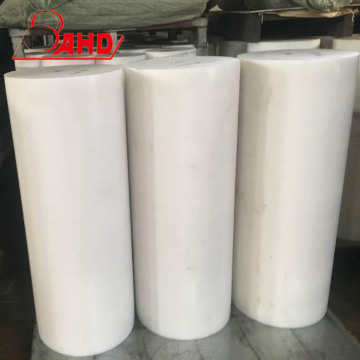

White Rod POM Plastic POM-C Nat Rod

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000 Ton/month |

| Supply Ability: | 3000 Ton/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | SGS/TUV/ISO:2015 |

| Transportation: | Ocean,Air |

| Port: | Shenzhen |

POM rod , English name polyoxymethylene, commonly known as steel rod, steel rod, super steel rod is extruded with POM plastic particles through the extruder at high temperature, through the corresponding die extrusion to obtain different thickness Bar. It is a high hardness, high crystalline thermoplastic engineering plastic.

Main Properties:

POM-C / H (black, white), representing POM copolymer and polyoxymethylene homopolymer, respectively, polyoxymethylene copolymer with low melting point, thermal stability, chemical resistance, flow characteristics, hydrolysis resistance, alkali resistance and heat resistance Oxidation degradation, processability is better than homopolyformaldehyde. POM homopolymer has high crystallinity, creep resistance, lower thermal expansion rate, wear resistance, mechanical strength, rigidity, heat distortion temperature and so on. (POM-C copolymer is commonly used in POM semi-finished products on the market)

Application:

Due to the good characteristics of POM rods, it is very suitable for machining on automatic lathes, especially for the manufacture of precision parts.

Extruded Pom Rod Specification:

|

Item name |

POM-C Rod |

|

Type: |

extruded |

|

Diameter: |

Ø15---300mm |

|

Length: |

1000mm |

|

Density: |

1.41g/cm³ |

|

Color: |

White, Black |

|

Brand name: |

AHD |

|

Material: |

100% virgin material |

|

Sample: |

FREE |

|

Acid resistance: |

YES |

|

Food Contact |

YES |

Physical Datasheet:

|

Item |

POM (C) |

|

Color: |

White,Black |

|

Proportion: |

1.41g/cm³ |

|

Heat resistance (continuous): |

115℃ |

|

Heat resistance (short-term): |

140℃ |

|

Melting point: |

165℃ |

|

Linear thermal expansion coefficient (average 23~100℃): |

110×10-6 m/(m.k) |

|

Average 23--150℃ |

125×10-6 m/(m.k) |

|

Flammability(UI94): |

HB |

|

Tensile modulus of elasticity: |

3100MPa |

|

Dipping into water at 23℃ for 24h |

20% |

|

Dipping into water at 23℃ |

0.85% |

|

Bending tensile stress/ Tensile stress off shock |

68/- Mpa |

|

Breaking tensile strain |

˃35% |

|

Compressive stress of normal strain-1%/2%: |

19/35 MPa |

|

Pendulum gap impact test |

7 KJ/m2 |

|

Friction coefficient: |

0.32 |

|

Rockwell hardness: |

M84 |

|

Dielectric strength: |

20 kv/mm |

|

Volume resistance: |

10 14Ω×cm |

|

Surface resistance: |

10 13Ω |

|

Relative dielectric constant-100HZ/1MHz: |

3.8/3.8 |

|

Critical tracking index(CTI) |

600 |

|

Bonding capacity: |

+ |

|

Food contact: |

+ |

|

Acid resistance: |

+ |

|

Alkali resistance |

+ |

|

Carbonated water resistance: |

+ |

|

Aromatic compound resistance: |

+ |

|

Ketone resistance: |

+ |

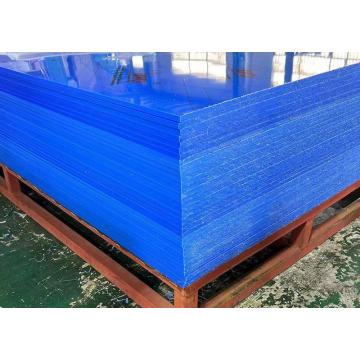

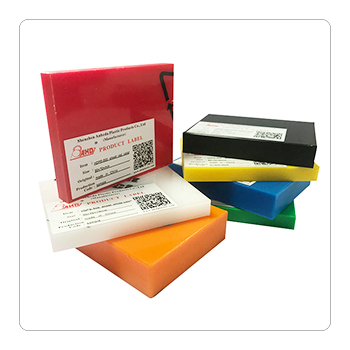

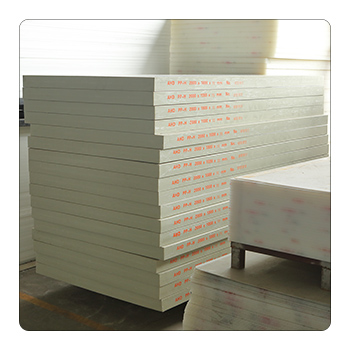

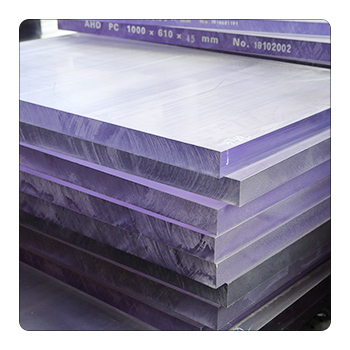

Polyformaldehyde Rod Goods Photos:

Other Products:

|

|

|

|

Hdpe Plastic Sheets |

PA6 Sheet |

POM Rod |

|

|

|

|

Polypropylene Sheet |

POM Sheet |

PC Sheet |

Certificate:

Customers Visit:

About us:

Anheda group is invited to participate in domestic and international trade exhibitions every year as the most representative exhibitor,has widely attracted the attention of customers from all over the world.It making anheda group play more loudly, spread farther and have wider influence.

As the most representative exhibitor, the Anheda Group is invited to participate in national and international exhibitions every year. At the same time, it has attracted extensive attention from customers all over the world, making the anheda group more famous, spreading farther and more influential.

FAQ:

Q1:What's your delivery time?

A1:For samples: within 1-3 working days; For orders: within 7-30 working days.

Q2:What is the minimum ordering quantity ?

A2:MOQ can be a small quantity even 100 kgs to meet various needing .

Q3:What's the cost of the sample?

A3:The sample cost is free, but if you can afford the freight we will appreciate.

Q4:How to control quality?

A4:When we confirm one color and our customer's specific requirements, we will control strictly, our QA engineer will use our device to test the sheet performance, dimension, color etc.

Q5:How about your package?

A5:Firstly we will use PE film pack the sheets inside, secondly the outside we will use kraft paper film to pack, then use wrapping film to enlace, the top we will cover cardboard. Usually we use pallets to pack, if you want to pack in bulk, we also can satisfy your needs.

Related Keywords