High Frequency RF Application PCB Rogers PCB

- Payment Type:

- T/T, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Delivery Time:

- 1-20 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, HONGKONG

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen China |

|---|---|

| Productivity: | 500,000pcs per Month |

| Supply Ability: | 500,000pcs per Month |

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO9001, IATF16949, IPC-A-610F |

| HS Code: | 8534009000 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,HONGKONG |

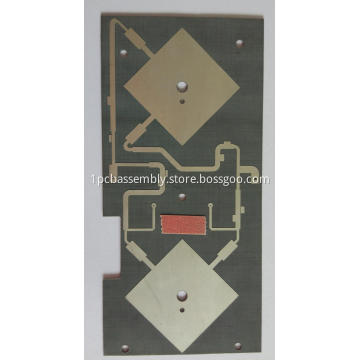

High Frequency RF Application PCB Rogers PCB

High Frequency PCB is the special PCB with higher electromagnetic frequencies, in general, high frequencies can be defined as frequencies above 1 GHz. Its physical properties, precision, and technical parameters are very high, and it is often used in automotive anti-collision systems, satellite systems, radio systems, etc. Special materials are required to achieve the high frequency provided by this type of printed circuit board - any changes in the Er value of these materials can affect the impedance of the board. Many PCB designers turn to Rogers dielectric material for its lower dielectric loss, reduced signal loss, lower cost of circuit fabrication and better suitability for fast-turnaround prototyping applications.

Apart from choosing the appropriate PCB material and determining the correct the value of the Er, designers should take parameter such as conductor width and spacing, substrate constant into consideration. These parameters must be exactly specified and implemented with the highest level of process control.

PCB = printed circuit board and PCBA = printed circuit board assembly. For PCB, it means the copper circuits be printed on a board, and so the main composition of PCB are copper and board.

The copper is the circuits material and the circuits designed by the PCB designers. Depends on the current in the circuits, the PCB copper thickness could be done with 0.5oz-10oz. But the PCB designers need be noted that the copper track width/space need be enlarged with the thickness. For example, the minimum copper track width/space could be 3mil/3mil with 0.5oz, but would be 4mil/4mil with 1oz.

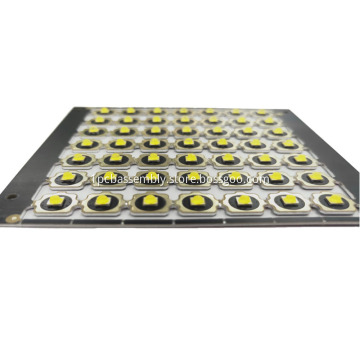

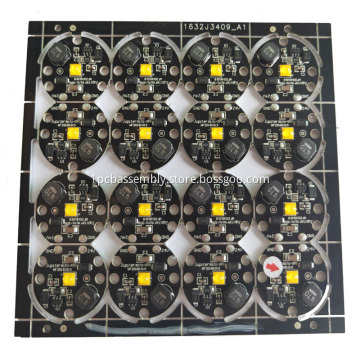

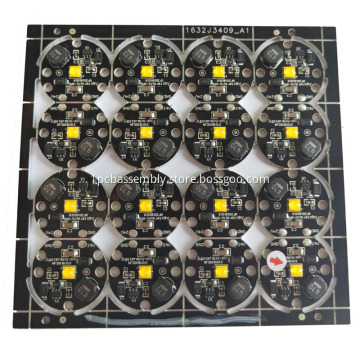

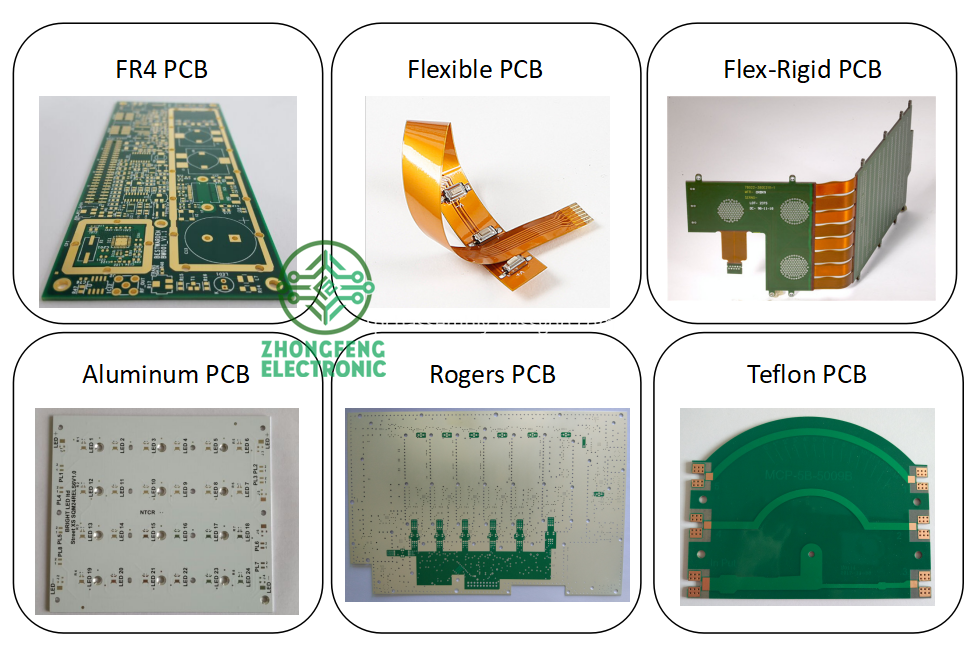

The PCB board could be rigid PCB, could be flex PCB and also could be flex-rigid PCB. And the materials could be FR4, PI, Aluminum, Copper-based, Rogers, Teflon, etc. They have different applications. For example, FR4 PCB is the most commonly used for rigid PCB and almost good for all electronics products; PI is the most commonly used for flex PCB; Aluminum and copper-based have good thermal diffusivity and always used for LED PCB; Rogers PCB and Teflon PCB are always used for high frequency PCB, etc.

We are the one-stop shop for all kinds of PCB manufacture service from PCB prototype to big volume, which could save our customers a lot of time and money.

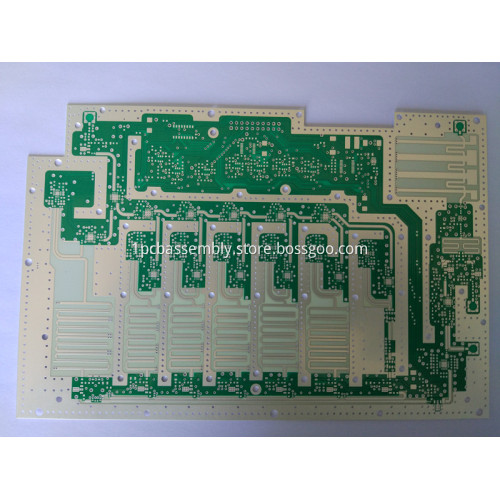

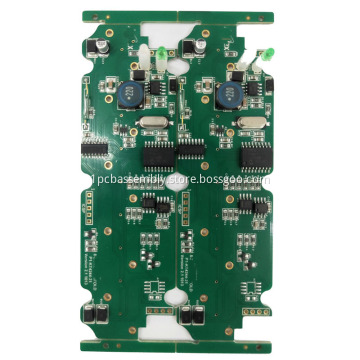

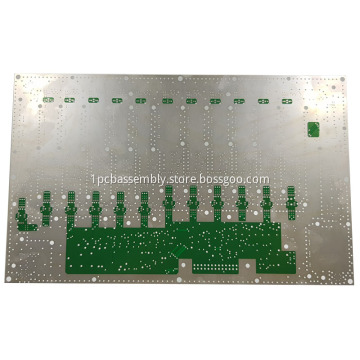

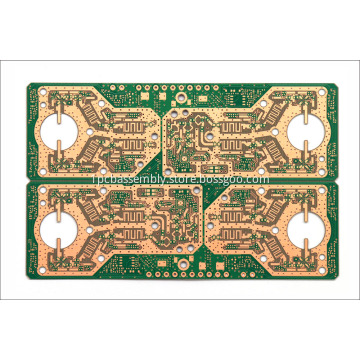

PCB Manufacture Products Show

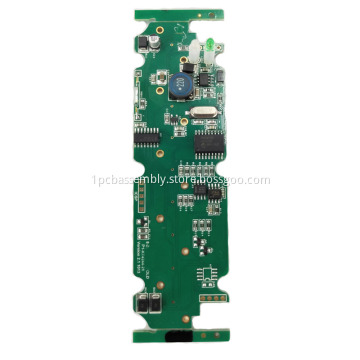

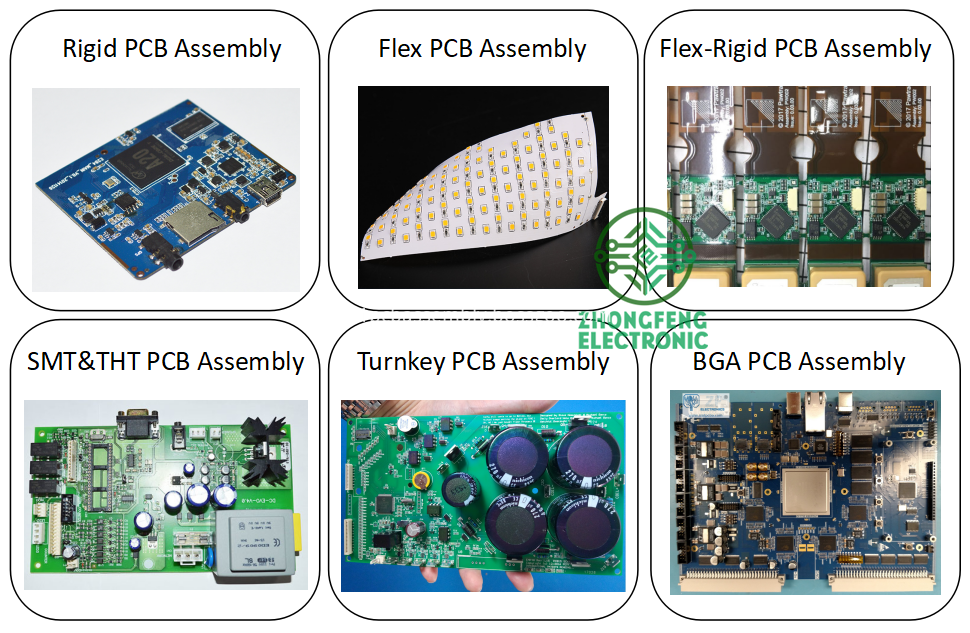

PCB Assembly Products Show

Our Services:

1. PCB Design: One-stop EMS manufacturer, speciallized in designing wireless charging PCBA, bluetooth earphone & Voice box PCBA and other consumer electronics products.

2. PCB Manufacture: Standard FR4 1-36layer PCB, Flex PCB, Rigid-Flex PCB, HDI PCB, Rogers PCB, Metal Core PCB, etc.

3. PCB Assembly: SMT and THT assembly, available for 01005, fine pitch and BGA assembly.

4. Components Sourcing: Available to source all components shown in BOM file (BOM Kitting), hard to find components and long lead time components, etc.

5. One-Stop Turnkey PCBA Manufacture: PCB design+PCB Manufacture+Components Sourcing+PCB Assembly+Electronic Assembly, or PCB Manufacture+Components sourcing+PCB Assembly, etc.

Technical Capabilities:

|

PCB Manufacture Capabilities |

|

|

Layers |

1-36 layers |

|

Material |

FR-4 (Standard FR4, Mid-Tg FR4, Hi-Tg FR4, Lead free assembly material) , Polymide, Metal Core, Rogers, etc. |

|

Board Thickness |

0.1mm-6.0mm (.016"-.126") |

|

Copper Thickness |

1/2oz-6oz(18um-210um) |

|

Board size |

600mm*1200mm |

|

Min Tracing/Spacing |

0.075mm/0.075mm (3mil/3mil) |

|

Min drilling Hole diameter |

0.15mm(6mil), 0.1mm(4mil)-laser drill |

|

Solder Mask |

LPI, different colors(Green, Green matt, Black, Black Matt, White, Red, Yellow, Blue) |

|

Silkscreen color |

White, Blue, Black, Red, Yellow |

|

Surface finish |

Lead free HASL, immersion gold, golden finger, immersion tin, immersion silver, OSP, Carbon oil, plated hard gold(up to 100u") |

|

Impedance tolerance |

+/-5%~+/-10% |

|

Chamfer of Gold Fingers |

20, 30, 45, 60 |

|

Test |

Flying probe or Testing fixture |

|

PCB Assembly Capabilities |

|

|

Quantity |

From prototype to big volume, no MOQ |

|

Assembly type |

SMT, THT or Hybrid |

|

Parts procurement |

Full turnkey (we provided all components) |

|

Partial turnkey ( Customer provide the main components and we provide the rest) |

|

|

Kitted (Customer provide all components) |

|

|

Component types |

SMT 01005, BGA 0.3mm pitch, QFP 0.3mm pitch, etc. |

|

Test |

Custom testing, ICT, FCT, AOI, Test jig |

Our Team and Office:

Our PCB Manufacture Factory:

Our PCB Assembly Factory:

FAQ:

Q: What files need for custom PCB manufacture?

A: Gerber or .pcb or .pcbdoc or .brd file is required.

Q: What files need for custom PCB assembly order?

A: Gerber and the BOM files are required, if you have pick&place file, send it to us as well.

Q: What is payment terms acceptable?

A: For new customer and the total amount within 10000usd, 100% payment in advance by PayPal or T/T or WU. For total amount beyond 10000usd, please contact us.

Q: What files need for PCB/PCBA clone services?

A: For PCB/PCBA clone service, send us the pictures for evaluate first, and we will need 1-2 samples of the PCB/PCBA board for copying.

Related Keywords