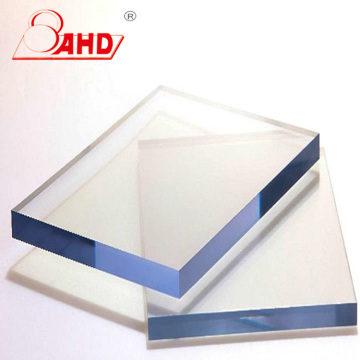

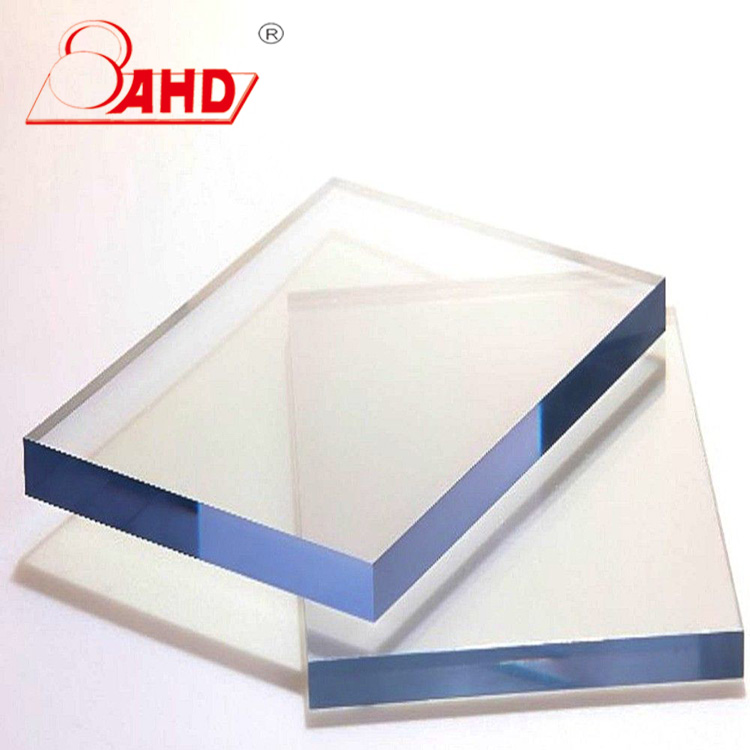

High Quality Extruded Transparent PC Polycarbonate Sheet

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | made in China |

|---|---|

| Productivity: | 3000tons/month |

| Supply Ability: | 3000tons/ month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,DDU |

| Certificate: | SGS, TUV |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

Polycarbonate Sheet is a kind of good comprehensive performance engineering plastics It provides the best mechanical property and electrical insulation, high dimensional stability and excellent creep resistance. Polycarbonate`s toughness and optical clarity make it ideal for a wide variety of applications.

Properties:

- Perfect transparency and the light transmittance with 93%

- Excellent electrical insulation

- Light in weight

- High plasticity

- Processing and shaping easier

- Strong surface hardness and good weather resisting property

- Beautiful in color

Application:

♦ Impact strength parts

♦ Architectural glazing

♦ Skylights, transparent manifolds

♦ Semiconductor machinery components

♦ Optical materials, lighting materials, medical equipment

Specification:

| Item name | PC ( Polycarbonate) sheet |

| Type: | extruded |

| Thickness: | 3--200mm |

| Size: | 610x1220mm,1000x2000mm, 1220x2440mm |

| Density: | 1.2 g/cm³ |

| Color: | Translucent, black |

| Brand name: | AHD |

| Material: | 100% virgin material |

| Sample: | FREE |

| Acid resistance: | YES |

| Food Contact | YES |

Physical Datasheet:

| Item | PC ( Polycarbonate) sheet |

| Type | extruded |

| Size | 610x1220mm,1000x2000mm, 1220x2440mm |

| Thickness | 1--200mm |

| Color | Transparency |

| Proportion | 1.2g/cm³ |

| Heat resistance (continuous) | 125℃ |

| Heat resistance (short-term) | 135℃ |

| Melting point | _ |

| Glass transition temperature | 150℃ |

|

Linear thermal expansion coefficient

(average 23~100℃)

|

65×10-6m/(m.k) |

| Average 23--150℃ | 65×10-6m/(m.k) |

| Flammability(UI94) | HB |

| Tensile modulus of elasticity | 2400MPa |

| Dipping into water at 23℃ for 24h | 0.13 |

| Dipping into water at 23℃ | 0.35 |

| Bending tensile stress/ Tensile stress off shock | 70/- Mpa |

| Breaking tensile strain | >50% |

| Compressive stress of normal strain-1%/2% | 18/35 MPa |

| Pendulum gap impact test | 9 KJ/m2 |

| Friction coefficient | 0.55 |

| Rockwell hardness | M75 |

| Dielectric strength | 28 kv/mm |

| Volume resistance | ≥10 15Ω×cm |

| Surface resistance | ≥10 15Ω |

| Relative dielectric constant-100HZ/1MHz | 3/3 |

| Critical tracking index(CTI) | 600 |

| Bonding capacity | + |

| Food contact | + |

| Acid resistance | + |

| Alkali resistance | - |

| Carbonated water resistance | 0 |

| Aromatic compound resistance | - |

| Ketone resistance | - |

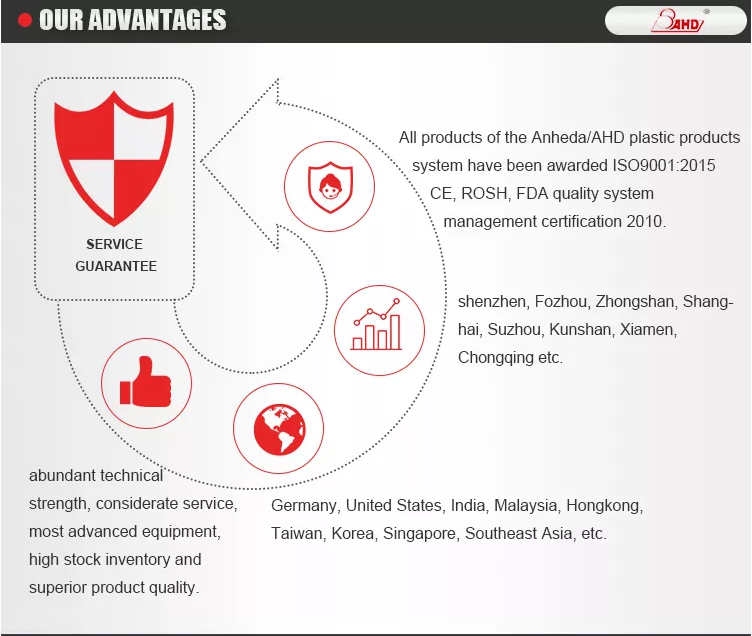

About us:

Founded in 1994, Anheda Group is a group company that develops, manufactures and sells semi-finished engineering plastics in China. The main products are POM, PC, ABS, PP, PE, PA6, PU, PEI sheet and bar. It is one of the The first companies in China to obtain independent import and export rights. By 2017, eight branches have been established throughout the country. Products are exported to six continents, Europe, North America, South America, Africa, Oceania and Asia. Group can meet the requirements Of customers and find the best solution for each customer. In addition, we can help our customers stay competitive and benefit every customer from the best products.

FAQ:

Q1: Are you a factory or trade company?

A1: we are a manufacturter for semi-finished engineering plastic sheet & rod like "

Polypropylene Plastic Sheet,Nylon Sheet,Pa6 Rod,Abs Plastic Sheet,Abs Plastic Sheet ,PP Rod and Sheet, POM Sheet, PC Sheet"etc since 1994.

Q2: Is your sample free?

A2:Yes, our samples are free, but the shipping cost is paid by the buyer.

Q3: What about the MOQ ?

A3:In addition to the sample, the minimum order quantity for a regular size product is 100kgs.

Q4: What about the packing ?

A4: As per factory's exported standard, usually use steel pallets.

Q5: What about the payment term ?

A5:we accept payment by L/C , T/T, usually 30% deposit is requested before production. 50% deposit is request for customzied items.

Q6: What's your delivery time?

A6:For samples: within 1-3 working days; For orders: within 7-30 working days.

Related Keywords