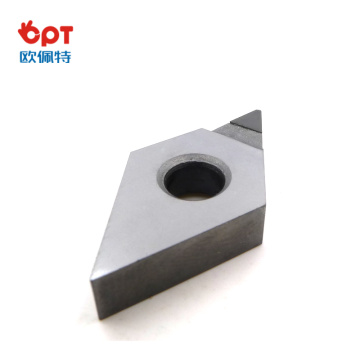

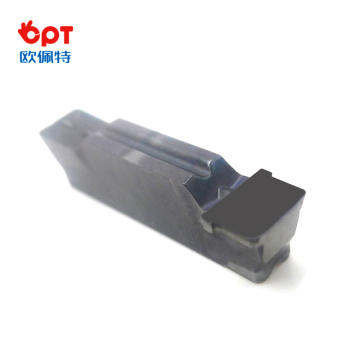

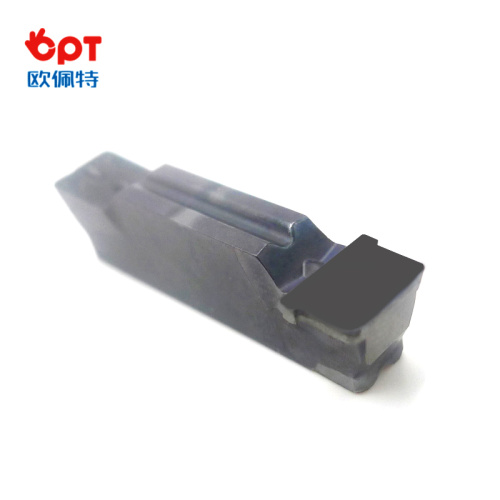

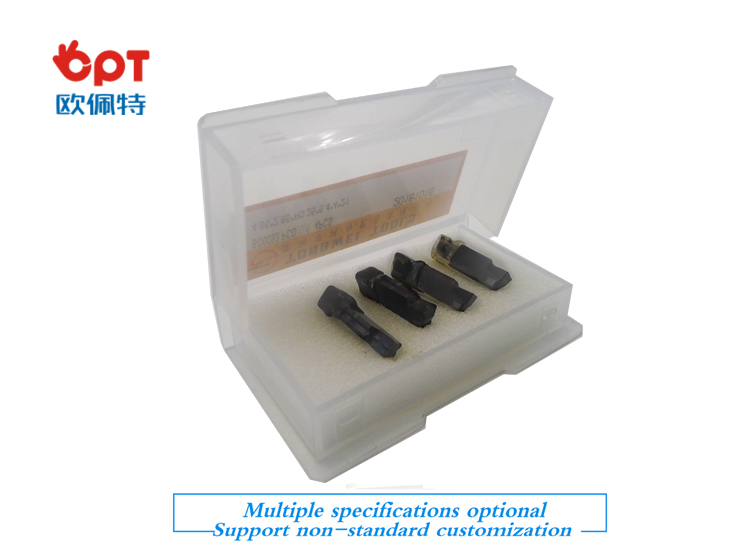

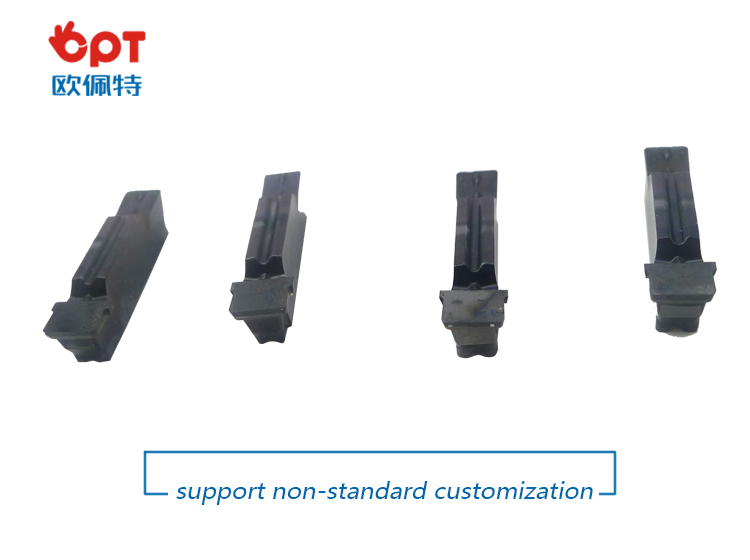

PCD full radius iso grooving and turning inserts

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Yantian, Shekou, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 pcs/month |

| Supply Ability: | 10000 pcs/month |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Yantian,Shekou,Chiwan |

PCD full radius iso grooving and turning inserts

PCD tools usually should adopt a positive cutting angle in order to reduce the cutting force and prevent the occurrence of chipping. However, when processing high-silicon aluminum alloys ,especially when the carbide tool is replaced with a PCD tool for processing, the optimal back angle of the PCD tool is slightly smaller than the back angle taken by the original hard tool.

OPT Cutting Tools designs and manufactures PCD groove tools that are to your specific width and depth requirements. Our engineers can assist in designing special groove, chamfer and form tools to meet the requirements of your project. Chip control designs are available for groove, profile and groove-turn applications. Tolerances of 2 microns are consistently held on our insert geometries.

Advantages:

1. Quality advantage, using precision silver brazing process to ensure your sharpness and precision.

2. Surface treatment advantage, PCD grooving cutter body adopts special anti-rust treatment to keep the new cutter state.

3. Cost-effective advantage, PCD grooving inserts has stable and long service life, unparalleled slotting quality.

Main products:

1.PCD inserts

2.PCD Reamers

3.PCD End Mills

4.Woodworking Tools

5.Cabide Inserts

6.Carbide Drills

7.Carbide End Mills

8. Carbide Taps and so on.

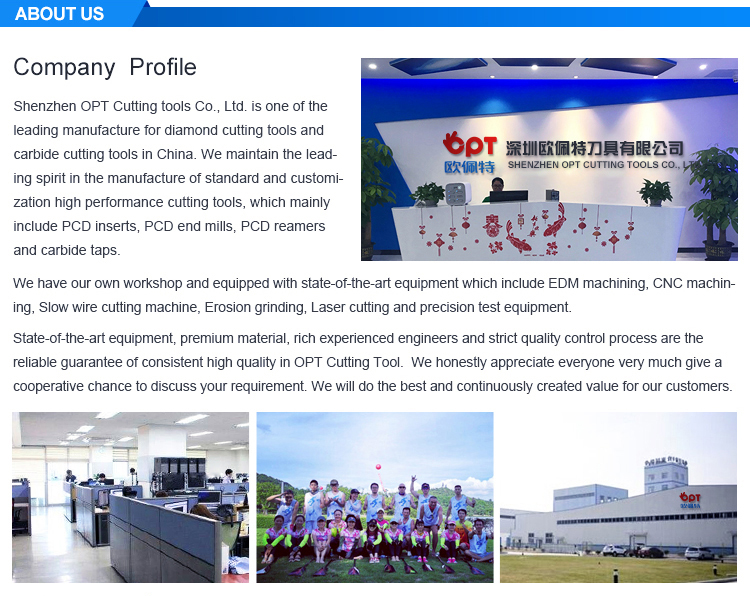

We are a manufacture of cutting tools. We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry.

Premium quality of raw material is used in the production and strict examination during processing with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery. For these years we have been made a large forward in the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords