Thickness 20mm 25mm 35mm POM Delrin Sheet

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000 Ton/month |

| Supply Ability: | 3000 Ton/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | SGS/TUV/ISO:2015 |

| Transportation: | Ocean,Air |

| Port: | Shenzhen |

Thickness 20mm 25mm 35mm POM Delrin Sheet

Anheda Plastics has been producing POM sheets since 2008, and POM sheets can easily burst during processing. The POM plates produced by Anheda use heat treatment technology to eliminate this problem. POM board is a hard and dense material with a smooth, shiny surface, light yellow or white, and can be used for a long time in the temperature range of -40-100°C. Its wear resistance and self-lubrication are also superior to most engineering plastics, and it has good oil resistance and peroxide resistance. Very intolerant to acids, strong alkalis and ultraviolet radiation.

Extruded Pom Sheet Main Properties:

Delrin Sheet has good hardness and rigidity, high resistance to creep and stress relaxation, good wear resistance, self-lubricating, and fatigue, which cannot be compared with other engineering plastics.

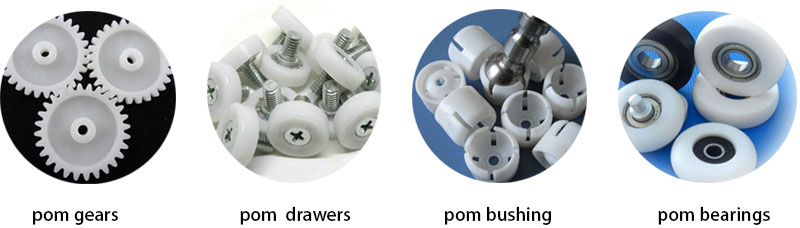

Application:

Delrin Pom Sheet is widely used in the manufacture of various sliding rotating machines, precision parts, gears, bearings and the like. The use of the industry is in the fields of automobiles, electronics, clothing, medical, machinery, sports equipment and so on.

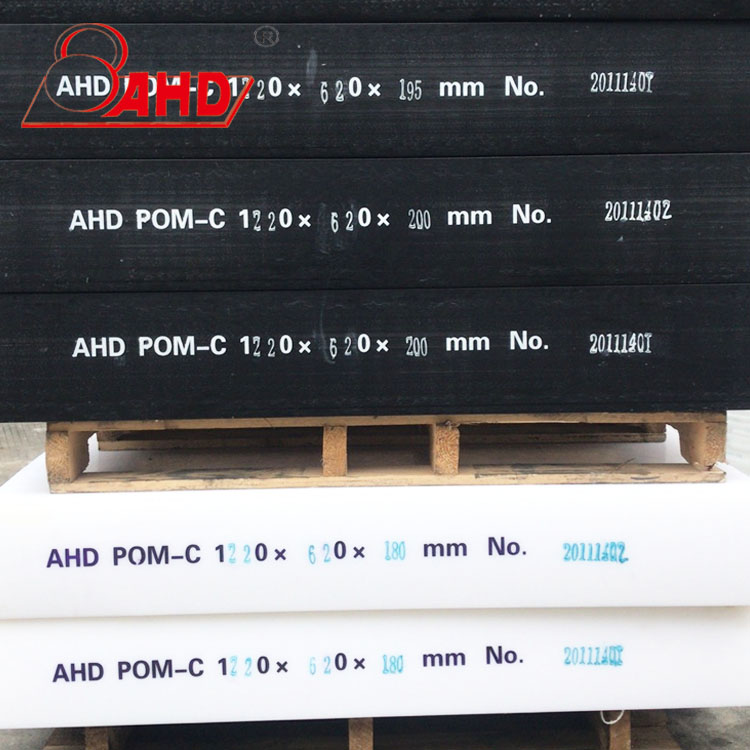

Pom Material Sheet Specification:

|

Item name |

POM-C Sheet |

|

Type: |

extruded |

|

Thickness: |

0.5-150mm |

|

Size: |

1000*2000 / 610*1220mm |

|

Density: |

1.41 g/cm³ |

|

Color: |

White, black |

|

Brand name: |

AHD |

|

Material: |

100% virgin material |

|

Sample: |

FREE |

|

Acid resistance: |

YES |

|

Food Contact |

YES |

Physical Datasheet:

|

Item |

POM (C) Sheet |

|

Color: |

White, Black |

|

Proportion: |

1.41g/cm³ |

|

Heat resistance (continuous): |

115℃ |

|

Heat resistance (short-term): |

140℃ |

|

Melting point: |

165℃ |

|

Linear thermal expansion coefficient (average 23~100℃): |

110×10-6 m/(m.k) |

|

Average 23--150℃ |

125×10-6 m/(m.k) |

|

Flammability(UI94): |

HB |

|

Tensile modulus of elasticity: |

3100MPa |

|

Dipping into water at 23℃ for 24h |

20% |

|

Dipping into water at 23℃ |

0.85% |

|

Bending tensile stress/ Tensile stress off shock |

68/- Mpa |

|

Breaking tensile strain |

˃35% |

|

Compressive stress of normal strain-1%/2%: |

19/35 MPa |

|

Pendulum gap impact test |

7 KJ/m2 |

|

Friction coefficient: |

0.32 |

|

Rockwell hardness: |

M84 |

|

Dielectric strength: |

20 kv/mm |

|

Volume resistance: |

10 14Ω×cm |

|

Surface resistance: |

10 13Ω |

|

Relative dielectric constant-100HZ/1MHz: |

3.8/3.8 |

|

Critical tracking index(CTI) |

600 |

|

Bonding capacity: |

+ |

|

Food contact: |

+ |

|

Acid resistance: |

+ |

|

Alkali resistance |

+ |

|

Carbonated water resistance: |

+ |

|

Aromatic compound resistance: |

+ |

|

Ketone resistance: |

+ |

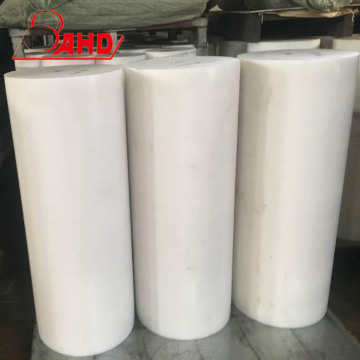

POM SHEET Goods Photos:

Packing:

Iron pallets on bottom, wrapped with tarpaulin, the surface is covered with PE film.

Exhibition:

Anheda group is invited to participate in domestic and international trade exhibitions every year as the most representative exhibitor,has widely attracted the attention of customers from all over the world.It making anheda group play more loudly, spread farther and have wider influence.

About us:

Anheda Plastics Group is located in the Shenzhen Special Economic Zone, adjacent to Hong Kong, with convenient transportation by sea, land and air.

Since its establishment, the company has put quality first, and adheres to the tenet of [Science and Technology, Cultivation of More Talents, Technology Development and Growth, and Innovation of Technical Talents". Our company is growing and developing step by step, and its economic strength is constantly improving, and its competitive advantage continues to stand out. We always abide by the business philosophy of "Quality First, Customer First", and customer satisfaction is our driving force.

Acetal Sheet FAQ:

Q1:How do you ship samples?

A1:Considering sample quantity is not big, we support ship samples by DHL,TNT or fedex , fast and less damages.

Q2:How do I know your quality?

A2: Free sample will be able to verify our quality.

Q3: What`s payment?

A3: T/T,L/C,Western Union etc. About the payment details please feel free to contact free to contact us.Thank you!

Q4:How to control quality?

A4:When we confirm one color and our customer's specific requirements, we will control strictly, our QA engineer will use our device to test the sheet performance, dimension, color etc.

Q5:How many days will the samples be finished?And how about the mass production?

A5: Generally the samples will be sent immediately by the air express in 1--3 days, the leading time mass production is depended on the stock status and sizes.

Related Keywords