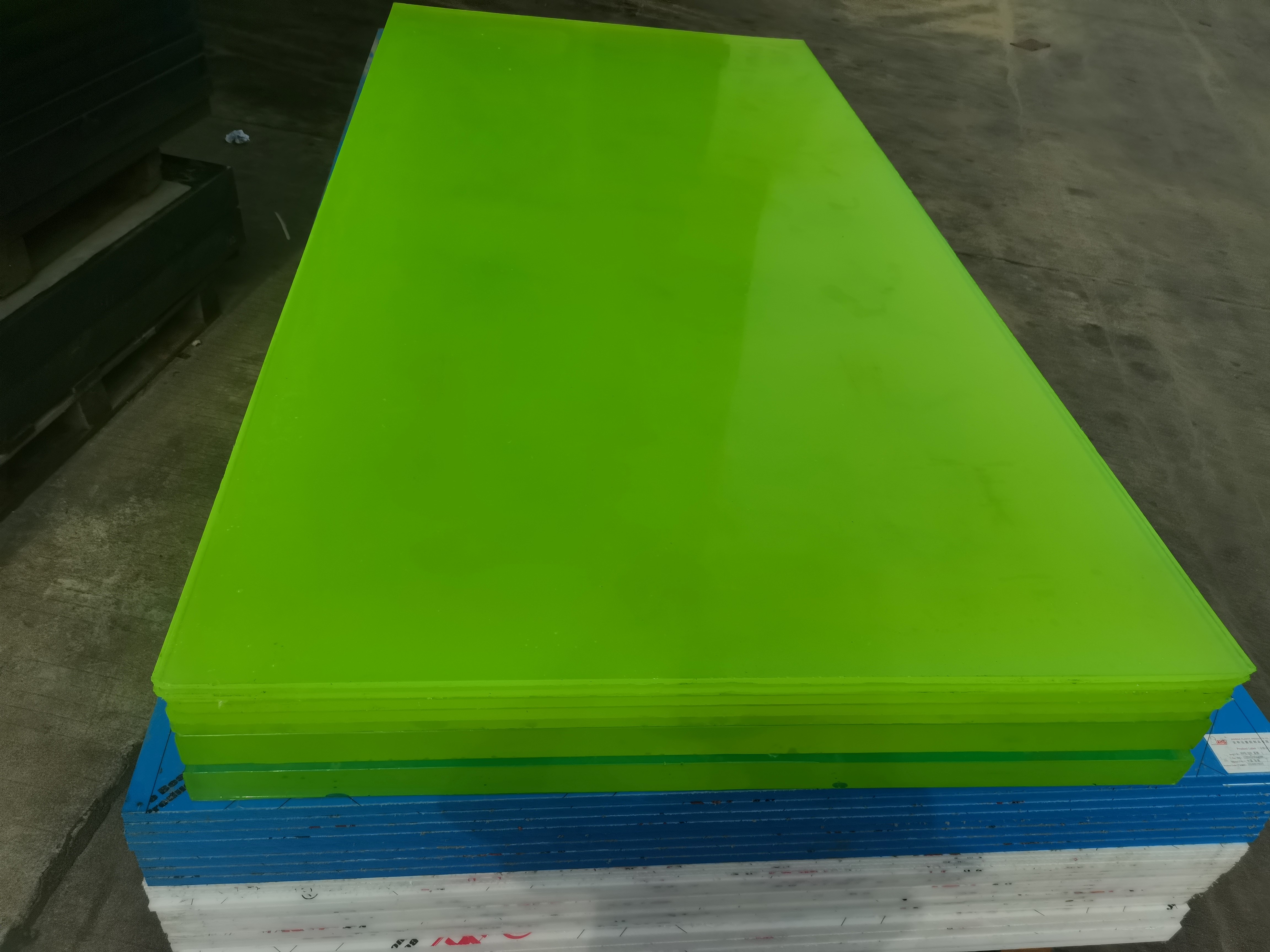

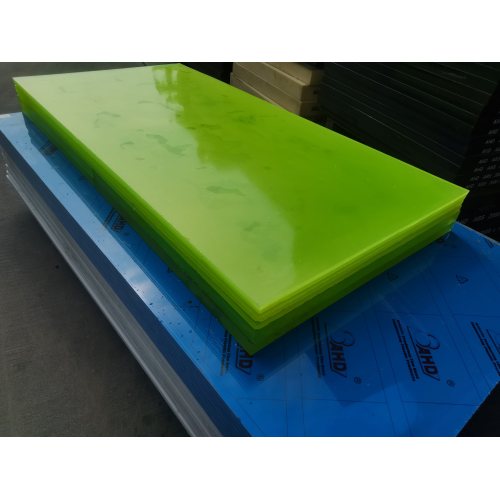

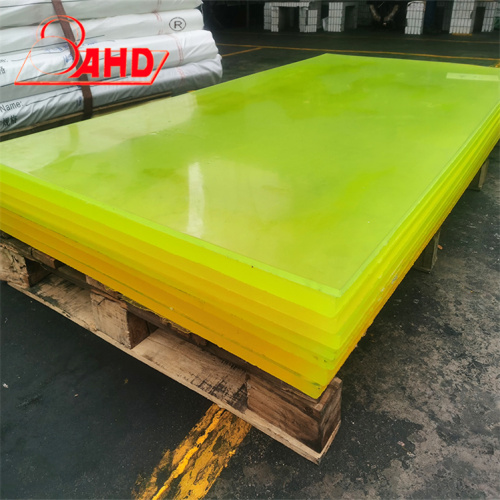

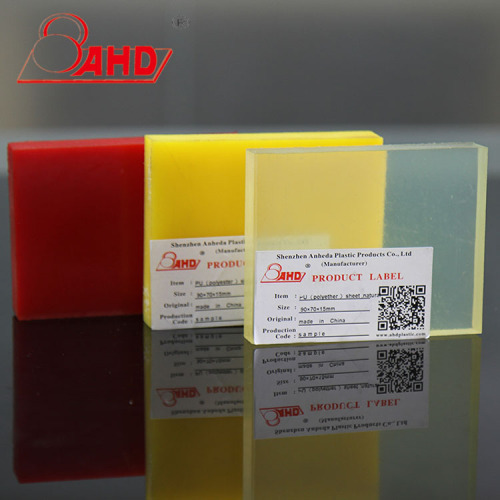

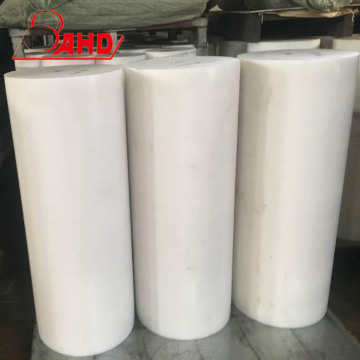

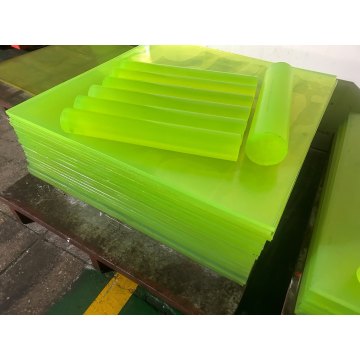

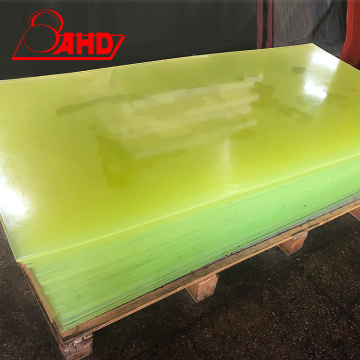

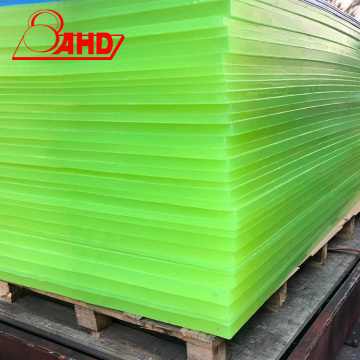

ESD Polyurethane Sheet is a type of board that combines an advanced formula and manufacturing process to integrate the physical characteristics of polyurethane with anti-static functions. It is specifically designed for electrostatic-sensitive environments such as electronics, semiconductors, pharmaceuticals, and precision instrument manufacturing, providing reliable electrostatic protection solutions to prevent electrostatic damage to sensitive components, equipment, and products, ensuring the safety of the production process and the stability of product quality.

- Excellent Anti-static Property: The surface resistance is stably within a specific anti-static range (for example, 10^6 - 10^9 Ω/sq), which can quickly dissipate electrostatic charges and avoid electrostatic discharge, ensuring the safety of operations in electrostatic-sensitive areas and preventing electrostatic interference and damage to electronic equipment and precision instruments, such as chip breakdown and data loss.

- Good Mechanical Properties: It has relatively high tensile strength, tear strength, and elastic modulus, and is not easily deformed or damaged under mechanical stress, meeting the requirements of various complex working conditions. For example, it can be used as a support material for conveyor parts in an automated production line or a protective material for the operating table surface during the assembly of electronic equipment, ensuring long-term and stable performance.

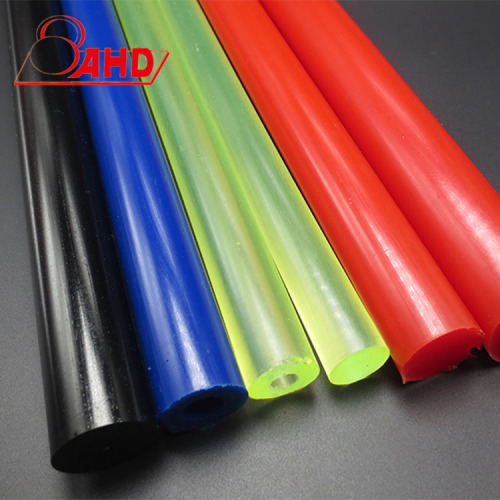

- Excellent Flexibility and Resilience: The material is soft and elastic, easy to be processed into various shapes, and can closely fit curved and irregular surfaces. It can quickly recover its original shape after being subjected to external force, effectively cushioning and protecting the contacted objects and reducing the risk of electrostatic generation due to friction. It plays an important role in the packaging and transportation of electronic components.

- Chemical Resistance: It has a certain tolerance to common chemical substances used in electronic manufacturing, such as solvents, cleaning agents, and acid-base etching solutions, maintaining stable performance in a complex chemical environment, avoiding a decrease in anti-static performance or damage to the material itself due to chemical erosion, prolonging the service life, and reducing maintenance costs.

- Good Abrasion Resistance: The surface is smooth and wear-resistant, maintaining a low surface roughness and stable anti-static performance during long-term friction, reducing the dust generated by wear, preventing the dust from adsorbing static electricity and further affecting the electrostatic-sensitive environment. It is suitable for application scenarios with frequent contact and movement, such as turnover pallets and conveyor belts in an electronic workshop.

- Certain Temperature Resistance: It can maintain relatively stable physical and anti-static properties within a wide temperature range (for example, -40°C to +100°C), adapting to temperature changes in different environments and ensuring that the quality of electronic components and other products is not affected by temperature fluctuations.

- Electronics and Semiconductor Industry

- Used as a covering material for the workbench surface in a chip manufacturing workshop to prevent chips from being damaged by static electricity during processing, testing, and transportation, ensuring a high yield rate and stable performance.

- As a packaging material for electronic components and circuit boards, avoiding electrostatic hazards, reducing the probability of component damage and circuit failure, and saving costs.

- Used for the protection and buffering of key parts inside semiconductor production equipment to ensure that the manufacturing process is not affected by static electricity and to ensure the consistency of product quality.

- Pharmaceutical and Medical Industry

- Used for the ground, shelf lining, and operating table surface protection in a drug production workshop to prevent static electricity from adsorbing impurities into drugs and avoiding damage to the electronic components of medical equipment, ensuring the quality of drugs and the reliability of medical equipment.

- As a ground material or equipment support pad in hospital operating rooms and precision medical instrument rooms, eliminating static electricity and reducing the risk of interference to surgical and monitoring instruments, ensuring the safety and accuracy of the medical process.

- Precision Instrument Manufacturing Industry

- Applied in the processing, assembly, and testing links of parts and components during the manufacturing of optical, precision measurement, and other instruments to prevent static electricity from damaging the precise structure and electronic control system, ensuring the high precision and high sensitivity of the instruments and enhancing the quality competitiveness of the products.

- Used to make the inner lining of packaging boxes and protective pads for the transportation and storage of instruments, providing all-round protection, avoiding static electricity damage caused by vibration and friction during transportation, and ensuring the intact performance of the instruments.

- Other Electrostatic-Sensitive Areas

- Used for equipment protection and static elimination in aerospace electronic equipment cabins, satellite assembly workshops, and other places to ensure the stable operation of aerospace electronic equipment and avoid the impact of electrostatic faults on aerospace missions.

- Used as the inner lining of display cabinets and the surface covering of storage racks in museums and archives to prevent static electricity from adsorbing dust and harmful substances and causing damage to cultural relics and archives, prolonging the preservation life and maintaining the integrity of cultural heritage.