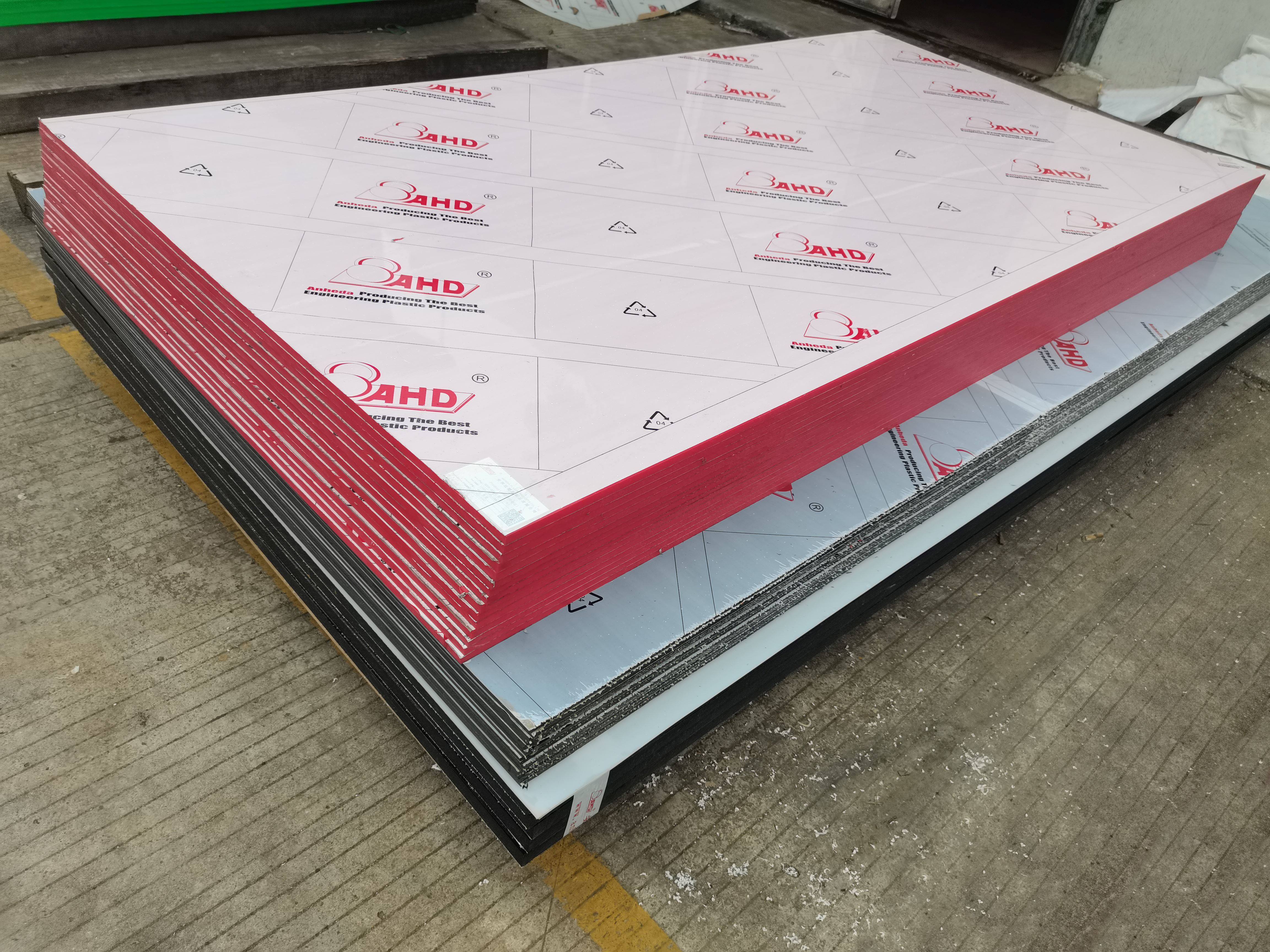

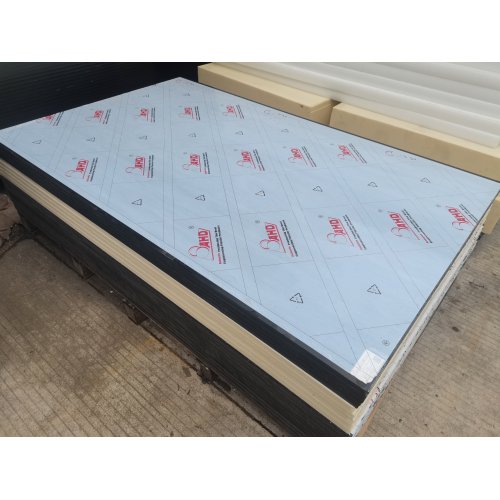

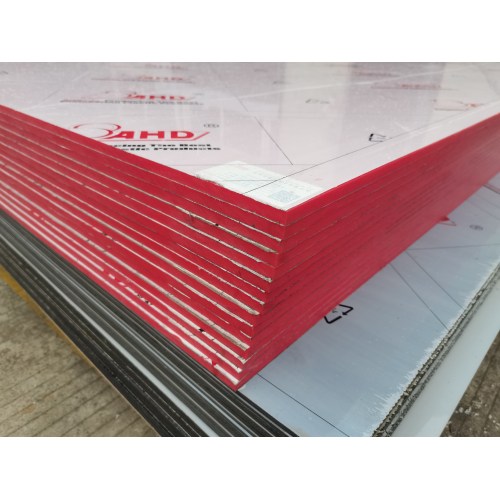

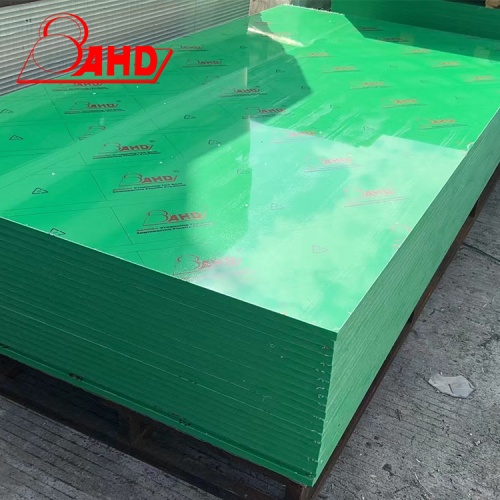

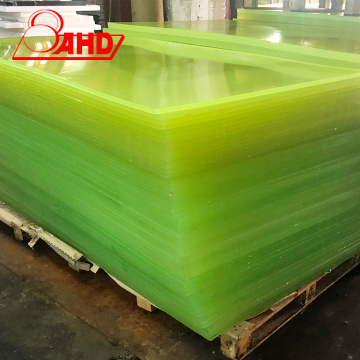

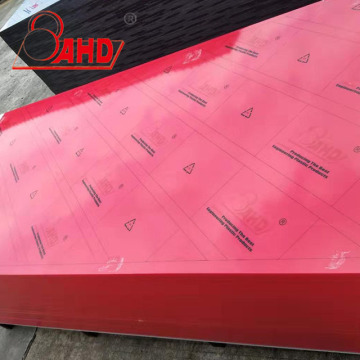

HDPE Sheet refers to high-density polyethylene sheet, which is a kind of plastic sheet made from high-density polyethylene resin through extrusion or calendering processes.

- High Strength and Toughness: It has excellent tensile strength and impact toughness, capable of withstanding relatively large external forces without being easily broken or damaged, and can be used in harsher environments and working conditions.

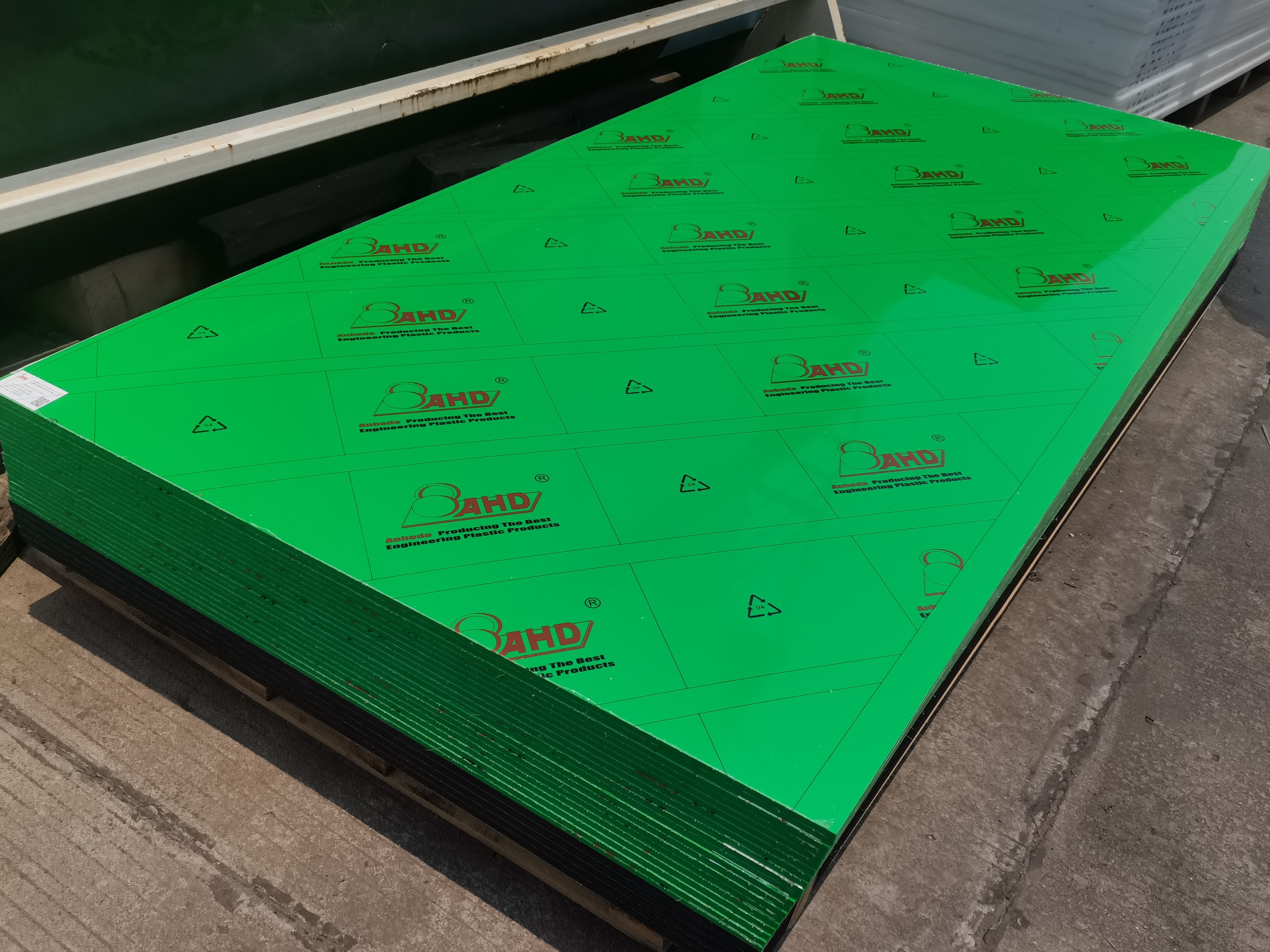

- Chemical Resistance: It shows remarkable tolerance to a variety of chemical substances, including acid, alkali, salt solutions, and some organic solvents. When applied in the chemical and environmental protection fields, it can effectively resist the erosion of chemical media and maintain the stability of its own structure and performance.

- Low Water Absorption: It has extremely low water absorption. When in a humid environment or in contact with water, it will not experience performance degradation such as dimensional changes or strength reduction due to excessive water absorption, thus ensuring its long-term reliability in use.

- Good Abrasion Resistance: The surface is smooth and wear-resistant. In scenarios such as material conveying and machinery manufacturing, it can effectively reduce the wear caused by friction with other objects, extend the service life, and reduce maintenance costs.

- Low-Temperature Resistance: Even in low-temperature environments, it can still maintain good flexibility and mechanical properties, and will not crack like some brittle materials. It can be applied to relevant facilities construction and equipment manufacturing in cold regions or under low-temperature working conditions.

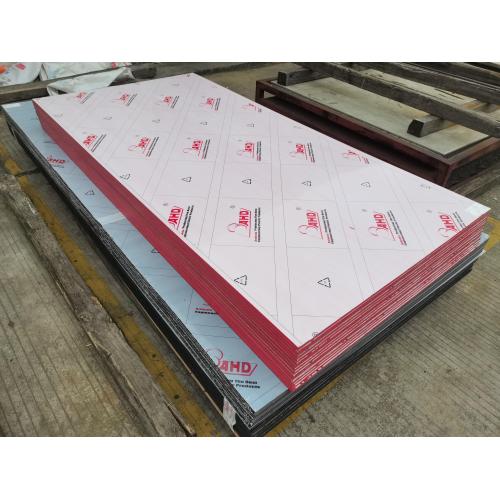

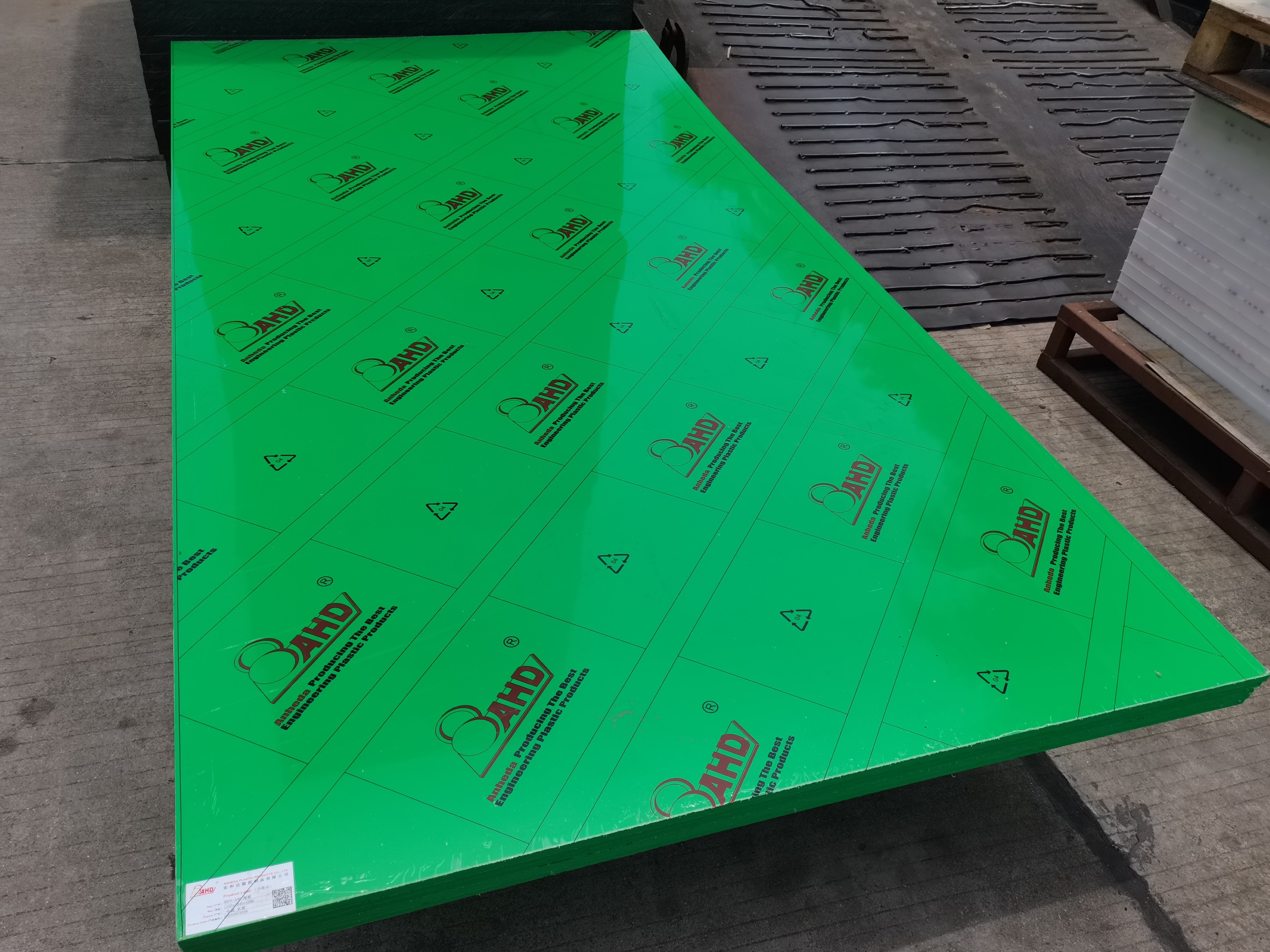

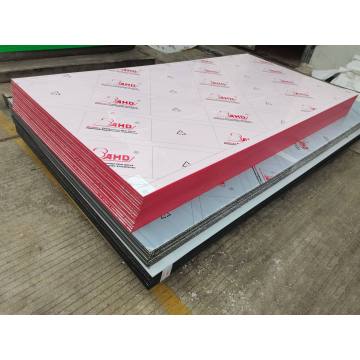

- Construction Industry: It can be used to make waterproof rolls, moisture-proof layers, and building formworks. Its waterproof performance can effectively prevent rainwater penetration and protect the building structure. When used as a formwork, it has the advantages of being lightweight, easy to demould, and reusable, which can reduce the construction cost.

- Chemical Industry: Due to its chemical resistance, it is often used to make linings, storage tanks, and pipes for chemical equipment. It ensures the safe and stable operation of the equipment when handling various corrosive chemicals and prevents chemical leakage from causing harm to the environment and personnel.

- Environmental Protection Field: It is an ideal material for the construction of landfill sites and sewage treatment ponds. It can be used to make anti-seepage membranes and protective linings to prevent sewage and landfill leachate from polluting the soil and groundwater, playing a crucial role in environmental protection.

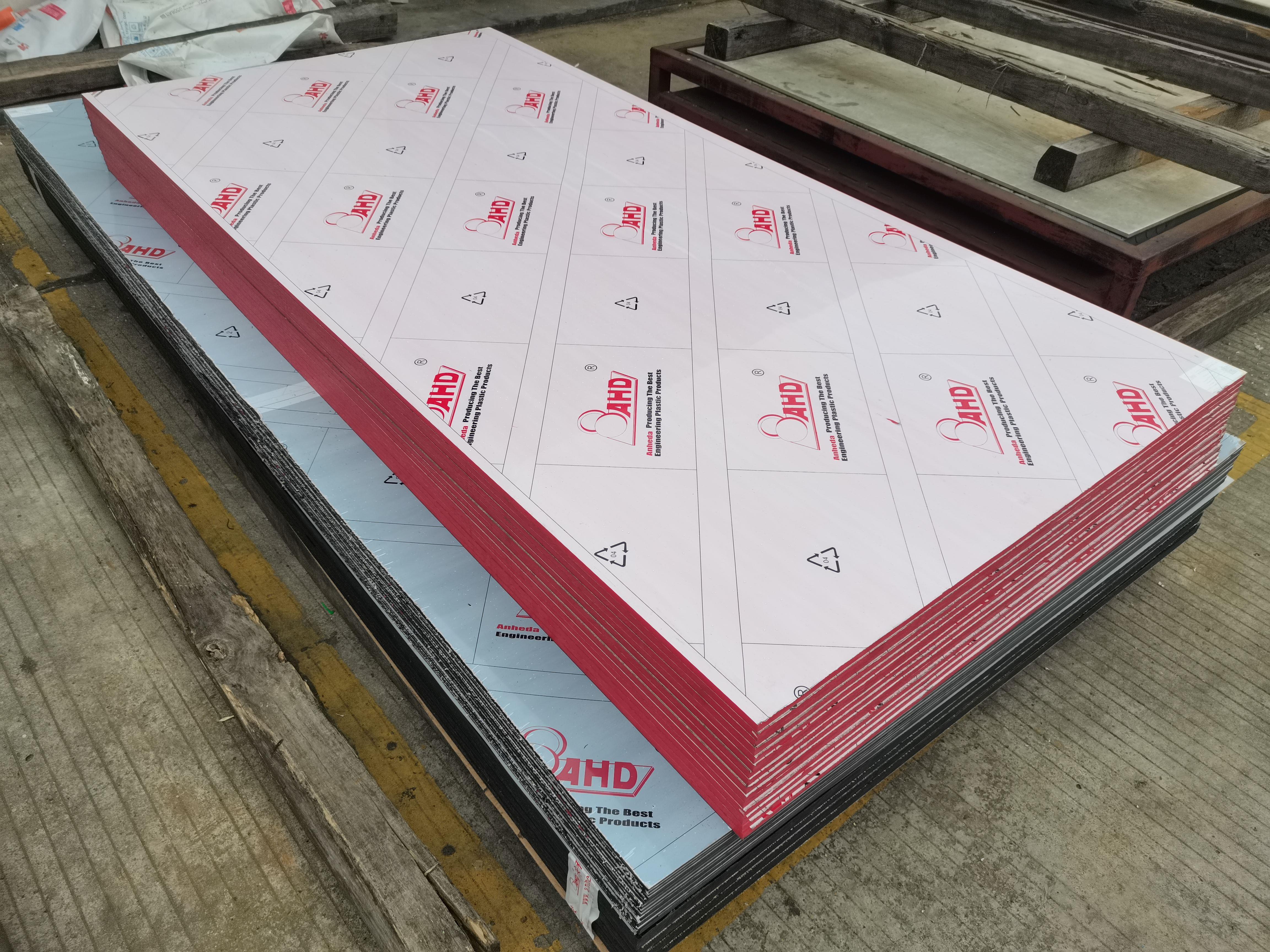

- Industrial Manufacturing: In machinery manufacturing, it can be used as protective plates for components, slides, and conveyor belt pallets. Its abrasion resistance and low friction characteristics can reduce energy consumption and component wear during equipment operation, improving production efficiency and equipment service life.

HDPE Sheet is easy to process and can be made into various shapes and structures of products through multiple processing methods such as cutting, welding, and thermoforming. Cutting can be achieved by mechanical cutting, laser cutting, etc., which can accurately obtain the required size and shape. Welding can be carried out by hot gas welding, extrusion welding, etc., making the sheets firmly connected to meet the production requirements of large structural parts or sealed containers. Thermoforming can heat and soften the sheet and then press it into products with specific curved surfaces or shapes through molds, such as plastic pallets and container lids.

- High Cost-Effectiveness: Compared with some metallic materials or high-performance engineering plastics, HDPE Sheet has a lower cost while being able to provide sufficient performance guarantees in many application scenarios, having a high cost-effectiveness ratio and effectively reducing the production costs of enterprises and project investments.

- Lightweight: It has a relatively low density, and the products made from it are lightweight, which is convenient for transportation, installation, and operation. In some fields with weight requirements, such as aerospace and automotive manufacturing (interior components, etc.), it has certain application potential and can reduce the structural weight without affecting the overall performance.

- Recyclable: It belongs to recyclable plastics. The discarded HDPE Sheet products can be recycled and reprocessed into new plastic products or other products, which conforms to the concept of sustainable development and helps to reduce resource waste and environmental pollution.