SMT printed circuit board pcb assembly electronic pcba

- Payment Type:

- T/T, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 5-30 Days

- Transportation:

- Ocean, Land, Air, UPS

- Port:

- Shenzhen, HongKong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen China |

|---|---|

| Productivity: | 500,000pcs per Month |

| Supply Ability: | 500,000pcs per Month |

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO9001, IATF16949, IPC-A-610F |

| HS Code: | 8517709000 |

| Transportation: | Ocean,Land,Air,UPS |

| Port: | Shenzhen,HongKong |

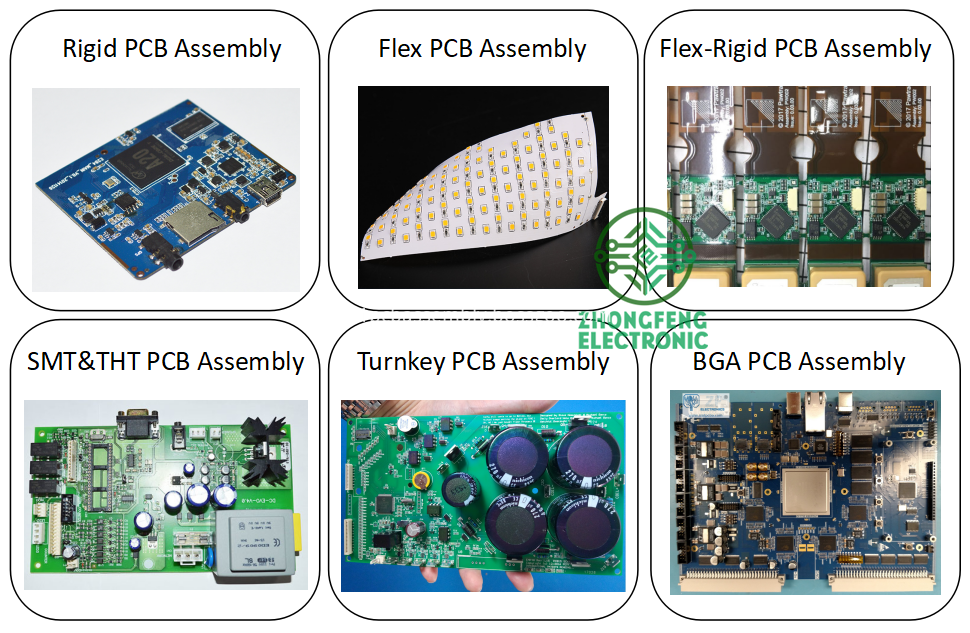

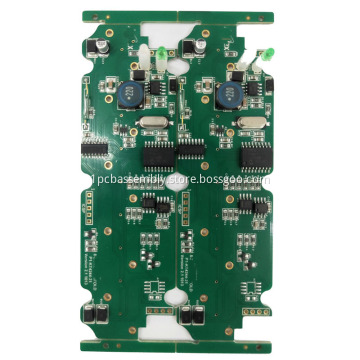

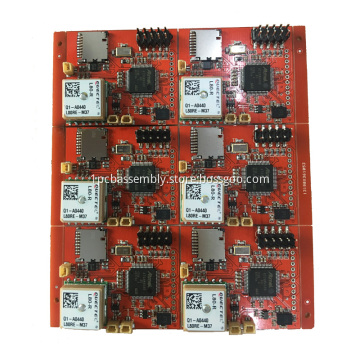

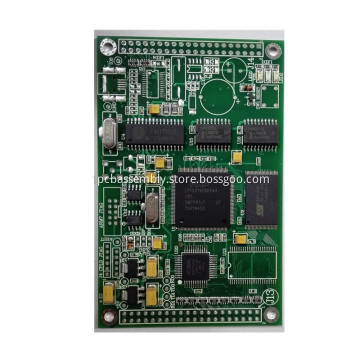

SMT printed circuit board pcb assembly electronic pcba

attachment of electronic components to a PCB, proper selection and use of flux helps prevent oxidation during soldering; it is essential for good wetting and heat transfer. The soldering iron tip must be clean and pre-tinned with solder to ensure rapid heat transfer. Components which dissipate large amounts of heat during operation are sometimes elevated above the PCB to avoid PCB overheating. After inserting a through-hole mounted component, the excess lead is cut off, leaving a length of about the radius of the pad. Plastic or metal mounting clips or holders may be used with large devices to aid heat dissipation and reduce joint stresses.In wave soldering, components are prepped (trimmed or modified) and installed on the PCB. Sometimes, to prevent movement they are temporarily kept in place with small dabs of adhesive or secured with a fixture, then the assembly is passed over flowing solder in a bulk container. This solder flow is forced to produce a standing wave so the whole PCB is not submerged in solder, but rather just touched. The end result is that solder stays on pins and pads, but not on the PCB itself

Our Services:

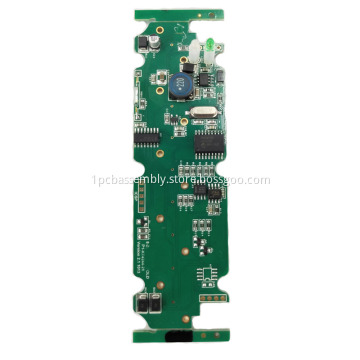

1. PCB Design: One-stop EMS manufacturer, speciallized in designing wireless charging PCBA, bluetooth earphone & Voice box PCBA and other consumer electronics products.

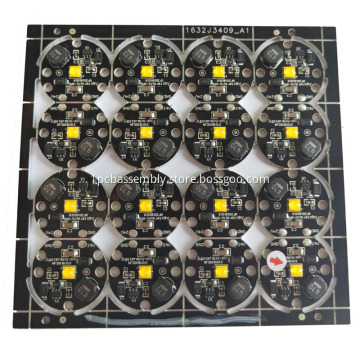

2. PCB Manufacture: Standard FR4 1-36layer PCB, Flex PCB, Rigid-Flex PCB, HDI PCB, Rogers PCB, Metal Core PCB, etc.

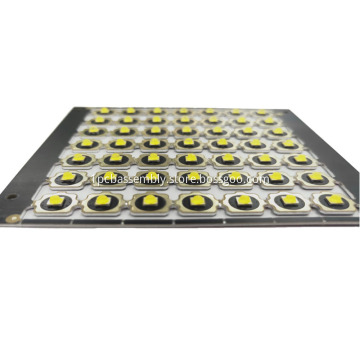

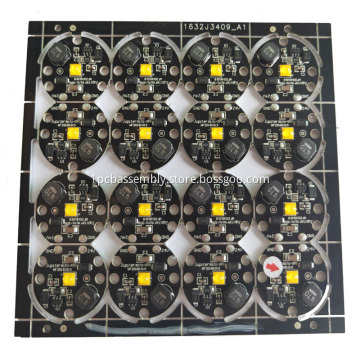

3. PCB Assembly: SMT and THT assembly, available for 01005, fine pitch and BGA assembly.

4. Components Sourcing: Available to source all components shown in BOM file (BOM Kitting), hard to find components and long lead time components, etc.

5. One-Stop Turnkey PCBA Manufacture: PCB design+PCB Manufacture+Components Sourcing+PCB Assembly+Electronic Assembly, or PCB Manufacture+Components sourcing+PCB Assembly, etc.

Technical Capabilities:

|

PCB Manufacture Capabilities |

|

|

Layers |

1-36 layers |

|

Material |

FR-4 (Standard FR4, Mid-Tg FR4, Hi-Tg FR4, Lead free assembly material) , Polymide, Metal Core, Rogers, etc. |

|

Board Thickness |

0.1mm-6.0mm (.016"-.126") |

|

Copper Thickness |

1/2oz-6oz(18um-210um) |

|

Board size |

600mm*1200mm |

|

Min Tracing/Spacing |

0.075mm/0.075mm (3mil/3mil) |

|

Min drilling Hole diameter |

0.15mm(6mil), 0.1mm(4mil)-laser drill |

|

Solder Mask |

LPI, different colors(Green, Green matt, Black, Black Matt, White, Red, Yellow, Blue) |

|

Silkscreen color |

White, Blue, Black, Red, Yellow |

|

Surface finish |

Lead free HASL, immersion gold, golden finger, immersion tin, immersion silver, OSP, Carbon oil, plated hard gold(up to 100u") |

|

Impedance tolerance |

+/-5%~+/-10% |

|

Chamfer of Gold Fingers |

20, 30, 45, 60 |

|

Test |

Flying probe or Testing fixture |

|

PCB Assembly Capabilities |

|

|

Quantity |

From prototype to big volume, no MOQ |

|

Assembly type |

SMT, THT or Hybrid |

|

Parts procurement |

Full turnkey (we provided all components) |

|

Partial turnkey ( Customer provide the main components and we provide the rest) |

|

|

Kitted (Customer provide all components) |

|

|

Component types |

SMT 01005, BGA 0.3mm pitch, QFP 0.3mm pitch, etc. |

|

Test |

Custom testing, ICT, FCT, AOI, Test jig |

Our Team and Office:

Our PCB Manufacture Factory:

Our PCB Assembly Factory:

Customer Visiting

Packing and shipping

FAQ:

Q: What files need for custom PCB manufacture?

A: Gerber or .pcb or .pcbdoc or .brd file is required.

Q: What files need for custom PCB assembly order?

A: Gerber and the BOM files are required, if you have pick&place file, send it to us as well.

Q: What is payment terms acceptable?

A: For new customer and the total amount within 10000usd, 100% payment in advance by PayPal or T/T or WU. For total amount beyond 10000usd, please contact us.

Q: What files need for PCB/PCBA clone services?

A: For PCB/PCBA clone service, send us the pictures for evaluate first, and we will need 1-2 samples of the PCB/PCBA board for copying.

Related Keywords