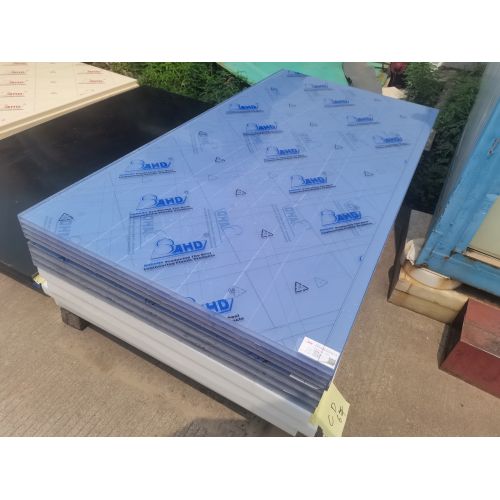

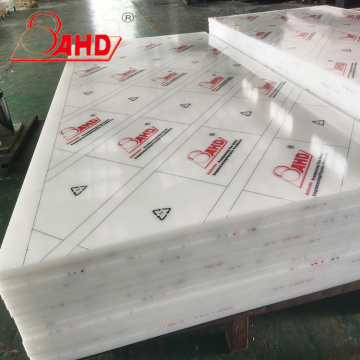

PC Sheet is made from polycarbonate resin through processes such as extrusion, injection molding, or calendering. Thanks to the unique molecular structure of polycarbonate, the sheet has a series of outstanding properties including high strength, high transparency, high toughness, heat resistance, weather resistance, and dimensional stability. It is widely used in many fields such as construction and the automotive industry, and has become a crucial material in modern industrial production and daily life, providing a strong impetus for the innovation and function improvement of various products.

- Outstanding Mechanical Properties

- High Strength and Toughness, as Solid as a Rock: It has excellent tensile and bending strength and can easily withstand large external impacts. Its toughness is even more remarkable. When subjected to impact, it can quickly absorb energy and disperse stress, effectively preventing breakage. It is often used in key protective parts such as the inner layer of bulletproof glass and protective barriers to safeguard lives and property.

- Accurate Dimensions, as Stable as Mount Tai: Even when facing significant fluctuations in temperature and humidity, it can still maintain accurate dimensional accuracy. The coefficient of thermal expansion is extremely low, which is of great significance for precision instruments and electronic products, greatly reducing the risk of malfunctions caused by dimensional changes and ensuring the long-term stable operation of the equipment.

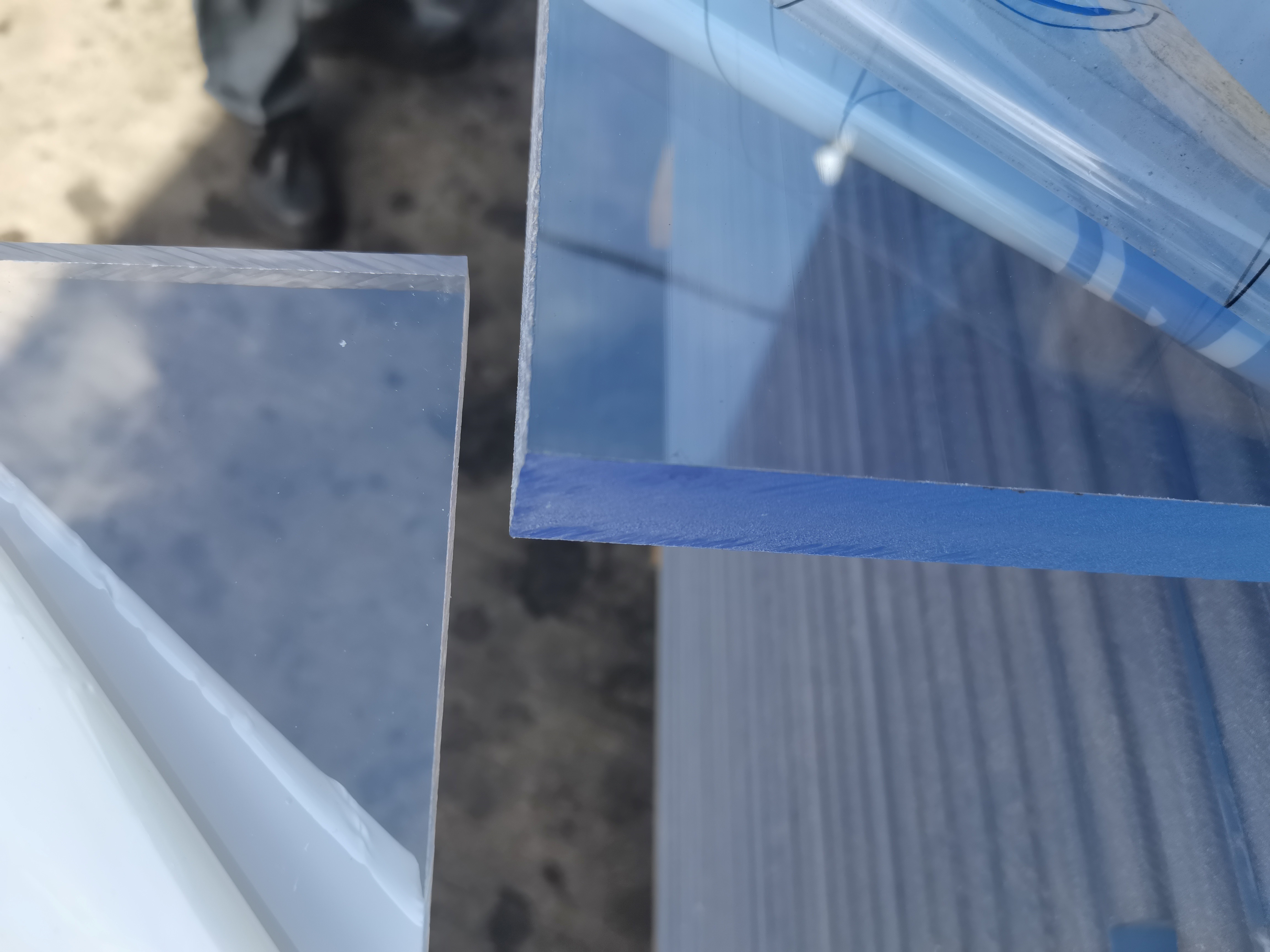

- Brilliant Optical Properties

- High Transparency, as Clear as Water: The light transmittance reaches 85% - 92%, almost as clear as glass, and there is minimal distortion when light passes through. It is used in skylights, curtain walls, lamp shades, and other scenarios, allowing sufficient natural light to pour in and creating a magnificent visual effect.

- Optical Stability, Everlasting: Under long-term exposure to light, its optical properties remain as stable as a rock. There will be no yellowing, fogging, or reduction in light transmittance, greatly extending the service life of outdoor lighting fixtures and light boxes and reducing the cost of frequent replacements.

- Excellent Chemical Resistance Properties

- Resistant to Multiple Erosions, Invulnerable to All Kinds of Chemicals: It has good tolerance to common acid-base solutions and organic solvents, and can strongly resist corrosion under specific conditions, ensuring that the material's performance and appearance remain intact. It is often used in chemical laboratory countertops, reagent containers, and other places with harsh chemical environments.

- Strong Water Resistance, Impervious to Water: The water absorption is almost zero. Even if it is soaked in water for a long time, it will never absorb water, completely eliminating the problem of material deterioration caused by water absorption. It can be reliably used in waterfront buildings, aquariums, and various humid environments.

- Outstanding Weather Resistance Properties

- Withstanding Harsh Climates, Fearless of Wind and Rain: It has excellent weather resistance and can maintain a stable state for a long time whether in high temperatures, severe cold, or under strong ultraviolet radiation. It is widely used in outdoor buildings, traffic signs, and other fields, reducing maintenance costs with its super durability.

- Superior Anti-aging Properties, Always Youthful: During long-term outdoor use, it is not prone to aging and degradation. The molecular structure remains stable, effectively delaying the appearance of aging symptoms such as surface cracking, embrittlement, and fading, and always maintaining good performance.

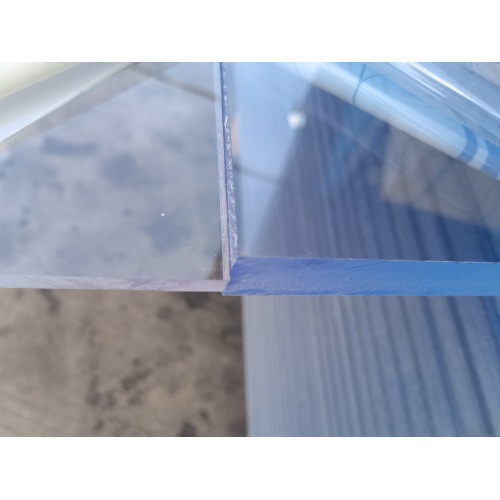

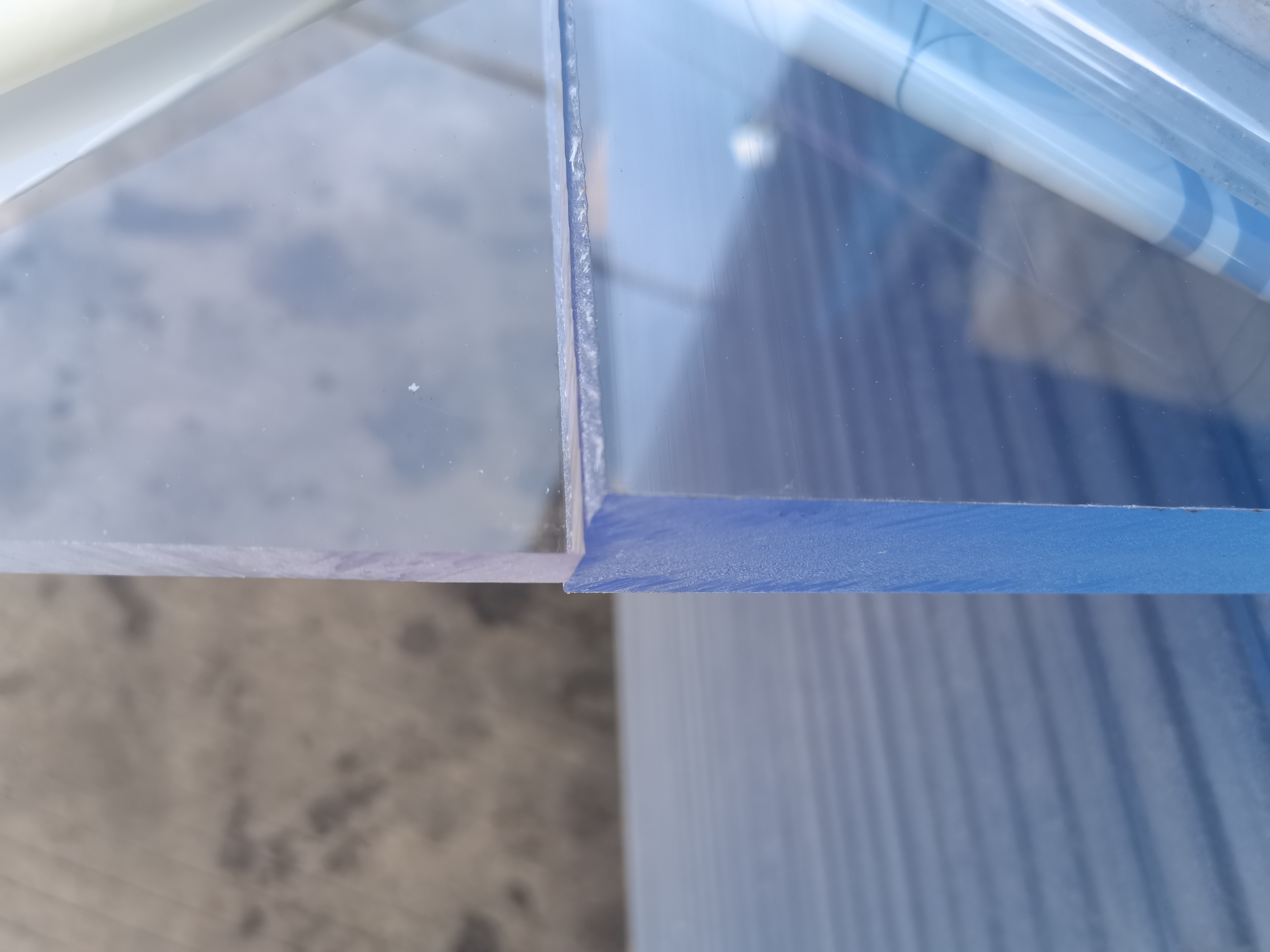

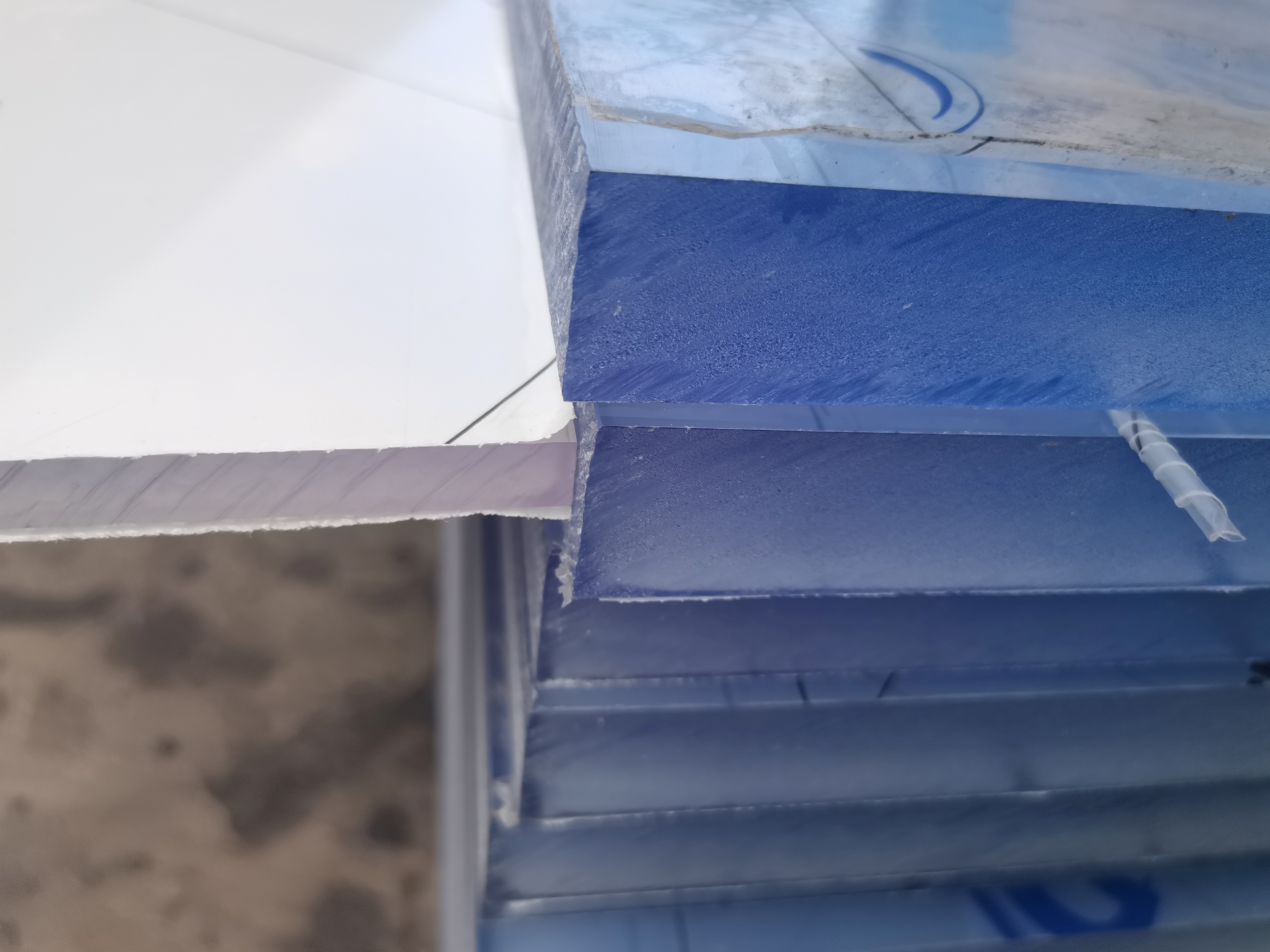

- Excellent Machining Properties

- Easy to Cut and Form, with Great Ease: With the help of conventional plastic processing equipment, operations such as cutting and punching can be easily achieved. The cutting edges are smooth and flat, and the punching accuracy is extremely high. Thermoforming can create complex three-dimensional shapes, perfectly meeting various customization requirements, greatly shortening the product development cycle and improving production efficiency.

- Partially Injection Moldable, Highly Efficient and Precise: Specific specifications of PC Sheet can be injection molded. The produced parts have excellent consistency, super high precision, and extremely high production efficiency. They are especially suitable for mass-producing small and precise PC parts, such as micro lenses in electronic appliances, providing strong support for the miniaturization and precision production of modern industry.

- Construction Industry

- Daylighting and Curtain Walls: Used in skylights and curtain walls, it features high transparency, weather resistance, and high strength, providing ample daylighting, withstanding natural elements, beautifying large buildings, and enhancing environmental protection performance.

- Indoor Decoration and Partitions: Employed to make ceilings, wall decorative panels, etc., with a variety of colors and textures, sound insulation, and heat insulation properties, creating personalized indoor spaces and improving environmental quality.

- Building Protection Facilities: Serves as protective barriers in industrial buildings and sunshades in stadiums, balancing daylighting, shading, and protection to ensure the stable operation of facilities.

- Automotive Industry

- Windshields and Windows: Frequently used for windshields and vehicle windows, it is strong, tough, and has good optical properties, preventing collisions, ensuring clear vision, and enhancing driving safety and comfort.

- Interior Components: Used to manufacture instrument panels, center consoles, etc., with high transparency, easy processability, and aesthetics, enabling refined modeling and excellent functions, improving the quality and technological feel of the interior.

- Lamps and Lamp Shades: Applied to automotive lamps and lamp shades, it has high transparency, stable optical properties, and strong weather resistance, ensuring nighttime illumination and enhancing traffic safety.

- Electronics and Electrical Appliances Industry

- Display Screens and Touch Screens: It is a key material for electronic display screens and touch screens, with high transparency, excellent optical properties, and dimensional stability, driving the development of electronic devices towards being thinner, higher-definition, and smarter.

- Housings and Protective Covers: Used for the housings of electronic devices and protective covers of circuit boards, etc., with high strength, high toughness, and impact resistance, protecting components and extending service life, meeting design requirements.

- Optical Instrument Lenses: Utilized in microscopes, cameras, and other optical instruments, it has high transparency, low dispersion, and dimensional stability, helping optical instruments improve resolution and performance.

- Aerospace Field

- Canopies and Windows: Often adopted for aircraft canopies and windows, it is strong, highly transparent, and weather-resistant, capable of withstanding impacts, ensuring clear vision, and contributing to weight reduction, which is of great significance for aviation.

- Interior Components: The interior decorative panels, luggage racks, and the housings of aerospace electronic equipment use PC Sheet. Its comprehensive performance meets the standards, ensuring safety, comfort, and the operation of equipment.

- Satellite and Spacecraft Components: Used for protective covers of solar panels on satellites and spacecraft, etc., it is radiation-resistant, resistant to high and low temperatures, and dimensionally stable, supporting space exploration.

- Advertising and Display Industry

- Advertising Light Boxes and Display Racks: Used as panels for advertising light boxes and display boards for racks, it has high transparency, stable optical properties, and easy processability, making advertising images clear and long-lasting, facilitating brand promotion.

- Signage and Direction Signs: Employed for traffic and scenic area signs, it has high transparency, weather resistance, and impact resistance, ensuring clear readability and guiding travel safety.

- Exhibition Display Props: Used for art, product exhibition props, and display cabinet panels, with a variety of specifications, treatment methods, and good processability, presenting unique visuals and highlighting the charm of exhibits.